Digital Twins in Industrial Systems: Revolutionizing Operations

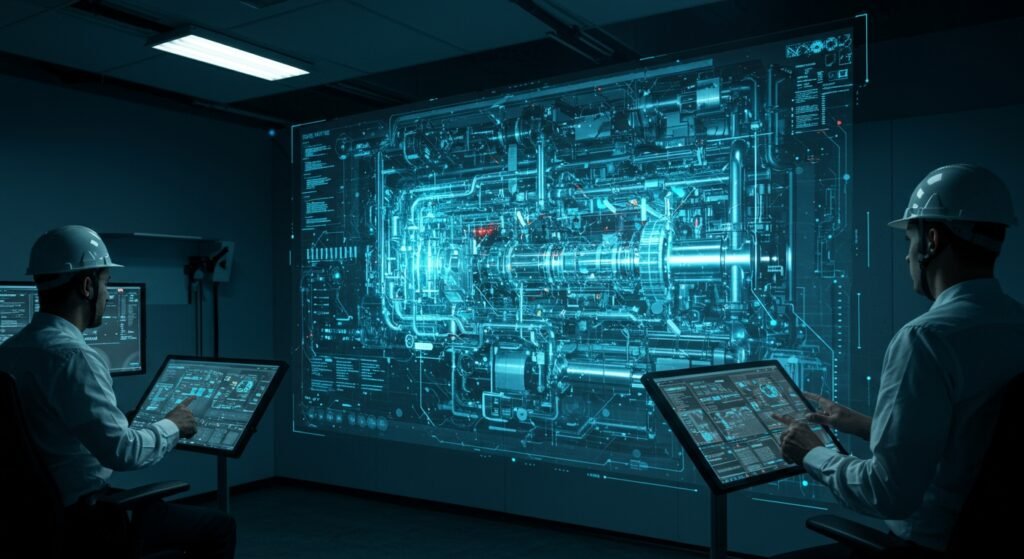

The advent of Digital Twins in Industrial Systems marks a pivotal shift in how industries approach design, operations, and maintenance. By creating virtual replicas of physical assets, processes, or even entire facilities, digital twins offer unparalleled insights and control, paving the way for a new era of efficiency and innovation. This technology is not merely a simulation; it’s a dynamic, real-time digital counterpart that evolves with its physical twin, leveraging data from sensors, IoT devices, and historical records to provide a comprehensive, actionable view.

Table of Contents

- What Are Digital Twins?

- How Digital Twins in Industrial Systems Revolutionize Operations

- Key Benefits of Implementing Digital Twins

- Challenges and Future Outlook

- Conclusion

What Are Digital Twins?

A digital twin is a virtual model designed to accurately reflect a physical object. The object being studied could be a wind turbine, a jet engine, a manufacturing plant, or even a city. The digital twin concept originated at NASA for spacecraft management but has rapidly expanded into various industrial sectors. It functions as a bridge between the physical and digital worlds, allowing for real-time monitoring, analysis, and optimization. This virtual representation is continuously updated with data from its physical counterpart, enabling predictive analysis, performance optimization, and problem diagnosis without needing direct physical interaction.

How Digital Twins in Industrial Systems Revolutionize Operations

The application of digital twin technology across industrial systems brings transformative capabilities. From enhancing operational efficiency to ensuring asset reliability, their impact is far-reaching. Here are some key areas where digital twins are making a significant difference:

Real-time Monitoring and Diagnostics

Digital twins provide operators with real-time visibility into the performance of physical assets. Sensor data streams into the virtual model, allowing for instantaneous analysis of conditions, early detection of anomalies, and rapid diagnosis of issues. This proactive approach minimizes downtime and prevents catastrophic failures.

Predictive Maintenance

Perhaps one of the most compelling applications, digital twins enable highly accurate predictive maintenance. By analyzing historical data and real-time sensor inputs, the twin can forecast potential equipment failures, allowing maintenance to be scheduled precisely when needed, rather than reactively or on a fixed schedule. This optimizes asset lifespan and reduces maintenance costs significantly.

Process Optimization

For complex industrial processes, digital twins can simulate various scenarios to identify the most efficient operating parameters. Engineers can experiment with different configurations, material flows, and production schedules in the virtual environment before implementing changes in the physical world, leading to optimized output, reduced waste, and improved energy efficiency. To learn more about how smart technologies are transforming industries, you can learn more about Industrial IoT.

Product Lifecycle Management

Digital twins support the entire lifecycle of a product, from design and prototyping to manufacturing, operation, and even end-of-life. They facilitate collaborative design, simulate manufacturing processes to identify bottlenecks, and track product performance in the field, feeding valuable insights back into the design cycle for continuous improvement.

Key Benefits of Implementing Digital Twins

Implementing digital twins yields a multitude of benefits for industrial organizations. The technology transforms traditional operational models into data-driven, highly optimized systems. The table below highlights some of the primary advantages:

| Benefit Category | Traditional Approach | Digital Twin Approach |

|---|---|---|

| Operational Efficiency | Reactive problem-solving, manual adjustments | Proactive optimization, AI-driven insights |

| Cost Reduction | High maintenance costs, significant downtime | Reduced maintenance, minimized downtime |

| Risk Management | Limited foresight, higher safety risks | Predictive risk assessment, enhanced safety |

| Innovation & R&D | Physical prototyping, trial-and-error | Virtual testing, rapid iteration |

| Asset Performance | Scheduled maintenance, limited insights | Condition-based maintenance, deep insights |

These benefits contribute to a more resilient, efficient, and competitive industrial landscape. Adhering to standards like those from ISO standards can further enhance data interoperability and system reliability.

Challenges and Future Outlook

While the promise of digital twins is vast, their implementation comes with challenges. These include the significant initial investment in sensors and data infrastructure, the complexity of integrating diverse data sources, and the need for specialized skills to manage and interpret the vast amounts of data generated. Data security and privacy are also paramount concerns.

However, the future of digital twins in industrial systems looks incredibly bright. As IoT technology advances and AI/ML capabilities become more sophisticated, digital twins will grow in accuracy and scope. We can expect to see more comprehensive twins encompassing entire factory ecosystems or even supply chains, leading to hyper-efficient, self-optimizing industrial operations. The ongoing trend towards Industry 5.0, focusing on human-machine collaboration, will likely integrate digital twins even more deeply into the fabric of industrial innovation, making them indispensable for sustainable and intelligent manufacturing.

Conclusion

Digital Twins in Industrial Systems are fundamentally reshaping how industries operate, offering unprecedented opportunities for optimization, efficiency, and innovation. By bridging the gap between the physical and digital worlds, these virtual replicas enable smarter decision-making, predictive capabilities, and a more resilient industrial future. While challenges exist, the undeniable benefits and rapid technological advancements ensure that digital twins will remain at the forefront of the industrial revolution, driving progress and unlocking new levels of performance across the globe.