Implementing Industry 5.0: Human-Centric Smart Factories Explained

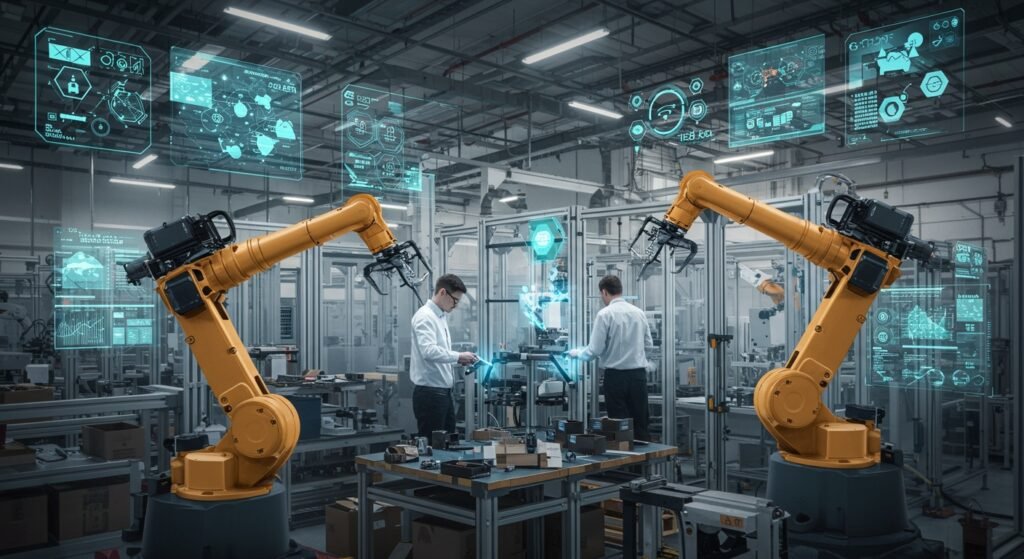

The industrial landscape is constantly evolving, and we are now on the cusp of the next great transformation: Industry 5.0. Moving beyond the automation-focused Industry 4.0, this new paradigm places human well-being and collaboration at the core of smart factories. It’s about combining advanced technology with the unique creativity and critical thinking of humans to create a more resilient, sustainable, and human-centric production system.

Table of Contents

- Understanding Industry 5.0

- Why Embrace Industry 5.0 Now?

- Core Technologies Enabling Industry 5.0

- Challenges and Considerations for Implementation

- A Roadmap to Implementing Industry 5.0

- The Future is Human-Centric

Understanding Industry 5.0: Beyond Automation

While Industry 4.0 revolutionized manufacturing through automation, data exchange, and the Internet of Things (IoT), Industry 5.0 takes this a significant step further. It acknowledges that technology alone is not enough to address complex societal challenges like climate change, resource scarcity, and an aging workforce. Instead, it advocates for a shift where technology serves humanity, enhancing human capabilities rather than replacing them.

Beyond Automation: The Human Element

At its heart, Industry 5.0 emphasizes the importance of human operators, designers, and innovators. It fosters an environment where humans and machines (e.g., collaborative robots or cobots) work together in synergy. This collaboration leverages the strengths of both: machines handle repetitive, dangerous, or high-precision tasks, while humans bring creativity, problem-solving skills, and adaptability to the production process.

Key Pillars of Industry 5.0

- Human-Centricity: Focusing on the well-being and empowerment of workers.

- Sustainability: Developing eco-friendly production processes and reducing waste.

- Resilience: Building robust supply chains and production systems capable of withstanding disruptions.

Why Embrace Industry 5.0 Now?

The benefits of transitioning to Industry 5.0 extend beyond the factory floor, impacting businesses, employees, and society at large.

Benefits for Businesses

Companies adopting Industry 5.0 principles can achieve higher efficiency, better quality control, and increased innovation. By integrating human expertise with smart automation, businesses can adapt more quickly to market demands, develop customized products, and create more flexible production lines. This approach also leads to a more engaged and motivated workforce, reducing turnover and increasing productivity.

Benefits for Workers

For employees, Industry 5.0 means a safer, more stimulating work environment. Repetitive and dangerous tasks are minimized, allowing workers to focus on more creative, decision-making, and value-added activities. It promotes skill development, lifelong learning, and a sense of purpose, contributing to overall job satisfaction and well-being.

Core Technologies Enabling Industry 5.0

Several advanced technologies are crucial for the successful implementation of Industry 5.0.

Collaborative Robots (Cobots)

Cobots are designed to work safely alongside humans, assisting with tasks like assembly, material handling, and quality inspection. Their ability to learn and adapt makes them invaluable partners in a human-centric factory.

Advanced AI and Machine Learning

AI algorithms can analyze vast amounts of data to optimize production, predict maintenance needs, and personalize human-machine interfaces, making interactions more intuitive and efficient.

IoT and Digital Twins

The Internet of Things connects devices and sensors, gathering real-time data from the factory floor. Digital twins create virtual replicas of physical assets, allowing for simulation, analysis, and optimization of processes without disrupting actual production.

Challenges and Considerations for Implementation

While the vision of Industry 5.0 is compelling, its implementation comes with certain challenges.

Upskilling and Reskilling the Workforce

A significant effort is required to train existing employees with new digital and collaborative skills to work effectively with advanced technologies. This includes training in data analytics, AI interpretation, and human-robot interaction.

Data Security and Privacy

As factories become more connected, ensuring the security and privacy of sensitive production data becomes paramount. Robust cybersecurity measures are essential to prevent breaches and protect intellectual property.

Investment and ROI

The initial investment in new technologies and training can be substantial. Businesses need to carefully plan their transition, demonstrating clear returns on investment through increased efficiency, innovation, and improved worker satisfaction.

A Roadmap to Implementing Industry 5.0

A structured approach is essential for a smooth transition to Industry 5.0. Here’s a simplified roadmap:

| Step | Description | Key Actions |

|---|---|---|

| 1. Assess Current State | Understand existing processes, technologies, and workforce capabilities. | Conduct audits, identify bottlenecks. |

| 2. Define Vision & Goals | Clearly articulate what human-centric smart factory means for your organization. | Set measurable objectives for sustainability, resilience, and human well-being. |

| 3. Technology Adoption | Select and integrate appropriate Industry 5.0 technologies. | Pilot cobots, AI systems, IoT sensors. |

| 4. Workforce Development | Invest in training and reskilling programs for employees. | Develop curricula for digital literacy, human-robot collaboration. |

| 5. Cultural Shift | Foster a culture of collaboration, innovation, and continuous learning. | Promote cross-functional teams, open communication. |

| 6. Pilot & Scale | Start with small-scale pilot projects and gradually expand. | Iterate, gather feedback, optimize before full deployment. |

| 7. Monitor & Adapt | Continuously monitor performance, worker satisfaction, and environmental impact. | Adjust strategies based on outcomes and evolving needs. |

The Future is Human-Centric

The shift towards Industry 5.0 is not merely an upgrade in technology; it’s a fundamental re-evaluation of how industry can serve humanity and the planet. By prioritizing human-centric design, sustainability, and resilience, smart factories will become places where innovation flourishes, workers thrive, and production is optimized for the greater good.

For more insights into the European Union’s perspective on this transformation, you can refer to the European Commission’s official Industry 5.0 publications. If you’re interested in related topics, explore our article on Sustainable Manufacturing Practices.