Predictive Maintenance for Medical Equipment and Hospital Assets

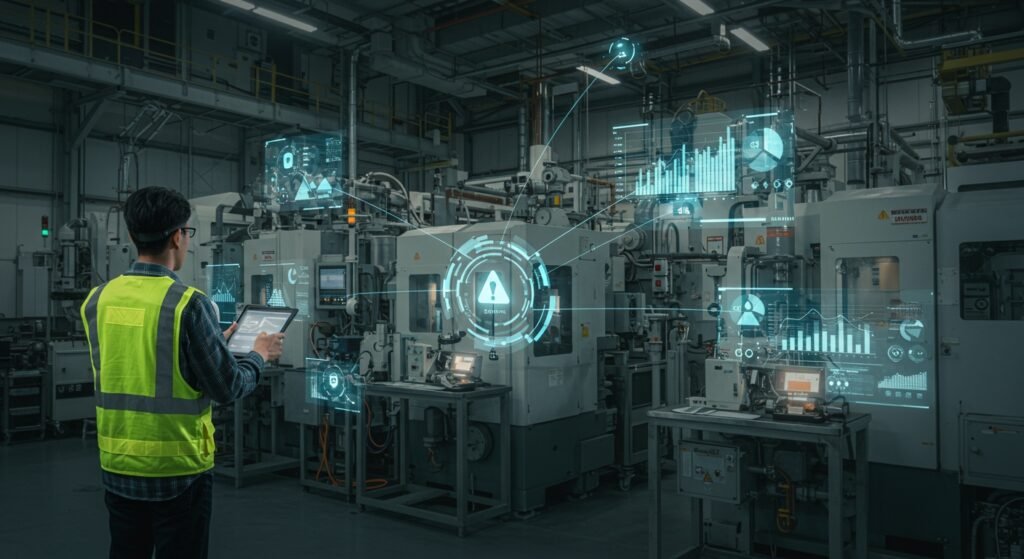

In the high-stakes environment of healthcare, reliable medical equipment is not just a convenience; it’s a critical component of patient safety and operational efficiency. The traditional reactive or time-based maintenance approaches often fall short, leading to unexpected failures, costly repairs, and potential risks to patient care. This is where **predictive maintenance** emerges as a game-changer, offering a sophisticated solution to anticipate and prevent equipment breakdowns before they occur. By leveraging data analytics and advanced technologies, hospitals can optimize the performance and longevity of their vital assets, ensuring uninterrupted service and superior patient outcomes.

Table of Contents

- What is Predictive Maintenance and Why is it Crucial for Healthcare?

- Key Benefits of Predictive Maintenance in Hospitals

- Technologies Driving Predictive Maintenance

- Implementing Predictive Maintenance: A Step-by-Step Guide

- Conclusion

What is Predictive Maintenance and Why is it Crucial for Healthcare?

**Predictive maintenance** (PdM) is a maintenance strategy that uses data analysis techniques to detect anomalies in equipment operation and predict when a piece of equipment might fail. Unlike preventive maintenance, which performs tasks at fixed intervals, PdM monitors the actual condition of equipment to determine when maintenance is truly needed. This data-driven approach allows healthcare facilities to move beyond scheduled overhauls, which can be unnecessary or too late, to a more efficient and effective system.

In a hospital, the failure of critical equipment like MRI machines, ventilators, or surgical robots can have devastating consequences. Not only does it disrupt operations and lead to cancelled procedures, but it can also compromise patient safety. PdM helps to mitigate these risks by providing early warnings of potential issues, enabling maintenance teams to intervene proactively.

Shifting from Reactive to Proactive

Traditionally, many hospitals operate on a reactive maintenance model, fixing equipment only after it breaks down. This often leads to emergency repairs, higher costs, and unpredictable downtime. Predictive maintenance shifts this paradigm entirely. By continuously monitoring equipment health, maintenance can be scheduled precisely when needed, minimizing disruptions and extending asset life. This proactive stance ensures that medical devices are always in optimal working condition, ready to support patient care.

Key Benefits of Predictive Maintenance in Hospitals

The advantages of implementing predictive maintenance in a healthcare setting are numerous and impactful.

Enhanced Equipment Reliability

By constantly monitoring key performance indicators and identifying subtle changes that indicate impending failure, PdM significantly boosts the reliability of medical equipment. This means fewer unexpected breakdowns and more consistent availability of crucial devices, directly supporting continuous patient care services.

Reduced Downtime and Improved Patient Care

Unscheduled downtime can severely impact hospital operations, leading to delays in diagnosis and treatment. Predictive maintenance helps minimize this by allowing maintenance to be planned during off-peak hours or when equipment is not in use, thereby ensuring that patient care is not interrupted. A seamless operation means better patient flow and higher quality of care.

Significant Cost Savings

Reactive maintenance is notoriously expensive due to emergency repairs, expedited parts shipping, and overtime labor. PdM reduces these costs by preventing catastrophic failures, optimizing parts inventory, and extending the lifespan of assets. It also minimizes the need for routine, potentially unnecessary, preventive maintenance tasks, saving both time and resources. Consider the following comparison:

| Maintenance Type | Key Characteristics | Cost Implications |

|---|---|---|

| Reactive | Repair after failure, unplanned | High, includes emergency repairs, lost revenue |

| Preventive | Time-based, scheduled, often unnecessary | Moderate, planned downtime, parts replacement |

| Predictive | Condition-based, data-driven, optimized timing | Low to Moderate, maximized asset life, reduced breakdowns |

Technologies Driving Predictive Maintenance

The backbone of effective predictive maintenance lies in the sophisticated technologies that enable data collection, analysis, and actionable insights.

IoT Sensors and Data Collection

Modern medical equipment can be outfitted with Internet of Things (IoT) sensors that continuously collect data on various parameters such as temperature, vibration, pressure, power consumption, and operational cycles. This real-time data provides a comprehensive picture of the equipment’s health and performance.

AI and Machine Learning for Anomaly Detection

Once data is collected, Artificial Intelligence (AI) and Machine Learning (ML) algorithms analyze it to identify patterns, detect anomalies, and predict potential failures. These algorithms can learn from historical data to recognize what constitutes normal operation and flag deviations that indicate an impending issue, often before human technicians would notice.

Implementing Predictive Maintenance: A Step-by-Step Guide

Adopting a predictive maintenance strategy requires careful planning and execution:

- Assess Current Assets: Identify critical equipment and their current maintenance schedules.

- Choose Technology: Select appropriate IoT sensors, data analytics platforms, and AI/ML tools.

- Integrate Data: Connect sensors to a central system for real-time data collection and analysis.

- Develop Models: Train AI/ML models using historical and real-time data to predict failures.

- Train Staff: Educate maintenance personnel on new technologies and processes.

- Start Small: Begin with a pilot program on a few critical assets before scaling up.

- Monitor and Optimize: Continuously evaluate the system’s effectiveness and make adjustments.

For more insights into managing hospital assets effectively, explore our guide on Hospital Asset Management Strategies.

Implementing a robust predictive maintenance program can be complex, and collaborating with experts or referring to industry standards, such as those provided by organizations like The World Health Organization, can provide valuable guidance and ensure best practices are followed.

Conclusion

Predictive maintenance is transforming how healthcare facilities manage their valuable medical equipment and hospital assets. By moving from reactive fixes to proactive, data-driven interventions, hospitals can ensure higher equipment uptime, enhance patient safety, and achieve significant operational cost savings. Embracing this advanced maintenance strategy is not just about fixing machines; it’s about building a more resilient, efficient, and patient-centric healthcare system for the future.