Reducing Operational Costs via IE: An Unbeatable Guide

In today’s competitive business landscape, the imperative to streamline operations and enhance profitability is paramount. For many organizations, the answer lies in effectively Reducing Operational Costs via IE, or Industrial Engineering. This discipline focuses on optimizing complex processes, systems, and organizations by developing, improving, and implementing integrated systems of people, money, knowledge, information, equipment, energy, and material.

Table of Contents

- What is Industrial Engineering (IE)?

- Key IE Strategies for Significant Cost Reduction

- Implementing IE for Maximum Cost Savings

- Case Studies and Measurable Results

- The Future of IE in Cost Management

What is Industrial Engineering (IE)?

Industrial Engineering is a branch of engineering that deals with the optimization of complex processes or systems. It is concerned with the development, improvement, implementation, and evaluation of integrated systems of people, money, knowledge, information, equipment, energy, and material. Unlike other engineering disciplines that focus on product design or physical processes, IE is unique in its focus on human factors and the overall efficiency of an entire system.

The core objective of IE is to eliminate waste in all its forms – time, material, motion, defects, and overproduction – thereby enhancing productivity and, crucially, reducing operational expenses. This makes it a powerful tool for any organization looking at financial health and sustainable growth.

Key IE Strategies for Significant Cost Reduction

Industrial engineers employ a range of methodologies and tools to identify inefficiencies and implement cost-saving measures. Here are some of the most impactful:

Process Optimization and Redesign

At the heart of IE is the analysis and improvement of processes. This involves mapping current processes, identifying bottlenecks, redundancies, and non-value-added activities, and then redesigning them for greater efficiency. Tools like flowcharts, value stream mapping, and process simulation are often used. By streamlining workflows, companies can achieve substantial savings in labor, time, and resources.

Waste Reduction (Lean Principles)

Inspired by the Toyota Production System, Lean principles are fundamental to IE’s approach to cost reduction. They aim to eliminate the seven types of waste: defects, overproduction, waiting, non-utilized talent, transportation, inventory, motion, and extra processing. Implementing Lean practices directly impacts the bottom line by using fewer resources to produce more value. Many resources are available to learn more about Lean methodologies from reputable sources.

Supply Chain Optimization

A significant portion of operational costs can be tied to the supply chain. IE principles are applied to optimize logistics, inventory management, warehousing, and transportation. By improving lead times, reducing inventory holding costs, and optimizing delivery routes, companies can achieve substantial savings. This also includes negotiating better terms with suppliers based on optimized demand forecasting.

Quality Improvement (Six Sigma)

Poor quality leads to rework, scrap, warranty claims, and customer dissatisfaction—all of which are costly. Six Sigma, often integrated with Lean (Lean Six Sigma), is a data-driven methodology used to eliminate defects in any process. By reducing variations and improving quality, IE ensures that products and services meet specifications consistently, thus avoiding the hidden costs of poor quality.

