Predictive Maintenance in Energy and Utility Industries

The energy and utility sectors are undergoing a profound transformation, driven by the increasing demand for reliable, efficient, and sustainable operations. In this dynamic landscape, the adoption of predictive maintenance energy strategies has emerged as a game-changer. Moving beyond traditional reactive and preventive approaches, predictive maintenance leverages advanced analytics and real-time data to anticipate equipment failures before they occur, promising unparalleled operational efficiency and cost savings for critical infrastructure.

Table of Contents

- What is Predictive Maintenance and Why is it Crucial for Predictive Maintenance Energy?

- Key Technologies Driving Predictive Maintenance in Energy

- Benefits of Implementing Predictive Maintenance in Utilities

- Challenges and Solutions in PM Adoption

- Real-World Applications and Success Stories

- The Future of Predictive Maintenance in Energy

- Conclusion

What is Predictive Maintenance and Why is it Crucial for Predictive Maintenance Energy?

Predictive maintenance (PdM) is a condition-based maintenance strategy that monitors the actual condition of assets to predict when maintenance should be performed. Unlike reactive maintenance (fixing things after they break) or preventive maintenance (fixing things on a fixed schedule), PdM uses data analysis techniques to detect anomalies, identify patterns, and forecast equipment degradation. For the vast and complex infrastructure of energy and utility companies – including power plants, transmission lines, transformers, wind turbines, and smart grid components – this proactive approach is not just beneficial, but essential. It ensures uninterrupted service, minimizes downtime, and extends asset lifespan, making predictive maintenance energy a cornerstone of modern utility operations.

Shifting from Reactive to Proactive

Historically, utilities often operated on a ‘run-to-fail’ or time-based maintenance model. While straightforward, these methods are inefficient and costly. Reactive maintenance leads to unexpected outages and expensive emergency repairs, while time-based preventive maintenance can result in unnecessary servicing of healthy equipment. Predictive maintenance, however, offers the precision to maintain assets only when needed, based on their actual condition, thereby optimizing resource allocation and significantly reducing operational expenditures.

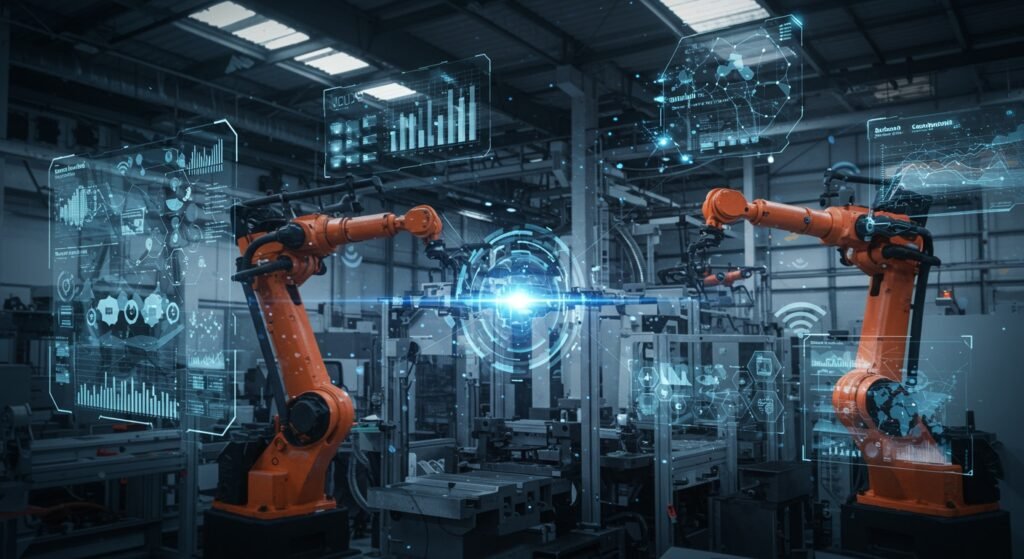

Key Technologies Driving Predictive Maintenance in Energy

The success of predictive maintenance hinges on a suite of advanced technologies working in concert.

IoT Sensors and Data Collection

At the heart of PdM are Internet of Things (IoT) sensors. These devices are embedded in critical equipment – from gas pipelines to solar panels and substations – collecting real-time data on parameters such as vibration, temperature, pressure, current, voltage, and acoustics. This continuous stream of data provides the raw material for predictive models, enabling a comprehensive view of asset health.

AI and Machine Learning for Anomaly Detection

The sheer volume of data collected by IoT sensors would be overwhelming without artificial intelligence (AI) and machine learning (ML) algorithms. These powerful tools analyze patterns, detect subtle anomalies that might indicate impending failure, and build predictive models. ML algorithms can learn from historical data to identify early warning signs, reducing false positives and improving the accuracy of maintenance predictions. This capability is vital for managing the complex interplay of systems in energy infrastructure.

