Table of Contents

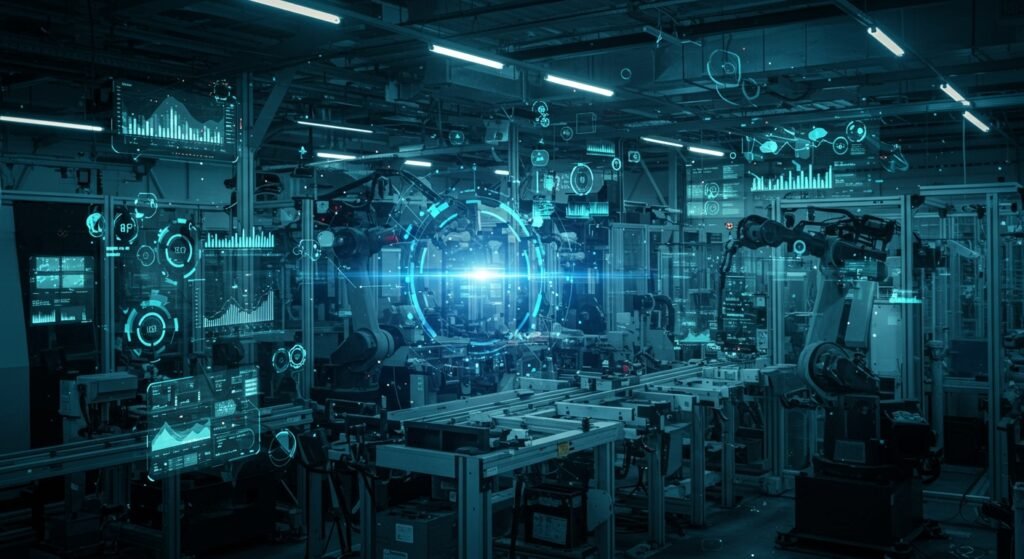

The manufacturing landscape is undergoing a profound transformation, driven by advancements in digital technology. At the forefront of this revolution are Smart Factories and IoT Integration, merging the physical and digital worlds to create highly efficient, interconnected, and adaptive production environments. This shift promises not only to optimize current operations but also to unlock unprecedented opportunities for innovation and growth. By harnessing the power of the Internet of Things (IoT), manufacturers can gain real-time insights, automate complex processes, and make data-driven decisions that dramatically enhance productivity and competitiveness.

What are Smart Factories?

Smart factories are highly digitized and connected production facilities that leverage advanced technologies such as IoT, artificial intelligence (AI), big data analytics, and robotics to create a self-optimizing manufacturing system. Unlike traditional factories, smart factories are characterized by their ability to collect and analyze vast amounts of data from various sources, allowing for predictive insights, automated adjustments, and continuous improvement across the entire production cycle. This dynamic environment enables unprecedented levels of flexibility and responsiveness to market demands.

The Role of IoT in Smart Manufacturing

At the heart of a smart factory’s intelligence lies the Internet of Things (IoT). IoT devices, ranging from sensors embedded in machinery to smart cameras and RFID tags, continuously collect data on performance, environmental conditions, product quality, and more. This data is then transmitted to central systems for analysis, providing a comprehensive, real-time view of operations. This connectivity facilitates communication between machines, systems, and even products, enabling a truly integrated and responsive manufacturing ecosystem. The proliferation of connected devices transforms raw data into actionable intelligence, driving efficiency and innovation.

Key Benefits of IoT Integration in Smart Factories

The adoption of IoT in manufacturing offers a myriad of advantages that go beyond simple automation. The profound impact of Smart Factories and IoT Integration can be seen across various operational aspects, leading to significant improvements in efficiency, quality, and cost-effectiveness.

Enhanced Operational Efficiency

IoT sensors provide real-time data on machine performance, energy consumption, and production bottlenecks. This immediate visibility allows managers to identify inefficiencies quickly and make informed decisions to optimize processes, reduce waste, and increase throughput. Automation capabilities, powered by IoT, streamline repetitive tasks, freeing up human workers for more complex and value-added activities. For more on digital transformation in industry, see our article on digital transformation benefits.

Predictive Maintenance and Downtime Reduction

One of the most impactful benefits is the shift from reactive to proactive maintenance. IoT sensors can monitor machine health parameters like vibration, temperature, and pressure. By analyzing this data, predictive algorithms can forecast potential equipment failures before they occur, allowing for scheduled maintenance and preventing costly unplanned downtime. This capability significantly extends the lifespan of machinery and ensures continuous operation.

Improved Quality Control

IoT devices can monitor product quality at every stage of production, identifying defects or deviations from specifications in real-time. This immediate feedback loop allows for instant adjustments to the manufacturing process, minimizing scrap rates and ensuring a higher standard of finished goods. Data from sensors can also trace product origins and conditions, enhancing traceability and compliance.

Supply Chain Optimization

Beyond the factory floor, IoT extends its reach to the entire supply chain. Real-time tracking of raw materials and finished products, coupled with demand forecasting based on actual consumption data, leads to optimized inventory levels and more efficient logistics. This ensures that materials are available when needed and products reach customers on time, reducing holding costs and improving customer satisfaction. Learn more about the broader implications of these technological shifts at the World Economic Forum’s insights on the Fourth Industrial Revolution.

Here’s a summary of key benefits:

| Benefit Category | Description | Impact on Operations |

|---|---|---|

| Operational Efficiency | Real-time data for process optimization | Reduced waste, increased throughput |

| Predictive Maintenance | Sensors forecast equipment failures | Minimized downtime, extended asset life |

| Quality Control | In-process defect detection | Reduced scrap, higher product quality |

| Supply Chain | Real-time tracking and forecasting | Optimized inventory, improved logistics |

Challenges and Solutions for Implementation

While the benefits are clear, implementing Smart Factories and IoT Integration comes with its own set of challenges. Addressing these proactively is crucial for successful adoption.

Data Security and Privacy

Connecting vast numbers of devices generates immense amounts of data, which also presents significant security risks. Protecting sensitive operational data and intellectual property from cyber threats is paramount. Solutions include robust encryption protocols, network segmentation, regular security audits, and adherence to international data privacy regulations.

Legacy System Integration

Many existing factories operate with older, proprietary equipment that wasn’t designed for IoT connectivity. Integrating these legacy systems with new IoT platforms can be complex and costly. Solutions often involve the use of industrial gateways, middleware, and data standardization techniques to bridge the gap between old and new technologies, allowing for a phased transition rather than a complete overhaul.

The Future of Industrial Engineering

The ongoing evolution of Smart Factories and IoT Integration is fundamentally reshaping industrial engineering. The future will see even more sophisticated integration of AI and machine learning, leading to fully autonomous operations, hyper-personalization of products, and truly adaptive supply chains. As technology continues to advance, the smart factory will not just be a place of production but a living, learning entity that continuously optimizes itself for maximum performance and sustainability. This represents a thrilling new chapter for industrial engineering, promising unprecedented levels of efficiency and innovation.