Unlocking Efficiency: 7 Breakthroughs of Industrial Engineering in Smart Manufacturing

The landscape of global production is undergoing a profound transformation, driven by the convergence of advanced digital technologies and traditional manufacturing principles. At the heart of this evolution is the critical role of Industrial Engineering in Smart Manufacturing. This field is no longer just about optimizing isolated processes; it’s about orchestrating entire interconnected systems, ensuring seamless data flow, intelligent automation, and human-machine collaboration.

Table of Contents

- Introduction to Smart Manufacturing and IE

- The Core Role of Industrial Engineering in Smart Manufacturing

- Key Technologies and IE Applications

- Tangible Benefits: Why IE is Crucial for Smart Manufacturing Success

- Challenges and Future Trends

- Real-World Impact and Applications

- Conclusion

Introduction to Smart Manufacturing and IE

Smart Manufacturing, often synonymous with Industry 4.0, represents a paradigm shift from traditional mass production to highly flexible, interconnected, and adaptive systems. It leverages technologies like the Internet of Things (IoT), artificial intelligence (AI), big data analytics, and cloud computing to create factories that can self-optimize and respond in real-time to changing demands. Industrial engineers are the architects of this transformation, applying their expertise in system design, process improvement, and human factors to integrate these complex technologies effectively.

The Core Role of Industrial Engineering in Smart Manufacturing

Industrial engineers are uniquely positioned to bridge the gap between technological innovation and practical application on the factory floor. Their core competencies – lean principles, Six Sigma methodologies, operations research, and human factors engineering – are indispensable for designing, implementing, and managing smart manufacturing systems. They analyze the entire value stream, from raw materials to finished products, identifying bottlenecks, reducing waste, and improving overall system throughput. Their holistic perspective ensures that technology serves the strategic objectives of the business, rather than being implemented in isolation.

Key Technologies and IE Applications

The successful deployment of smart manufacturing hinges on the effective integration of several cutting-edge technologies. Industrial engineers play a pivotal role in optimizing their use:

Data Analytics and Artificial Intelligence

Smart factories generate vast amounts of data. Industrial engineers utilize data analytics and AI tools to extract actionable insights, predict equipment failures, optimize production schedules, and enhance quality control. They design the metrics and dashboards necessary for real-time performance monitoring and continuous improvement.

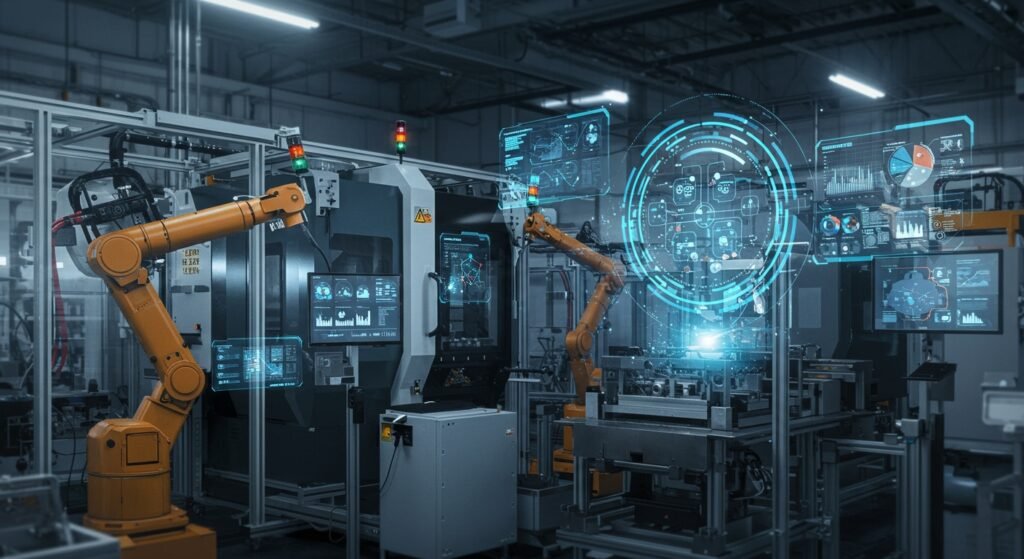

Automation and Robotics

From collaborative robots (cobots) working alongside humans to fully automated assembly lines, automation is a cornerstone of smart manufacturing. IEs design ergonomic workstations, optimize robot paths, and develop human-robot interaction protocols to maximize efficiency and safety while leveraging automation for repetitive or hazardous tasks.

Smart Supply Chain Optimization

A smart factory is only as efficient as its supply chain. Industrial engineers apply their analytical skills to optimize inventory levels, streamline logistics, and enhance supplier collaboration using real-time data from IoT devices and advanced forecasting models. This creates a resilient and responsive supply network.

Tangible Benefits: Why IE is Crucial for Smart Manufacturing Success

The integration of industrial engineering principles into smart manufacturing yields significant advantages:

| Aspect | Traditional Manufacturing (without IE focus) | Smart Manufacturing (with IE focus) |

|---|---|---|

| Efficiency | Limited optimization, siloed processes | Holistic system optimization, real-time adjustments |

| Flexibility | Rigid production lines, slow adaptation | Agile and reconfigurable systems, rapid product changes |

| Quality | Inspection-based, post-production defect identification | Predictive quality control, in-process anomaly detection |

| Resource Usage | Higher waste, less energy efficiency | Minimized waste, optimized energy consumption |

| Decision Making | Reactive, based on historical data | Proactive, data-driven, real-time insights |

Challenges and Future Trends

Despite the immense potential, implementing smart manufacturing solutions comes with challenges, including cybersecurity risks, the need for a skilled workforce, and significant initial investment. Future trends in industrial engineering and smart manufacturing include the increasing adoption of digital twins for simulation and optimization, greater human-AI collaboration, and the development of more sustainable and circular manufacturing processes. For more insights into the broader industrial landscape, you might want to explore resources like the Institute of Industrial and Systems Engineers (IISE).

Real-World Impact and Applications

The application of industrial engineering in smart manufacturing is already evident across various sectors. For example, in the automotive industry, IEs are designing assembly lines that can rapidly switch between different vehicle models, using AI to predict maintenance needs for robotic arms. In the electronics sector, they are optimizing highly automated component placement processes, leveraging big data to enhance yield rates. These advancements demonstrate a clear path towards more resilient and efficient production. You can learn more about specific implementation strategies in our article on Digital Transformation Strategies for Manufacturers.

Conclusion

Industrial Engineering in Smart Manufacturing is not merely an academic concept; it is the practical backbone enabling industries to harness the power of digital transformation. By combining foundational engineering principles with cutting-edge technologies, industrial engineers are building the factories of tomorrow – efficient, agile, and intelligent systems capable of responding to the complexities of a dynamic global market. Their expertise ensures that the promise of Industry 4.0 translates into tangible, sustainable competitive advantages.