How Machine Learning Transforms Predictive Maintenance Strategies

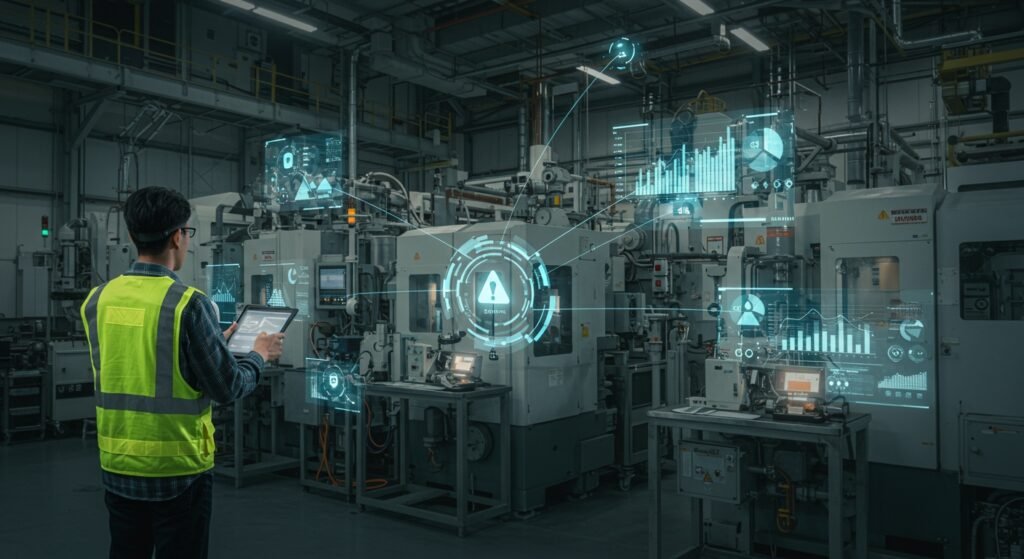

In the complex world of industrial operations, maintaining machinery and equipment is paramount. Traditional maintenance approaches often lead to unexpected downtimes or unnecessary scheduled interventions, incurring significant costs and productivity losses. However, the advent of machine learning is revolutionizing this landscape, transforming predictive maintenance strategies from reactive guesswork into proactive, data-driven foresight. By analyzing vast amounts of operational data, machine learning algorithms can anticipate equipment failures long before they occur, enabling businesses to optimize their maintenance schedules, reduce costs, and enhance overall operational efficiency.

Table of Contents

- The Evolution of Maintenance: From Reactive to Predictive

- How Machine Learning Powers Predictive Maintenance

- Key Benefits of Integrating Machine Learning

- Implementing Machine Learning in Your Strategy

- Challenges and Future Outlook

- Conclusion

The Evolution of Maintenance: From Reactive to Predictive

Maintenance strategies have evolved significantly over the decades, driven by technological advancements and the increasing demand for efficiency and reliability in industrial settings.

Reactive vs. Preventive Maintenance

Historically, organizations relied on reactive maintenance, fixing equipment only after a breakdown occurred. This ‘run-to-failure’ approach often resulted in costly emergency repairs, extensive downtime, and potential safety hazards. The next step was preventive maintenance, which involved scheduled inspections and servicing based on time or usage intervals. While better than reactive, it often led to unnecessary component replacements or missed early signs of failure, as maintenance was not tied to actual equipment condition.

The Rise of Predictive Maintenance

Predictive maintenance emerged as a smarter alternative, focusing on monitoring the actual condition of assets to predict when a failure might occur. This allows for maintenance to be performed only when needed, just before a potential breakdown. Early forms relied on statistical analysis and basic condition monitoring techniques, but the true power of predictive maintenance has been unleashed with the integration of advanced analytics and, most notably, machine learning.

How Machine Learning Powers Predictive Maintenance

Machine learning brings unprecedented capabilities to predictive maintenance by enabling systems to learn from historical and real-time data. Sensor data (vibration, temperature, pressure, current, acoustic), operational logs, maintenance records, and even environmental data are fed into sophisticated algorithms. These algorithms identify subtle patterns and correlations that human operators or simpler analytical tools might miss, indicating impending failures.

Data Collection and Feature Engineering

The foundation of any machine learning model is high-quality data. Industrial sensors collect vast amounts of data points from critical equipment. Feature engineering then transforms this raw data into meaningful features that machine learning models can understand, such as statistical aggregates (mean, variance), frequency domain features, or trend indicators.

