Strategies for Transitioning to Smart Factories

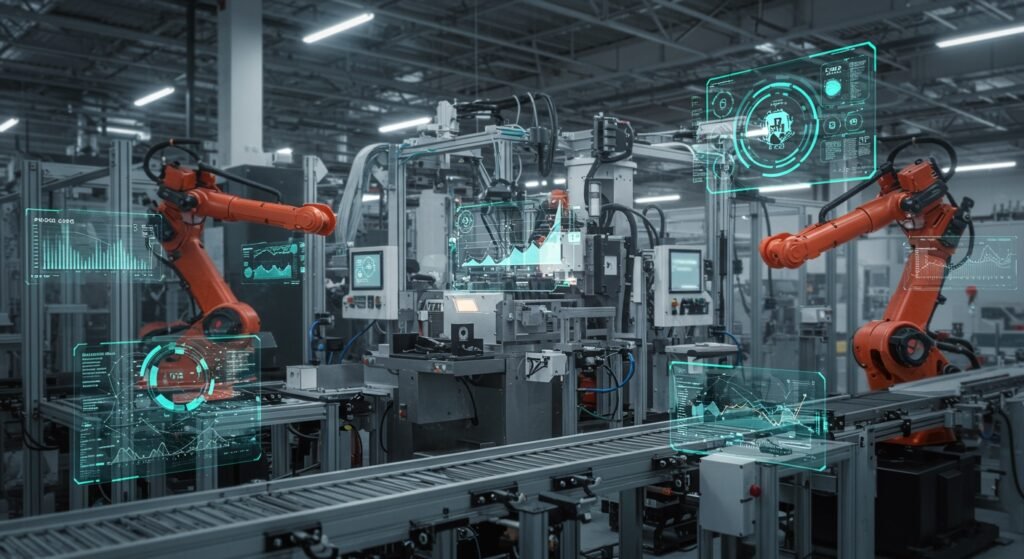

The manufacturing landscape is undergoing a profound transformation, driven by technological advancements that are reshaping production processes and operational efficiencies. At the forefront of this revolution are smart factories, integrated environments where physical and digital systems converge. These intelligent facilities leverage connectivity, data analytics, and automation to create highly responsive, efficient, and sustainable production lines. Embracing the transition to smart factories is no longer an option but a strategic imperative for businesses aiming to maintain competitiveness and foster innovation in the global market. This article outlines key strategies to guide manufacturers through this complex yet rewarding journey, ensuring a successful digital transformation.

Table of Contents

- Understanding the Core Concepts

- Key Strategies for a Smooth Transition

- Overcoming Challenges in Digital Transformation

- The Future of Manufacturing with Smart Factories

- Conclusion

Understanding the Core Concepts

What Are Smart Factories?

A smart factory represents a significant leap from traditional manufacturing plants. It’s a highly digitized and connected production facility that uses advanced technologies like the Internet of Things (IoT), artificial intelligence (AI), machine learning, big data analytics, and robotics to improve efficiency, productivity, and flexibility. In a smart factory, machines, systems, and products communicate and cooperate with each other, creating a self-organizing and adaptive production system. This interconnectedness allows for real-time monitoring, predictive maintenance, and optimized resource allocation, fundamentally changing how goods are produced.

The Pillars of Industry 4.0

The concept of smart factories is intrinsically linked to Industry 4.0, the fourth industrial revolution. Its core pillars include:

- Cyber-Physical Systems (CPS): Integration of computation, networking, and physical processes.

- Internet of Things (IoT): Network of physical objects embedded with sensors, software, and other technologies for connecting and exchanging data.

- Big Data and Analytics: Collection, processing, and analysis of vast datasets to extract insights and improve decision-making.

- Cloud Computing: On-demand availability of computer system resources, especially data storage and computing power, without direct active management by the user.

- Artificial Intelligence (AI) and Machine Learning (ML): Algorithms that enable machines to learn from data and perform tasks that typically require human intelligence.

- Robotics and Automation: Use of robots and automated systems to perform tasks with precision and speed.

