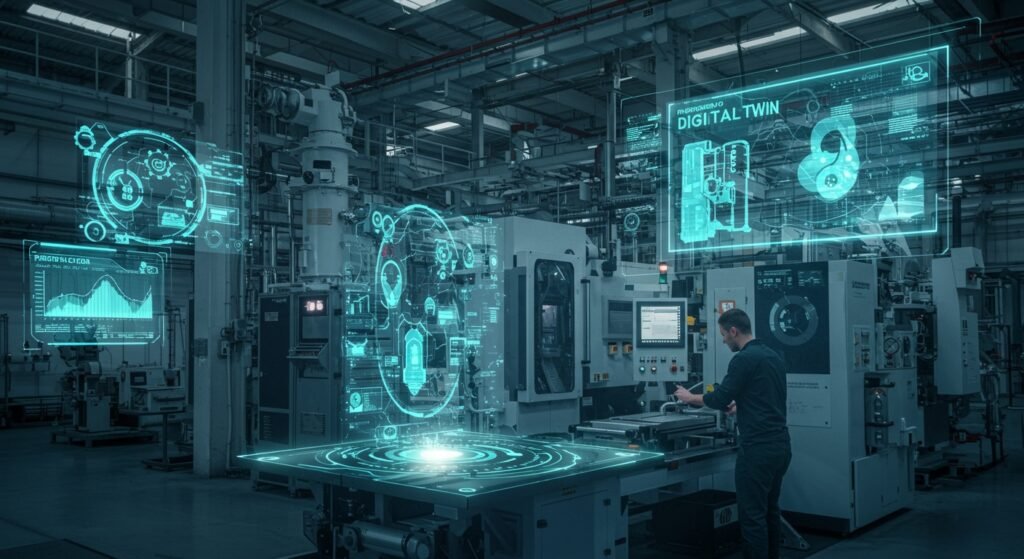

How Digital Twins are Revolutionizing Predictive Maintenance in Manufacturing

The manufacturing industry is constantly seeking innovative ways to enhance efficiency, reduce downtime, and optimize operational costs. Among the most transformative technologies emerging today are digital twins, which are virtual replicas of physical assets, processes, or systems. When integrated with advanced analytics and IoT data, digital twins are not just mirroring reality; they are actively revolutionizing a critical aspect of manufacturing: predictive maintenance.

Table of Contents

- What Are Digital Twins?

- The Evolution of Maintenance: From Reactive to Predictive

- How Digital Twins Enhance Predictive Maintenance

- Key Benefits for Manufacturing

- Challenges and Future Outlook

- Conclusion

What Are Digital Twins?

A digital twin is essentially a virtual model designed to accurately reflect a physical object. This object can be a piece of machinery, an entire production line, or even a whole factory. Through sensors attached to the physical asset, real-time data on its performance, condition, and environment is collected and fed into the digital twin. This continuous flow of information ensures the virtual model remains a precise, up-to-date representation of its real-world counterpart. The power of digital twins lies in their ability to provide insights, simulate scenarios, and predict outcomes without directly interacting with the physical asset.

The Evolution of Maintenance: From Reactive to Predictive

Traditionally, maintenance in manufacturing has been either reactive (fixing things when they break) or preventive (scheduled maintenance at fixed intervals). Both approaches have significant drawbacks. Reactive maintenance leads to costly downtime and unexpected failures. Preventive maintenance, while better, can result in unnecessary maintenance activities on perfectly functional equipment, or conversely, miss impending failures that occur before the scheduled service.

Predictive maintenance emerged as a superior strategy, leveraging data and analytics to anticipate equipment failures before they happen. By monitoring the condition of assets in real-time and analyzing historical data, predictive maintenance allows for timely interventions, minimizing downtime and optimizing resource allocation. However, integrating digital twins takes this a step further.