Model Training and Anomaly Detection

Machine learning models are trained on historical data sets containing both normal operation and known failure modes. This training allows them to establish a ‘baseline’ of healthy behavior. When new, real-time data deviates significantly from this baseline, the model flags it as an anomaly, indicating a potential issue. Different algorithms, from traditional statistical models to deep neural networks, are employed depending on the complexity and volume of the data.

Common Machine Learning Techniques in Predictive Maintenance

| Technique | Description | Application |

|---|---|---|

| Regression | Predicts continuous values like remaining useful life (RUL). | Estimating equipment lifespan, determining optimal replacement times. |

| Classification | Categorizes equipment status (e.g., ‘healthy’, ‘at risk’, ‘failed’). | Failure mode detection, classifying severity of issues. |

| Clustering | Groups similar data points to identify normal vs. abnormal patterns. | Anomaly detection, identifying unknown or novel failure modes. |

| Deep Learning | Uses neural networks for complex pattern recognition in large datasets. | Processing raw sensor signals (e.g., vibration, sound waves) for intricate defect detection. |

| Time Series Forecasting | Predicts future values based on historical time-stamped data. | Forecasting equipment load, predicting future sensor readings, remaining useful life. |

Key Benefits of Integrating Machine Learning

The strategic implementation of machine learning in predictive maintenance yields numerous significant advantages for businesses.

Reducing Downtime and Costs

By accurately predicting failures, organizations can schedule maintenance during planned downtime or low-production periods, avoiding costly emergency shutdowns and overtime labor. This proactive approach significantly lowers overall maintenance expenditures and prevents revenue loss from unexpected operational halts. For deeper insights into the broader impact of industrial AI, explore resources like IBM’s Industrial AI perspectives.

Extending Asset Lifespan

Precisely timed maintenance, based on actual wear and tear rather than arbitrary schedules, ensures that components are replaced or serviced only when necessary. This prevents premature replacements and prolongs the operational life of expensive assets, maximizing return on investment.

Enhancing Safety and Reliability

Predicting equipment failure reduces the risk of catastrophic breakdowns, which can pose significant safety risks to personnel. More reliable machinery also contributes to a more stable production environment, reducing variability and improving product quality.

Optimizing Resource Allocation

With clear insights into future maintenance needs, companies can optimize inventory management for spare parts, ensuring necessary components are available without excessive stocking. Maintenance teams can also be deployed more efficiently, focusing on critical tasks identified by the system.

Implementing Machine Learning in Your Strategy

Adopting machine learning for predictive maintenance requires careful planning and execution.

Data Acquisition and Preparation

The first step is establishing robust data collection infrastructure, often through Industrial IoT (IIoT) sensors. Data must then be cleaned, transformed, and aggregated to be suitable for machine learning models. Understanding the role of sensors and data acquisition is crucial, which ties into the broader concept of Industrial IoT.

Choosing the Right Algorithms

Selecting appropriate machine learning algorithms depends on the type of data, the specific failure modes, and the desired outcome (e.g., classification of fault types, regression for RUL). This often involves experimentation and validation.

Continuous Monitoring and Improvement

Machine learning models are not static; they need continuous monitoring and retraining as new data becomes available or operational conditions change. Performance metrics must be tracked, and models updated to maintain accuracy and relevance.

Challenges and Future Outlook

While the benefits are clear, implementing machine learning in predictive maintenance also presents challenges, including data quality issues, the need for specialized expertise, and integration with legacy systems. However, ongoing advancements in edge AI, cloud computing, and more accessible ML platforms are rapidly addressing these hurdles.

The future of predictive maintenance with machine learning looks promising, moving towards more prescriptive maintenance where not only are failures predicted, but optimal actions are recommended, often automated. Integration with digital twins and advanced robotics will further enhance the precision and efficiency of industrial asset management.

Conclusion

The transformation of predictive maintenance by machine learning is no longer a futuristic concept but a present-day reality for leading industrial organizations. By leveraging the power of data analytics, companies can move beyond reactive fixes and scheduled guesswork to a truly intelligent, proactive approach to asset management. This shift not only reduces operational costs and minimizes downtime but also significantly enhances safety, reliability, and overall business competitiveness. Embracing machine learning is a strategic imperative for any enterprise looking to thrive in the Industry 4.0 era.