Key Strategies for a Smooth Transition

Transitioning to smart factories requires a well-thought-out plan and commitment. Here are some key strategies:

1. Assess Current Infrastructure and Capabilities

Before embarking on digital transformation, conduct a thorough assessment of your existing infrastructure, processes, and technological readiness. Identify gaps, legacy systems, and areas where smart technologies can yield the most significant benefits. This initial phase helps in understanding your starting point and defining realistic goals.

2. Develop a Phased Implementation Roadmap

A successful transition rarely happens overnight. Create a phased roadmap that outlines specific milestones, timelines, and measurable objectives. Start with pilot projects in less critical areas to test technologies and gather insights before scaling up. This iterative approach minimizes risks and allows for continuous learning and adaptation.

3. Invest in the Right Technology: IoT, AI, and Robotics

Strategic investment in core Industry 4.0 technologies is crucial. This includes IoT sensors for data collection, AI/ML platforms for analytics and predictive capabilities, and advanced robotics for automation. Choose solutions that integrate seamlessly with your existing systems and offer scalability. For insights into selecting the right vendors, consider resources like Forbes Technology Council’s guide on choosing vendors.

4. Focus on Workforce Training and Skill Development

Technology alone isn’t enough; your workforce needs to evolve alongside it. Invest in comprehensive training programs to upskill employees in areas like data analytics, AI operations, robotics programming, and cybersecurity. A digitally literate workforce is essential for operating and maintaining smart factory systems effectively. This also addresses potential resistance to change.

5. Prioritize Data Security and Integration

With increased connectivity comes greater vulnerability. Robust cybersecurity measures are paramount to protect sensitive operational data and intellectual property. Implement strong encryption, access controls, and regular security audits. Furthermore, ensure seamless data integration across various platforms and systems to create a unified view of operations, crucial for informed decision-making.

6. Foster a Culture of Innovation

Encourage experimentation, collaboration, and continuous improvement within your organization. A culture that embraces change and values innovation is better equipped to adapt to new technologies and leverage the full potential of smart factories. Empower employees to identify new opportunities for optimization and efficiency gains.

Overcoming Challenges in Digital Transformation

The journey to digital transformation is not without its hurdles. Manufacturers often face:

Financial Investment and ROI

The initial investment in smart factory technologies can be substantial. Demonstrating a clear return on investment (ROI) is crucial for securing stakeholder buy-in. Focus on identifying specific pain points that smart technologies can address, such as reducing downtime, improving product quality, or cutting energy costs. Presenting a strong business case with quantifiable benefits will help.

Technical Complexity and Integration

Integrating diverse technologies and legacy systems can be technically complex. Issues like interoperability, data standardization, and system compatibility often arise. Partnering with experienced technology providers and system integrators can mitigate these challenges, ensuring a smoother transition and more robust system architecture.

Here’s a comparison of traditional vs. smart factory approaches:

| Feature | Traditional Factory | Smart Factory |

|---|---|---|

| Production | Linear, manual, less flexible | Adaptive, automated, highly flexible |

| Data Usage | Limited, siloed, retrospective | Real-time, integrated, predictive analytics |

| Maintenance | Reactive, scheduled | Predictive, proactive |

| Connectivity | Low, isolated systems | High, interconnected via IoT/CPS |

| Decision Making | Human-centric, experience-based | Data-driven, AI-assisted |

| Resource Efficiency | Variable, often suboptimal | Optimized, sustainable |

The Future of Manufacturing with Smart Factories

The widespread adoption of smart factories promises a future of manufacturing characterized by unprecedented efficiency, agility, and innovation. These factories will be able to adapt quickly to market changes, produce highly customized products, and operate with minimal environmental impact. The integration of advanced technologies will lead to safer working conditions, more engaging jobs, and a stronger competitive edge for companies that embrace this transformation. For more insights into the broader impact of this shift, explore our article on the impact of AI on industrial automation.

Conclusion

The transition to smart factories is a complex but essential undertaking for modern manufacturers. By strategically assessing current capabilities, developing a phased roadmap, investing in appropriate technologies, and prioritizing workforce development, businesses can navigate this transformation successfully. Overcoming challenges such as financial investment and technical integration requires foresight and strong partnerships. Ultimately, embracing smart factory principles will not only enhance operational efficiency and productivity but also position organizations at the forefront of the next industrial era, ensuring sustained growth and innovation.