Additive Manufacturing and 3D Printing in IE Curricula: Preparing Future Engineers

The landscape of manufacturing is undergoing a profound transformation, largely driven by the advent of additive manufacturing, commonly known as 3D printing. Once a niche technology, 3D printing has evolved into a powerful tool that offers unparalleled design freedom, rapid prototyping capabilities, and on-demand production. For Industrial Engineering (IE) programs, ignoring this paradigm shift is no longer an option. Integrating additive manufacturing and 3D printing into IE curricula is crucial for equipping the next generation of engineers with the skills necessary to navigate and lead in this evolving industrial ecosystem.

Table of Contents

- The Transformative Power of 3D Printing in Industrial Engineering

- Integrating Additive Manufacturing into IE Courses

- Benefits for Students and Future Careers

- Challenges and Solutions in Curriculum Development

- Conclusion: Shaping the Future of Industrial Engineering

The Transformative Power of 3D Printing in Industrial Engineering

Traditional manufacturing relies on subtractive methods, removing material from a larger block, or formative processes, shaping material. 3D printing, in contrast, builds objects layer by layer, offering significant advantages such as the ability to create highly complex geometries, customize parts efficiently, and reduce material waste. From an Industrial Engineering perspective, this technology has far-reaching implications across product design, process optimization, supply chain management, and quality control.

For instance, IE principles like lean manufacturing and Six Sigma can be applied to optimize 3D printing processes, just as 3D printing can revolutionize how these principles are implemented in product development. Understanding these synergies is vital for industrial engineers who will be tasked with designing and managing future production systems.

Integrating Additive Manufacturing into IE Courses

The successful integration of additive manufacturing into IE curricula requires a multifaceted approach, spanning theoretical knowledge and practical application.

Core Concepts and Design Principles

Students must grasp the fundamental principles of various 3D printing technologies (FDM, SLA, SLS, DMLS) and the materials they utilize. This includes understanding design for additive manufacturing (DfAM), which dictates how products should be designed to leverage the unique capabilities of 3D printing while considering material properties, structural integrity, and post-processing requirements. Courses should cover topics like CAD software proficiency tailored for additive manufacturing designs, material science specific to polymers and metals used in 3D printing, and process parameter optimization.

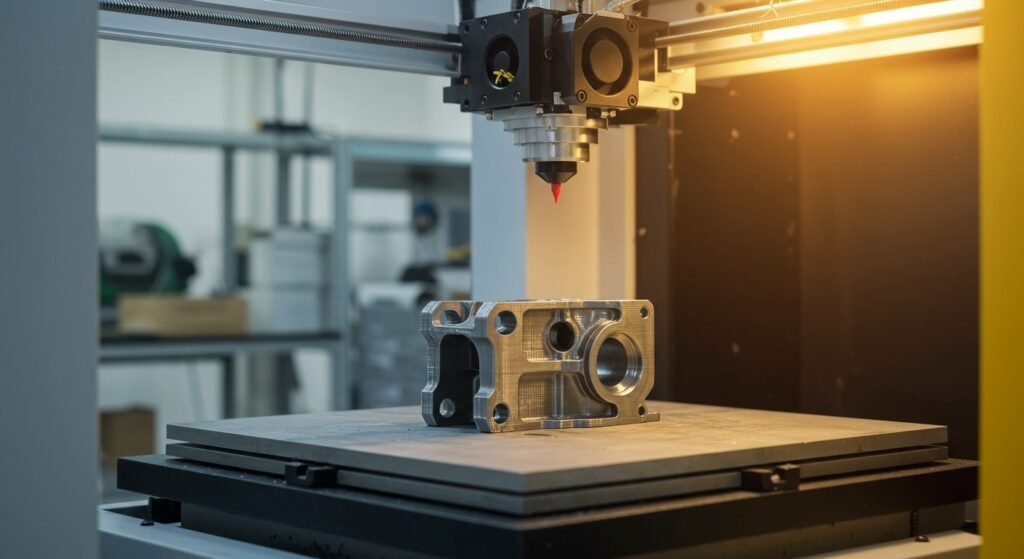

Hands-on Experience with 3D Printing Technologies

Theoretical knowledge must be complemented by practical experience. Industrial Engineering programs should invest in state-of-the-art 3D printers, allowing students to engage in hands-on projects. This could involve designing and printing prototypes, conducting experiments on print parameters, or reverse-engineering existing components for additive manufacturing. Practical exposure helps students understand the real-world challenges and opportunities presented by 3D printing, fostering problem-solving skills and innovative thinking.

Supply Chain and Logistics Optimization

The impact of 3D printing on supply chains is profound. It enables localized production, reduces the need for large inventories, and can streamline logistics for spare parts. IE curricula should explore these aspects, teaching students how to analyze the cost-benefits of distributed manufacturing, manage digital inventories, and optimize the supply chain for on-demand production models. Understanding these shifts prepares them for roles in modern manufacturing and supply chain management.

Benefits for Students and Future Careers

Graduates with a strong understanding of additive manufacturing are highly sought after in industries ranging from aerospace and automotive to healthcare and consumer goods. Integrating 3D printing into IE programs provides students with a competitive edge, fostering skills in innovation, complex problem-solving, and adaptability—qualities essential for the modern engineer. They become proficient in rapid prototyping, iterative design, and optimized production, which are invaluable in today’s fast-paced industrial environment.

| Aspect | Traditional IE Education | IE Education with 3D Printing |

|---|---|---|

| Design Focus | Mass production, standardized parts | Customization, complex geometries |

| Prototyping | Time-consuming, costly tooling | Rapid, iterative, low-cost |

| Supply Chain | Globalized, large inventories | Distributed, on-demand, localized |

| Skillset Acquired | Process optimization, quality control | DfAM, material science, digital fabrication |

Challenges and Solutions in Curriculum Development

While the benefits are clear, integrating 3D printing presents challenges. These include the high initial cost of equipment, the rapid evolution of technology, and the need for faculty training. Universities can overcome these hurdles through strategic partnerships with industry leaders, grant funding, and developing interdisciplinary courses that leverage expertise from various engineering departments.

Furthermore, staying updated with the latest advancements is crucial. Educational institutions can encourage faculty to attend workshops, conferences, and collaborate on research projects related to additive manufacturing. For more insights into the broader applications, consider resources like the Additive Manufacturing Toolbox.

To deepen your understanding of how these technologies fit into a broader context, explore our blog post on Advanced Manufacturing Technologies, which discusses other innovations shaping the future of production.

Conclusion: Shaping the Future of Industrial Engineering

The integration of additive manufacturing and 3D printing into Industrial Engineering curricula is not just an enhancement; it is a necessity. By embracing these technologies, educational institutions can empower students with the knowledge and practical skills required to innovate, optimize, and lead in the next generation of manufacturing. This ensures that future industrial engineers are not merely adapting to change but are actively shaping the future of global production.