Process Optimization with Simulation is a powerful methodology that leverages digital models to analyze and improve business processes before real-world implementation. In today’s competitive landscape, organizations are constantly seeking ways to enhance efficiency, reduce costs, and accelerate decision-making. Simulation offers a safe, virtual environment to test new strategies, identify bottlenecks, and forecast outcomes without disrupting actual operations. This innovative approach is transforming how industries from manufacturing to healthcare tackle complex operational challenges, making it an indispensable tool for achieving operational excellence and sustainable growth.

Table of Contents

- What is Process Optimization with Simulation?

- The Benefits of Implementing Process Optimization with Simulation

- Key Steps in Simulation-Based Process Optimization

- Real-World Applications and Current Trends

- Challenges and How to Overcome Them

- Conclusion

What is Process Optimization with Simulation?

At its core, Process Optimization with Simulation involves creating a computer model that mimics the behavior of a real-world system or process. This model incorporates various elements such as resources, tasks, queues, and decision points, allowing engineers and analysts to observe how the process flows under different conditions. Unlike static analytical methods, simulation accounts for variability and randomness, providing a dynamic and realistic representation. It enables users to ask “what-if” questions, testing the impact of changes – whether it’s adding more staff, rearranging a production line, or altering a customer service protocol – without the costly and disruptive trial-and-error in a live environment. Common types include Discrete Event Simulation (DES), which focuses on individual events in a system over time, and Agent-Based Modeling (ABM), which simulates the interactions of autonomous agents.

The Benefits of Implementing Process Optimization with Simulation

Embracing simulation for process optimization yields a multitude of advantages that directly impact an organization’s bottom line and strategic capabilities.

Cost Savings and ROI

One of the most compelling benefits is the potential for significant cost reductions. By identifying inefficiencies, resource bottlenecks, and excessive waiting times in a virtual environment, businesses can eliminate waste before it occurs in reality. This includes optimizing inventory levels, reducing overtime, and making more informed capital expenditure decisions. The return on investment (ROI) from a well-executed simulation project can be substantial, often outweighing the initial setup costs within a short period.

Risk Mitigation and Scenario Testing

Simulation provides a risk-free sandbox for experimentation. Organizations can test radical changes, new technologies, or different operational strategies without jeopardizing current operations or incurring high costs. This allows for the identification of potential failures, unexpected outcomes, and system vulnerabilities in advance, enabling proactive mitigation strategies to be developed.

Improved Decision Making

With data-driven insights generated by simulations, decision-makers can move beyond guesswork. The ability to visualize process flow, analyze performance metrics, and compare different scenarios empowers leaders to make more confident and effective choices that are backed by quantitative evidence. This leads to more robust and sustainable improvements.

Enhanced Operational Efficiency

Ultimately, simulation leads to smoother, faster, and more productive processes. By optimizing resource allocation, reducing bottlenecks, and streamlining workflows, businesses can significantly improve their throughput and overall operational efficiency. This translates into higher customer satisfaction, faster time-to-market, and increased competitiveness.

| Metric | Before Simulation | After Simulation (Proposed) |

|---|---|---|

| Average Throughput (units/day) | 150 | 190 |

| Average Lead Time (hours) | 2.5 | 0.8 |

| Machine Utilization (%) | 65 | 88 |

| WIP Inventory (Avg. units) | 40 | 15 |

| Estimated Cost Savings (per year) | N/A | $100,000+ |

Key Steps in Simulation-Based Process Optimization

A systematic approach is crucial for successful process optimization with simulation. Here are the typical phases:

Define Project Scope and Goals

Clearly articulate the problem to be solved, the boundaries of the system to be simulated, and the specific objectives and performance metrics to be improved. Without well-defined goals, the simulation can become an aimless exercise.

Data Collection and Analysis

Gather accurate and relevant data on the existing process, including arrival rates, processing times, resource availability, decision rules, and historical performance. This data forms the foundation of a realistic simulation model.

Model Development and Validation

Build the simulation model using specialized software. Leading tools like AnyLogic Simulation Software or Arena provide robust environments for this. Once built, the model must be rigorously validated against real-world data to ensure it accurately reflects the system’s behavior.

