Sustainability and Circular Economy: Best Practices for Industrial Operations

The global industrial landscape is rapidly shifting towards more sustainable models. At the heart of this transformation lies the circular economy, a powerful alternative to the traditional linear “take-make-dispose” approach. For industrial operations, embracing the circular economy is no longer just an environmental concern; it’s a strategic imperative for long-term resilience, innovation, and profitability. This article delves into the core principles and best practices that can help industries transition towards a more sustainable and economically viable future.

Table of Contents

- Understanding the Circular Economy

- Key Principles of Sustainable Industrial Operations

- Best Practices for Transitioning to Circularity

- The Benefits of Adopting a Circular Economy

- Challenges and Solutions

- Conclusion

Understanding the Circular Economy

The traditional industrial model operates on a linear path: extract resources, manufacture products, use them, and then dispose of them. This model, while historically dominant, leads to resource depletion, environmental degradation, and significant waste generation. The circular economy, conversely, aims to keep resources in use for as long as possible, extract the maximum value from them whilst in use, then recover and regenerate products and materials at the end of each service life. It’s about designing out waste and pollution, keeping products and materials in use, and regenerating natural systems.

Linear vs. Circular Models: A Fundamental Shift

The distinction between these two models is crucial for industrial decision-makers. A linear economy sees waste as an unavoidable byproduct, whereas a circular economy views waste as a design flaw and a valuable resource waiting to be reused or repurposed.

Key Principles of Sustainable Industrial Operations

Adopting a circular approach requires a fundamental shift in operational thinking. Here are some guiding principles:

Design for Durability and Recyclability

Manufacturers should design products with longevity and ease of disassembly in mind. This includes selecting durable materials, creating modular components that can be easily repaired or replaced, and ensuring materials can be recycled or composted effectively at their end-of-life.

Optimize Resource Use

This principle focuses on minimizing virgin material input and maximizing the utility of existing resources. Strategies include using recycled content, optimizing manufacturing processes to reduce scrap, and implementing advanced tracking systems to monitor material flows.

Implement Reverse Logistics

Reverse logistics is the process of moving goods from their typical final destination for the purpose of capturing value, or proper disposal. This is critical for closing the loop in a circular economy, enabling product returns, repair, refurbishment, remanufacturing, and recycling.

Best Practices for Transitioning to Circularity

Transitioning to a circular economy model requires strategic planning and execution. Here are practical steps industrial operations can take:

Supply Chain Collaboration

Engage with suppliers and customers to create closed-loop systems. This could involve returning packaging, taking back used products, or sharing resources. Collaboration across the entire value chain is essential for successful circular initiatives.

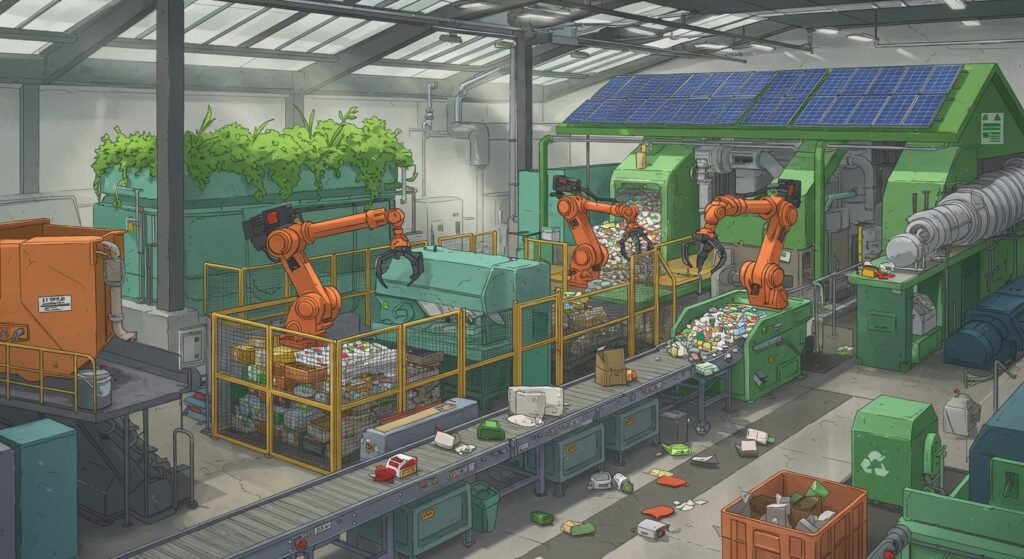

Technology and Innovation

Leverage technologies like IoT for asset tracking, AI for predictive maintenance, and advanced recycling techniques. Innovation in materials science also plays a crucial role in developing bio-based or easily recyclable alternatives.

| Circular Economy Technology | Application in Industry | Benefit |

|---|---|---|

| IoT Sensors | Tracking product lifecycles, optimizing maintenance | Improved resource efficiency, extended product life |

| AI & Machine Learning | Predictive maintenance, waste sorting optimization | Reduced downtime, enhanced recycling rates |

| Advanced Recycling | Chemical recycling of plastics, material recovery | Higher purity recycled materials, reduced landfill |

| Digital Twins | Simulating product design for circularity | Optimized material selection, reduced prototyping costs |

Employee Engagement and Training

A successful transition depends on an informed and engaged workforce. Training employees on circular economy principles, waste sorting, and new operational procedures is vital. Empowering staff to identify opportunities for circularity can drive internal innovation.

The Benefits of Adopting a Circular Economy

The advantages of moving towards a circular model are manifold. Companies can see significant cost savings through reduced material consumption and waste disposal fees. It also enhances brand reputation, attracts environmentally conscious consumers, and fosters innovation. Furthermore, it builds resilience against resource scarcity and price volatility, positioning businesses for long-term sustainability. For more insights on global efforts, consider visiting the European Commission’s Circular Economy initiatives.

Challenges and Solutions

Despite its benefits, implementing a circular economy faces hurdles such as initial investment costs, complex supply chain redesigns, and regulatory barriers. Solutions involve seeking government incentives, fostering cross-industry partnerships, and advocating for supportive policies. Phased implementation and pilot projects can also mitigate risks.

Conclusion

The shift to a circular economy is more than an environmental trend; it’s an economic opportunity that redefines how industrial operations create and deliver value. By adopting principles like design for durability, optimizing resource use, and implementing robust reverse logistics, companies can build more resilient, innovative, and profitable businesses. The journey towards circularity is continuous, but the long-term benefits for both business and the planet are undeniable. For further reading on related topics, explore our article on Sustainable Manufacturing Strategies.