Unlocking the Future of Production: Smart Factories and IoT Integration

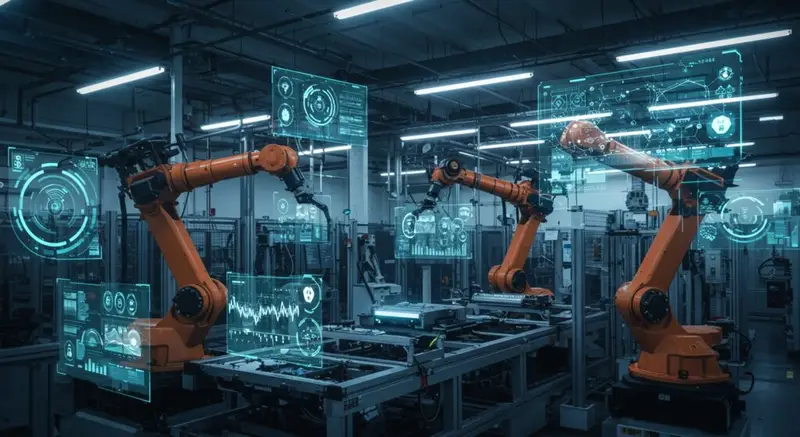

The manufacturing landscape is undergoing a profound transformation, driven by technological advancements that promise unprecedented efficiency and connectivity. At the heart of this revolution lies the concept of Smart Factories and IoT Integration, which represents the convergence of advanced digital technologies with traditional industrial processes. This synergistic approach enables real-time data collection, analysis, and automation, leading to optimized production, reduced downtime, and enhanced decision-making. As industries strive for greater agility and sustainability, understanding the intricacies of this integration becomes paramount.

Table of Contents

- What Are Smart Factories?

- The Pivotal Role of IoT in Smart Manufacturing

- Key Benefits of Smart Factories and IoT Integration

- Challenges and Considerations

- The Future Landscape: Industrial Engineering Trends

- Conclusion

What Are Smart Factories?

A smart factory is a highly digitized and connected manufacturing facility that leverages cutting-edge technologies like the Internet of Things (IoT), artificial intelligence (AI), machine learning (ML), big data analytics, and robotics. Unlike traditional factories, smart factories can self-optimize performance, predict maintenance needs, and adapt to changing demands with minimal human intervention. This shift towards intelligent, automated systems enhances productivity, reduces waste, and improves product quality across the entire value chain.

The Pivotal Role of IoT in Smart Manufacturing

The Internet of Things (IoT) is the backbone of Smart Factories and IoT Integration. It involves a network of interconnected sensors, devices, machines, and software that collect and exchange data in real-time. In a smart factory, IoT sensors embedded in machinery monitor everything from temperature and pressure to vibration and energy consumption. This constant flow of data provides invaluable insights into operational performance, enabling predictive maintenance, quality control, and optimized resource allocation. For instance, sensors can detect anomalies that indicate impending equipment failure, allowing for proactive repairs before costly breakdowns occur.

IoT Devices and Their Applications in Manufacturing

| IoT Device Type | Primary Application | Key Benefit |

|---|---|---|

| Environmental Sensors | Monitoring temperature, humidity, air quality | Optimizes production conditions, ensures product quality |

| Vibration Sensors | Detecting machine wear and tear | Enables predictive maintenance, extends machine lifespan |

| Energy Meters | Tracking power consumption of machinery | Identifies energy waste, reduces operational costs |

| RFID Tags/Readers | Asset tracking, inventory management | Improves supply chain visibility, reduces loss |

| Smart Cameras | Quality inspection, security monitoring | Automates defect detection, enhances safety |

Key Benefits of Smart Factories and IoT Integration

The integration of IoT into factory operations yields a multitude of benefits:

- Enhanced Efficiency and Productivity: Real-time data and automation streamline workflows, minimize idle time, and optimize production schedules.

- Predictive Maintenance: IoT sensors anticipate equipment failures, allowing for timely repairs and significantly reducing unplanned downtime. This is a game-changer for manufacturing uptime.

- Improved Quality Control: Continuous monitoring of production parameters ensures consistent product quality and identifies defects early in the process.

- Cost Reduction: Optimized resource utilization, reduced waste, and lower maintenance costs contribute to significant savings.

- Better Supply Chain Management: Real-time tracking of materials and finished goods enhances transparency and responsiveness in the supply chain. Learn more about industrial IoT standards at ISA Global ISA.org.

- Increased Safety: Automation of hazardous tasks and real-time monitoring of environmental conditions contribute to a safer working environment.

Challenges and Considerations

While the benefits are compelling, implementing smart factory solutions with IoT integration comes with challenges. Data security and privacy are paramount concerns, as vast amounts of sensitive operational data are collected and transmitted. Interoperability between different systems and legacy equipment can also be a hurdle. Furthermore, there’s a need for a skilled workforce capable of managing and interpreting complex data, necessitating significant investment in training and talent development. Organizations must also consider the initial capital expenditure required for new technologies and infrastructure upgrades.

The Future Landscape: Industrial Engineering Trends

The evolution of smart factories continues with emerging trends that will further reshape industrial engineering. Artificial intelligence and machine learning are increasingly used for advanced analytics, process optimization, and even autonomous decision-making. The rise of digital twins, virtual replicas of physical assets and processes, allows for simulations and predictive modeling. Edge computing is gaining traction by processing data closer to its source, reducing latency and bandwidth usage. These innovations promise even greater levels of automation, efficiency, and intelligence in manufacturing. For a deeper dive into specific applications, read our article on AI in Manufacturing.

Conclusion

The journey towards fully realized smart factories, powered by robust Smart Factories and IoT Integration, is not merely an upgrade but a fundamental shift in how industries operate. By embracing these advanced technologies, manufacturers can unlock unprecedented levels of efficiency, innovation, and competitiveness. While challenges exist, the long-term benefits of enhanced productivity, reduced costs, and a more sustainable future make this integration an indispensable component of modern industrial strategy. The future of manufacturing is undeniably smart, connected, and driven by data.