Experimentation and Analysis

Run various scenarios (“what-if” analyses) by altering process parameters, resource levels, or operational rules within the model. Analyze the results to identify optimal configurations and predict their impact on performance metrics.

Implementation and Monitoring

Based on the simulation insights, implement the recommended changes in the real system. Crucially, continuously monitor the performance of the updated process to ensure the desired improvements are realized and sustained. This iterative approach allows for further refinements.

Real-World Applications and Current Trends

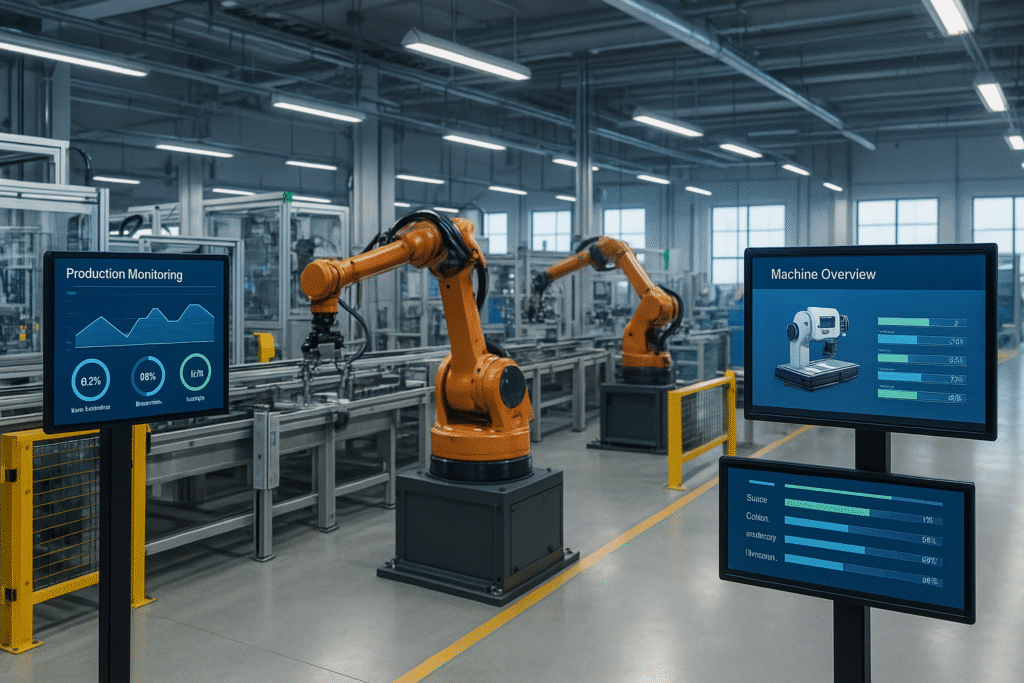

Process Optimization with Simulation is not confined to a single industry. In manufacturing, it’s used to optimize production lines and supply chains. In healthcare, it aids in improving patient flow and resource allocation. Logistics companies use it to streamline distribution networks, while service industries enhance customer experience by optimizing call center operations or retail layouts. The field is continuously evolving, with trends like integrating simulation with Big Data, AI, and digital twins becoming increasingly prevalent, pushing the boundaries of what’s possible in industrial engineering.

Challenges and How to Overcome Them

While powerful, simulation isn’t without its challenges. Data quality can be a significant hurdle; inaccurate or insufficient data can lead to misleading model results. Overcoming this requires diligent data collection and cleansing. Model complexity can also be an issue, leading to long development times. Starting with a simplified model and iteratively adding detail can mitigate this. Finally, resistance to change within an organization can hinder implementation, emphasizing the need for clear communication of benefits and stakeholder involvement from the outset.

Conclusion

Process Optimization with Simulation stands as a cornerstone for modern operational excellence. By providing a safe, cost-effective, and insightful way to test and refine processes, it empowers organizations to make smarter decisions, mitigate risks, and achieve unprecedented levels of efficiency and productivity. Embracing this technology is not just about optimizing current operations; it’s about building a more resilient, agile, and future-proof business capable of navigating the complexities of tomorrow’s market.