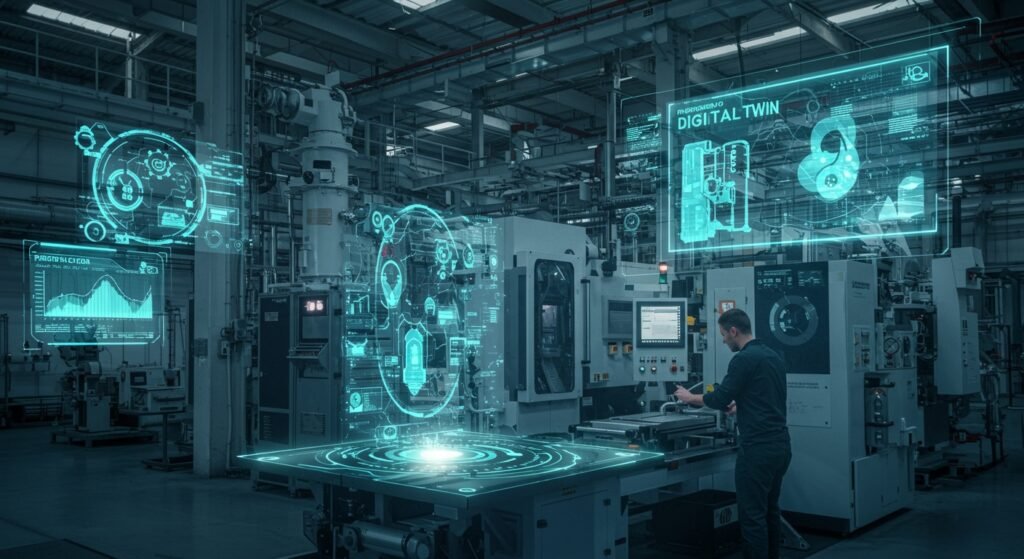

Digital Twins and Simulation

Digital twins are virtual replicas of physical assets, processes, or systems. By continuously updating these digital models with real-time sensor data, utilities can simulate various scenarios, test maintenance strategies, and predict the behavior of their equipment under different conditions. This provides a powerful platform for understanding asset performance and optimizing maintenance schedules without risking physical assets.

Benefits of Implementing Predictive Maintenance in Utilities

Implementing a robust predictive maintenance energy strategy delivers a multitude of benefits across the energy and utility value chain.

Enhanced Reliability and Uptime

By anticipating failures, utilities can schedule maintenance proactively, minimizing unplanned downtime and ensuring a consistent supply of energy. This directly translates to increased operational reliability and customer satisfaction, crucial for maintaining public trust and meeting regulatory obligations.

Optimized Maintenance Costs

Predictive maintenance significantly reduces maintenance costs by eliminating unnecessary routine servicing and preventing catastrophic failures that lead to expensive repairs or replacements. It optimizes inventory management by ensuring parts are ordered only when needed, reducing storage costs and waste.

Improved Safety and Environmental Compliance

Fewer unexpected equipment failures mean a safer working environment for technicians and reduced risks of incidents like power surges or environmental hazards. Additionally, optimized asset performance contributes to energy efficiency and a smaller carbon footprint, supporting environmental compliance goals.

Challenges and Solutions in PM Adoption

While the benefits are clear, adopting predictive maintenance isn’t without its hurdles. Here’s a look at common challenges and their corresponding solutions:

| Challenge | Solution |

|---|---|

| Data Integration Complexity | Implement robust data integration platforms and standardized protocols to consolidate data from disparate sources. |

| Lack of Skilled Personnel | Invest in training programs for existing staff, hire data scientists and AI specialists, or partner with expert third-party providers. |

| Initial Investment Cost | Start with pilot projects on critical assets to demonstrate ROI, secure funding, and scale gradually. |

| Cybersecurity Concerns | Implement strong cybersecurity measures, including encryption, access controls, and continuous monitoring for IoT devices and data platforms. |

| Resistance to Change | Foster a culture of innovation, communicate the benefits clearly, and involve employees in the transition process. |

Real-World Applications and Success Stories

From smart grids to renewable energy farms, predictive maintenance energy solutions are already proving their worth. In offshore wind farms, for instance, PdM systems monitor turbine health, predicting component failures and scheduling maintenance only when conditions are favorable, thereby reducing costly trips and maximizing energy generation. Similarly, in traditional power generation, advanced sensors and analytics prevent unplanned outages in thermal plants by detecting nascent issues in boilers, turbines, and generators. To learn more about how asset management strategies can be integrated, you can read our Asset Management Strategies article.

The Future of Predictive Maintenance in Energy

The trajectory for predictive maintenance in the energy sector is one of continuous innovation and expansion. We can expect increasingly sophisticated AI models, deeper integration with enterprise resource planning (ERP) systems, and the proliferation of autonomous maintenance robots. The drive towards decarbonization and the expansion of renewable energy sources will further amplify the need for highly efficient and reliable asset management, placing predictive maintenance at the forefront of operational excellence. For further insights into industry standards and best practices, consider visiting relevant industry bodies like the U.S. Energy Information Administration.

Conclusion

Predictive maintenance is no longer a luxury but a necessity for energy and utility companies striving for efficiency, reliability, and sustainability. By harnessing the power of data, AI, and IoT, the sector can move towards a future where equipment failures are rare, operational costs are optimized, and energy supply is more stable than ever. Embracing predictive maintenance energy is key to navigating the complexities of the modern energy landscape and securing a resilient future.