Agile Practices in Industrial Projects: Revolutionizing Efficiency

The landscape of industrial projects is undergoing a significant transformation, driven by the increasing need for adaptability, speed, and efficiency. In this dynamic environment, the adoption of Agile Practices in Industrial Projects is no longer a niche concept but a strategic imperative. Traditionally, industrial projects have relied on rigid, linear methodologies, but the complexities of modern engineering and manufacturing demand a more flexible approach. This article explores how agile principles are being successfully integrated into industrial settings, offering a roadmap for project managers and engineers looking to enhance productivity and innovation.

Table of Contents

- Understanding Agile in an Industrial Context

- Key Agile Practices for Industrial Projects

- Benefits and Challenges of Implementing Agile

- Overcoming Hurdles and Best Practices

- The Future of Industrial Engineering with Agile

- Conclusion

Understanding Agile in an Industrial Context

Agile, originating in software development, emphasizes iterative development, collaboration, and rapid response to change. Applying these principles to physical products, complex supply chains, and large-scale infrastructure projects requires a nuanced understanding. It’s not about abandoning structure entirely, but rather embedding flexibility within a structured framework. The focus shifts from upfront comprehensive planning to adaptive planning, continuous improvement, and early delivery of value.

Core Principles and Their Industrial Application

At its heart, agile encourages frequent inspection and adaptation. For industrial engineering, this translates into breaking down large projects into smaller, manageable ‘sprints’ or ‘iterations’. Each iteration delivers a functional increment or a refined component, allowing stakeholders to provide feedback early and often. This approach significantly reduces the risk of large-scale failures and ensures that the final product aligns closely with evolving market demands and technical specifications. It’s about ‘build a little, test a little, learn a lot’.

Key Agile Practices for Industrial Projects

Several core agile practices can be effectively adapted for industrial projects:

Iterative Development and Sprints

Instead of a single, long development cycle, projects are divided into short, fixed-length iterations (e.g., 2-4 weeks). Each sprint aims to complete specific, tangible deliverables. For instance, in developing a new machine, one sprint might focus on designing and prototyping a specific module, while the next focuses on its integration and testing. This allows for continuous validation and course correction.

Cross-Functional Teams and Collaboration

Agile promotes small, self-organizing teams comprising individuals with diverse skills – mechanical engineers, electrical engineers, software developers, quality assurance, and even end-users. This co-location and intense collaboration break down silos, accelerate decision-making, and foster a shared sense of ownership. Daily stand-up meetings keep everyone informed and facilitate quick problem-solving.

Continuous Feedback and Adaptation

Regular reviews with stakeholders ensure that the project remains aligned with requirements. Feedback is actively sought and incorporated into subsequent iterations, making the project highly responsive to changes in technology, market conditions, or regulatory requirements. This continuous loop of feedback, learning, and adaptation is crucial for complex industrial ventures.

Benefits and Challenges of Implementing Agile

Implementing Agile Practices in Industrial Projects can yield substantial benefits, including faster time-to-market, improved product quality, enhanced team morale, and greater customer satisfaction. However, it also presents unique challenges, such as integrating agile with existing safety regulations, managing physical prototypes, and cultural resistance to change within traditional organizations.

| Feature | Traditional (Waterfall) | Agile |

|---|---|---|

| Planning | Detailed upfront planning | Adaptive, iterative planning |

| Flexibility | Low; resistant to change | High; embraces change |

| Feedback Loop | Late in the cycle | Continuous and early |

| Deliverables | Large, single delivery | Small, incremental deliveries |

| Risk Management | Attempt to foresee all risks | Identifies and mitigates risks iteratively |

Overcoming Hurdles and Best Practices

To successfully adopt agile, industrial organizations must focus on strong leadership support, investing in training, and fostering a culture of psychological safety where experimentation and learning from failures are encouraged. Starting with smaller, less critical projects can serve as a pilot. For more insights into project management best practices, explore our guide on effective project management strategies.

Furthermore, leveraging digital tools for project tracking, communication, and simulation can greatly enhance agile workflows in industrial settings. Understanding the nuances of physical production requires a blend of digital and traditional methods, creating a hybrid agile approach. For deeper dives into agile transformation, consider resources like the Agile Alliance.

The Future of Industrial Engineering with Agile

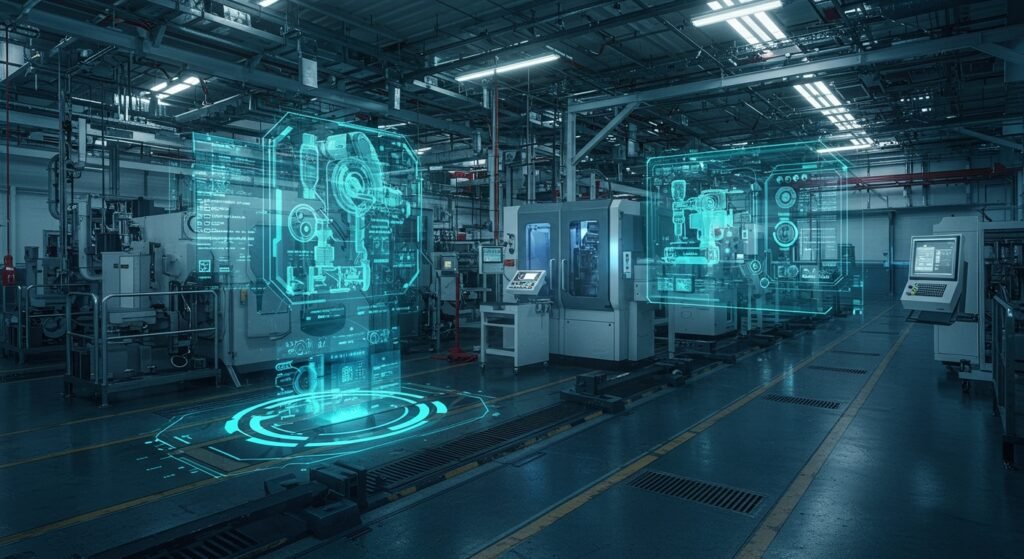

The trends towards Industry 4.0, smart manufacturing, and increased customization mean that the demand for agility will only grow. Industrial engineering is evolving, and agile methodologies are key to navigating this future. Companies that successfully integrate agile will be better positioned to innovate rapidly, respond to disruptions, and maintain a competitive edge in a globalized marketplace. This includes adopting new technologies faster and optimizing complex operational processes.

Conclusion

The integration of Agile Practices in Industrial Projects represents a paradigm shift that promises to unlock new levels of efficiency, innovation, and responsiveness. While the journey may present its challenges, the benefits of embracing iterative development, cross-functional collaboration, and continuous feedback are undeniable. By strategically adapting agile principles to their unique contexts, industrial organizations can not only survive but thrive in the rapidly evolving industrial landscape, ultimately delivering greater value to their customers and stakeholders.