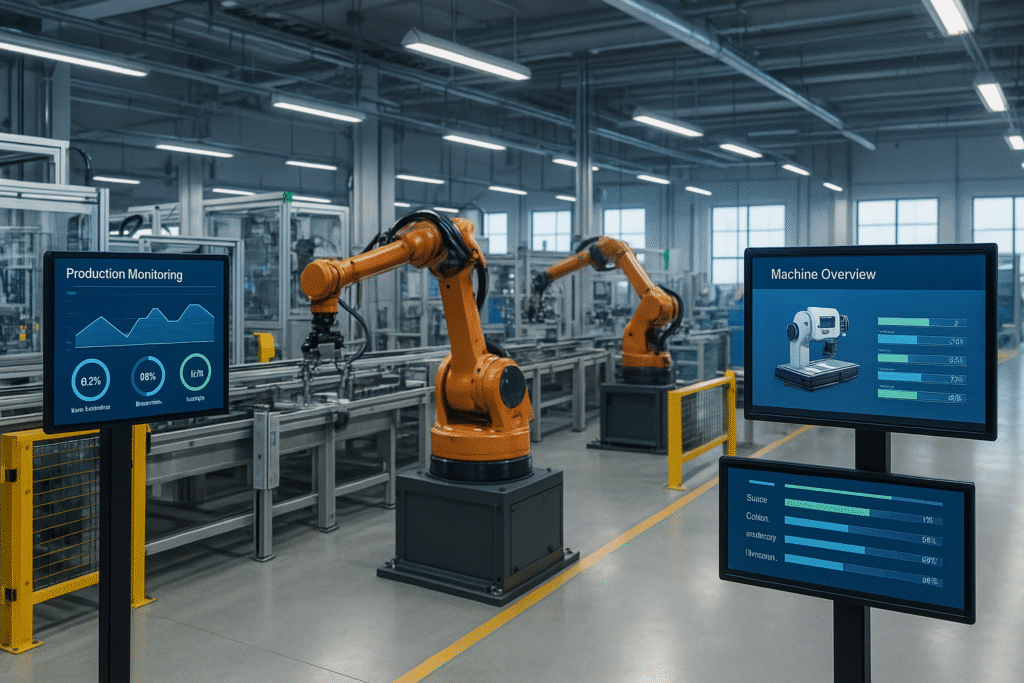

Automation and Technology Integration

While often requiring an upfront investment, strategic automation can lead to significant long-term operational cost reductions. Industrial engineers assess where automation will yield the greatest returns, considering factors like repetitive tasks, safety hazards, and precision requirements. Integrating new technologies, from robotics to advanced software, can drastically cut labor costs and improve throughput.

Implementing IE for Maximum Cost Savings

Successful implementation of IE strategies requires a systematic approach. Companies should start with a thorough analysis of their current state, identifying key areas for improvement. This often involves data collection, time studies, and employee interviews.

Once opportunities are identified, pilot projects can be launched to test proposed changes on a smaller scale before wider implementation. Continuous monitoring and evaluation are crucial to ensure the changes yield the desired cost reductions and maintain efficiency over time. Furthermore, fostering a culture of continuous improvement, where employees at all levels are encouraged to identify and suggest improvements, is vital.

Comparative Analysis of Cost-Saving Strategies

| Strategy | Primary Benefit | Typical Cost Savings Area |

|---|---|---|

| Process Optimization | Efficiency & Speed | Labor, Time, Rework |

| Waste Reduction (Lean) | Resource Utilization | Inventory, Space, Defects |

| Supply Chain Optimization | Logistics & Inventory | Transportation, Holding Costs |

| Quality Improvement (Six Sigma) | Defect Reduction | Scrap, Warranty, Rework |

| Automation | Scalability & Precision | Labor, Error Rates, Throughput |

Case Studies and Measurable Results

Many organizations across various sectors have successfully leveraged industrial engineering principles for dramatic cost reductions. For instance, a manufacturing firm might reduce product defect rates by 50% using Six Sigma, leading to millions in annual savings. A logistics company could optimize its delivery routes, cutting fuel consumption and vehicle maintenance costs by 15%. Even service industries benefit, with banks streamlining customer service processes to reduce transaction times and improve staff efficiency.

The key is to set clear, measurable objectives before embarking on IE initiatives, such as “reduce processing time by 20%” or “decrease inventory holding costs by 10%.” Regular measurement against these targets ensures that the efforts are truly impacting the bottom line.

The Future of IE in Cost Management

As businesses face increasing pressures from global competition and economic volatility, the role of industrial engineering in Reducing Operational Costs via IE will only grow. The integration of advanced analytics, artificial intelligence, and machine learning will provide even more powerful tools for identifying inefficiencies and predicting outcomes. Digital twins, predictive maintenance, and hyper-automation are emerging trends that will further empower industrial engineers to drive unprecedented levels of operational efficiency and cost control. To explore more about how IE contributes to a company’s overall health, consider reading our article on sustainable business practices.