7 Proven Strategies for a Successful Transition to Smart Factories

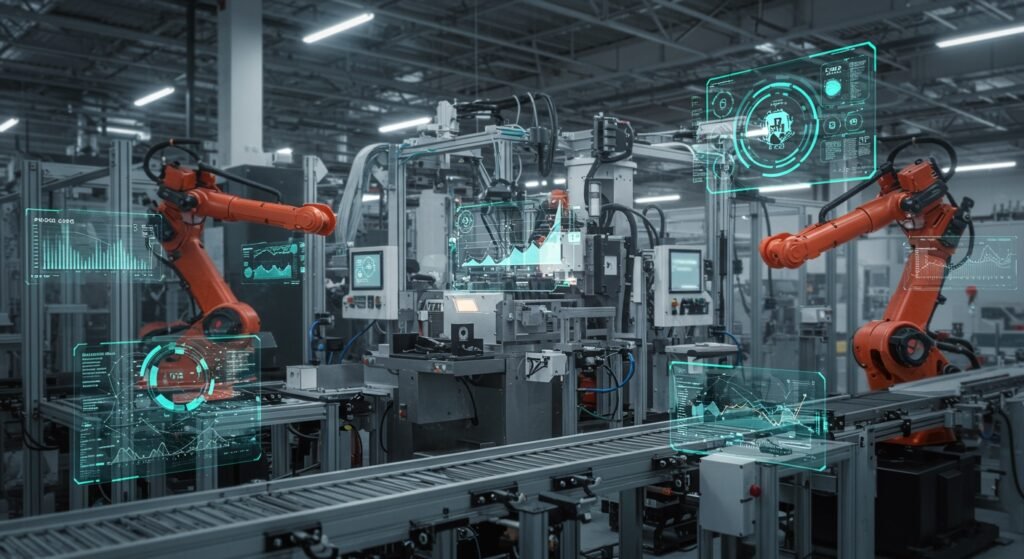

Strategies for Transitioning to Smart Factories The manufacturing landscape is undergoing a profound transformation, driven by technological advancements that are reshaping production processes and operational efficiencies. At the forefront of this revolution are smart factories, integrated environments where physical and digital systems converge. These intelligent facilities leverage connectivity, data analytics, and automation to create highly […]

7 Proven Strategies for a Successful Transition to Smart Factories Read More »