How Digital Twins Enhance Predictive Maintenance

The synergy between digital twins and predictive maintenance creates a powerful framework for operational excellence in manufacturing. Here’s how:

Real-time Monitoring and Data Integration

Digital twins continuously receive data from sensors embedded in physical equipment. This includes temperature, vibration, pressure, energy consumption, and more. This real-time stream of data allows operators to monitor the exact condition of their assets virtually, identifying anomalies or deviations from normal operating parameters instantly. This granular visibility is crucial for effective predictive analysis.

Advanced Anomaly Detection and Diagnostics

With a comprehensive digital replica, sophisticated algorithms can be applied to the vast datasets. Machine learning models, trained on historical data, can detect subtle patterns that indicate impending failure far more accurately than human observation or simpler rule-based systems. The digital twin can not only flag an issue but also help diagnose its root cause, often before it manifests as a performance degradation in the physical asset.

Simulation and Scenario Planning

One of the most powerful applications of digital twins is their ability to run simulations. Manufacturers can test different operational scenarios, predict the impact of various environmental factors, or evaluate the stress on components under varying loads – all within the virtual environment. This allows for proactive identification of potential failure points and optimization of operational strategies to extend asset lifespan.

Optimized Maintenance Scheduling

By accurately predicting when a component is likely to fail, digital twins enable truly optimized maintenance scheduling. Instead of fixed intervals or emergency repairs, maintenance teams can schedule interventions precisely when they are needed, minimizing unnecessary work and preventing catastrophic failures. This ‘just-in-time’ maintenance approach reduces costs, extends asset life, and increases overall equipment effectiveness (OEE).

Prescriptive Actions and Recommendations

Beyond prediction, advanced digital twins can offer prescriptive advice. Based on detected anomalies and simulations, the system can recommend specific actions to take, such as adjusting operational parameters, ordering specific spare parts, or scheduling a particular type of repair. This transforms predictive maintenance into a proactive, guided process.

Key Benefits for Manufacturing

The integration of digital twins into predictive maintenance offers a multitude of benefits for the manufacturing sector:

- Reduced Downtime: By anticipating failures, companies can schedule maintenance strategically, avoiding unexpected halts in production.

- Cost Savings: Optimized maintenance schedules mean less money spent on unnecessary parts and labor, and significantly reduced costs associated with unplanned downtime.

- Extended Asset Lifespan: Proactive intervention and optimized operation through insights from the digital twin help preserve equipment health and prolong its operational life.

- Enhanced Safety: Identifying potential equipment malfunctions before they become critical reduces risks for workers.

- Improved Product Quality: Maintaining equipment in optimal condition contributes to more consistent and higher-quality product output.

Below is a comparison illustrating the impact:

| Maintenance Type | Downtime | Cost Efficiency | Failure Prediction |

|---|---|---|---|

| Reactive | High (unplanned) | Low | None |

| Preventive | Medium (scheduled) | Medium | Limited |

| Predictive (with Digital Twins) | Low (planned) | High | Highly Accurate |

Challenges and Future Outlook

While the advantages are clear, implementing digital twins for predictive maintenance comes with challenges, including the initial investment in IoT sensors, data infrastructure, and specialized software. Data security and integration complexities also need careful consideration. For more insights on digital transformation in manufacturing, consider exploring our article on Industry 4.0.

However, as technology matures and costs decrease, the adoption of digital twins is set to accelerate. The future holds even more sophisticated applications, including self-optimizing systems where digital twins not only predict but also automatically initiate corrective actions or reconfigure production lines to adapt to changing conditions. The potential for continuous operational improvement is immense, driving manufacturers towards a new era of intelligent, highly efficient operations. For an external perspective on advanced manufacturing, visit NIST’s Advanced Manufacturing Program.

Conclusion

Digital twins represent a monumental leap forward for predictive maintenance in manufacturing. By providing a dynamic, data-rich virtual replica of physical assets, they empower companies to move beyond simply anticipating failures to proactively managing and optimizing their entire operational lifecycle. Manufacturers embracing this technology are not just improving efficiency; they are building more resilient, responsive, and ultimately more profitable operations for the future.