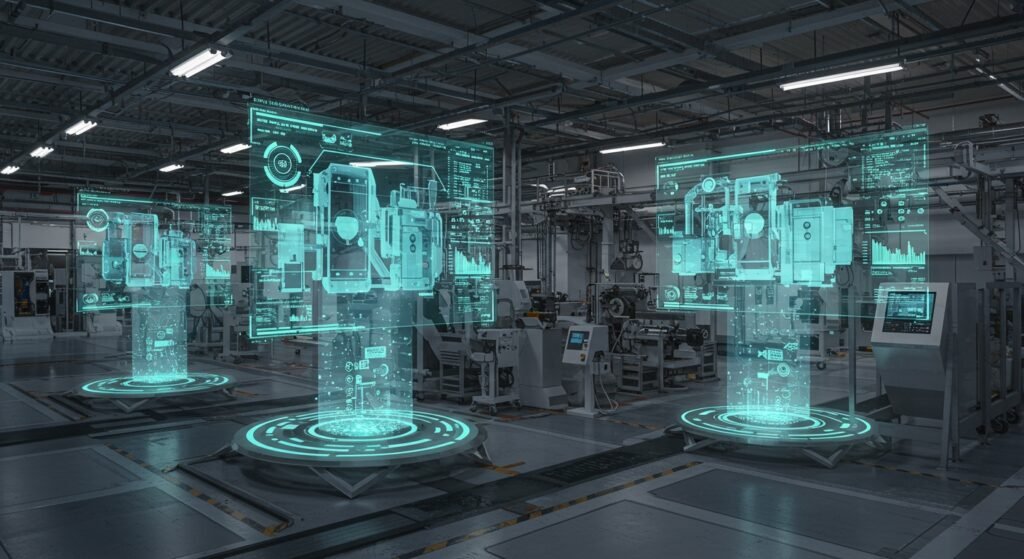

In the realm of modern manufacturing and industrial operations, the concept of Digital Twins in Industrial Systems has emerged as a truly transformative technology. Imagine having a precise virtual replica of a physical asset, process, or system that updates in real-time, allowing for unparalleled insights, predictive capabilities, and optimized performance. This isn’t science fiction; it’s the reality brought forth by digital twin technology, fundamentally changing how industries operate.

Table of Contents

- What Are Digital Twins?

- Key Applications of Digital Twins in Industrial Systems

- Unlocking Benefits for Industrial Operations

- Challenges and Future Trends

- Conclusion

What Are Digital Twins?

A digital twin is essentially a virtual model designed to accurately reflect a physical object, process, or service. For industrial systems, this means creating a digital counterpart of a piece of machinery, an entire production line, or even an entire factory. This virtual model is continuously fed with real-time data from sensors attached to its physical twin. This constant data flow ensures the digital twin behaves and responds exactly like its physical counterpart, offering a dynamic and evolving representation. This real-time synchronization is what makes Digital Twins in Industrial Systems so powerful, providing a living laboratory for testing, analysis, and optimization without disrupting physical operations. The integration of IoT, AI, and machine learning further enhances their capabilities.

Key Applications of Digital Twins in Industrial Systems

The versatility of digital twins allows for their application across various facets of industrial operations, bringing significant advantages.

Predictive Maintenance

One of the most impactful applications is in predictive maintenance. By continuously monitoring the health and performance of machinery through their digital twins, industries can anticipate equipment failures before they occur. This allows for scheduled maintenance, reducing costly downtime and extending the lifespan of critical assets. Data points like temperature, vibration, and pressure are analyzed in the digital realm to predict potential issues with remarkable accuracy.

Process Optimization

Digital twins enable engineers to simulate and analyze complex industrial processes in a virtual environment. This allows for the identification of bottlenecks, inefficiencies, and potential improvements without affecting real-world production. Adjustments can be tested and validated digitally, leading to optimized workflows, reduced waste, and increased throughput. This level of insight is invaluable for continuous improvement initiatives.

Product Lifecycle Management (PLM)

From design to disposal, digital twins can track and simulate the entire lifecycle of a product or asset. This facilitates better design decisions, more efficient prototyping, and improved quality control. Manufacturers can understand how a product will perform under various conditions before it even leaves the production line, greatly minimizing risks and maximizing product efficacy.

Remote Monitoring and Control

For globally dispersed operations, digital twins provide a centralized platform for remote monitoring and control. Engineers can access real-time data and even operate machinery from thousands of miles away, ensuring continuous oversight and rapid response to emerging issues. This capability is particularly vital for hazardous environments or operations in remote locations.

Unlocking Benefits for Industrial Operations

The adoption of digital twins translates into a multitude of tangible benefits for industrial enterprises. These include enhanced operational efficiency, significant cost reductions, improved safety, and faster innovation cycles. The ability to simulate “what-if” scenarios empowers decision-makers with data-driven insights, leading to more informed and strategic choices.

| Feature | Traditional Industrial System | Digital Twin Integrated System |

|---|---|---|

| Maintenance | Reactive (breakdown fixes) | Proactive (predictive & prescriptive) |

| Troubleshooting | On-site, manual diagnosis | Remote, data-driven simulation |

| Optimization | Trial-and-error, limited data | Simulation-based, real-time data |

| Risk Management | High potential for unexpected failures | Reduced risks, simulated failure analysis |

| Operational Visibility | Limited, often siloed | Comprehensive, real-time, unified |

Challenges and Future Trends

While the promise of digital twins is immense, their implementation comes with challenges. Data integration from disparate sources, ensuring robust cybersecurity measures, and the initial investment in IoT infrastructure are significant hurdles. However, as technology evolves, these barriers are steadily decreasing. The future of Digital Twins in Industrial Systems is bright, with trends pointing towards greater integration with augmented reality (AR) for interactive maintenance, wider adoption in smart cities, and increasingly sophisticated AI models driving even deeper insights. For more in-depth technical details on the underlying technologies, you might explore resources like The Industrial Internet Consortium. Understanding how these innovations tie into broader shifts like Industry 4.0 is key to grasping their full impact.

Conclusion

Digital Twins in Industrial Systems are no longer just a theoretical concept but a practical, indispensable tool transforming industries worldwide. From boosting efficiency and reducing costs to enhancing safety and accelerating innovation, the advantages are clear. As industries continue their journey of digital transformation, the digital twin will undoubtedly remain at the forefront, shaping the factories, processes, and products of tomorrow.