In the rapidly evolving landscape of modern manufacturing, the debate between traditional automation in industry and the newer wave of collaborative robots (cobots) is central to achieving significant productivity gains. Businesses worldwide are scrutinizing which path offers the most sustainable and scalable advantages as we look towards 2025. This article delves into both approaches, comparing their strengths, weaknesses, and potential for synergy, helping you navigate the complexities of industrial evolution.

Table of Contents

- Understanding Automation in Industry: The Traditional Approach

- Pros and Cons of Traditional Industrial Automation

- The Rise of Cobots: Collaboration Redefined

- Advantages and Limitations of Collaborative Robots

- Automation in Industry vs. Cobots: A Comparative Analysis

- Strategic Implementation for Maximum Productivity Gains

- Future Outlook: Synergies and Evolution

Understanding Automation in Industry: The Traditional Approach

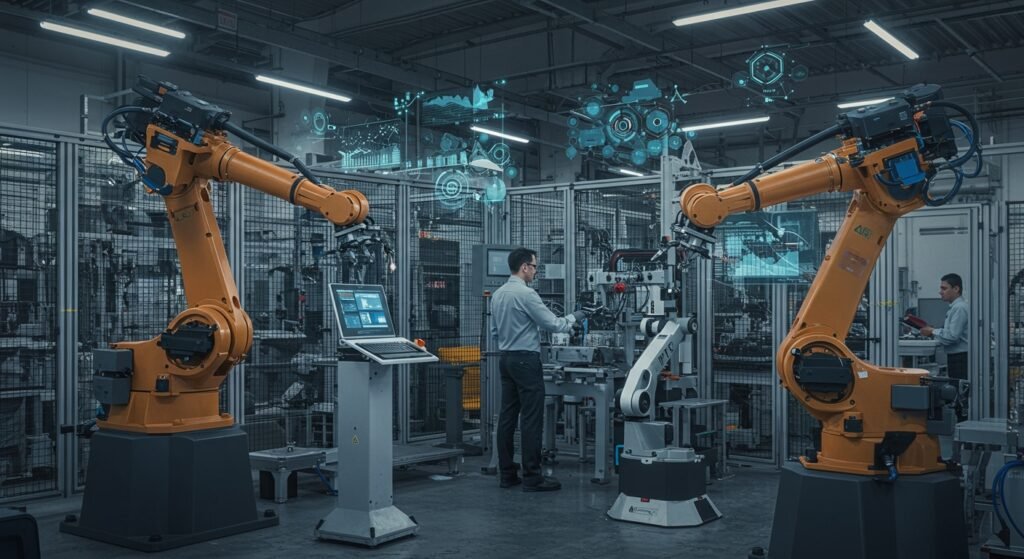

Traditional automation in industry involves the use of large, fixed-position industrial robots, automated guided vehicles (AGVs), and complex machinery designed for high-volume, repetitive tasks. These systems are typically found in automotive assembly lines, heavy manufacturing, and other sectors where precision, speed, and safety from human interaction are paramount. Such automation is characterized by its significant upfront investment, robust safety protocols often requiring protective caging, and a highly specialized programming environment. While incredibly efficient for specific, unchanging tasks, their rigidity can be a drawback in environments demanding flexibility.

Pros and Cons of Traditional Industrial Automation

Traditional industrial automation offers unparalleled speed and accuracy for repetitive processes, drastically reducing cycle times and minimizing human error. It excels in environments that are dangerous or require heavy lifting, ensuring worker safety and consistency. However, these systems are often costly to implement and require extensive engineering for setup and reprogramming. Their lack of flexibility makes them less suitable for low-volume, high-mix production lines, and they typically operate in isolation from human workers, necessitating safety barriers.

The Rise of Cobots: Collaboration Redefined

Collaborative robots, or cobots, represent a newer paradigm in industrial automation. Designed to work safely alongside humans without the need for extensive caging, cobots are smaller, lighter, and more adaptable. They are often equipped with advanced sensors and safety features that allow them to detect and react to human presence. Their ease of programming, often through lead-through training or intuitive interfaces, makes them accessible to a wider range of businesses, including small and medium-sized enterprises (SMEs).

Advantages and Limitations of Collaborative Robots

Cobots shine in their ability to enhance human capabilities rather than replace them entirely. They can take over dull, dirty, or dangerous tasks, freeing human workers for more complex or creative roles. Their flexibility allows for rapid redeployment across different tasks and production lines, making them ideal for variable production environments. The initial investment for cobots is generally lower than for traditional industrial robots. However, cobots typically have lower payloads and speeds compared to their industrial counterparts, making them unsuitable for heavy-duty or extremely high-speed applications. Their collaborative nature also means they must operate at speeds safe for human interaction, potentially limiting peak output.

Automation in Industry vs. Cobots: A Comparative Analysis

When considering automation in industry, the choice between traditional robots and cobots often comes down to the specific application, desired scale, and required flexibility. While traditional automation delivers brute force, speed, and precision for mass production, cobots offer agility, affordability, and the unique advantage of human-robot collaboration. Many companies are finding that the most effective strategy involves a blend of both, leveraging traditional robots for core, high-volume tasks and deploying cobots to support flexible, human-centric operations. To illustrate the key differences, consider the following table:

| Feature | Traditional Industrial Automation | Collaborative Robots (Cobots) |

|---|---|---|

| Investment | High | Moderate |

| Speed & Payload | High (heavy duty) | Moderate (light to medium duty) |

| Flexibility | Low (fixed tasks) | High (redeployable) |

| Safety Requirements | Extensive Caging | Advanced Sensors, Human-Safe Design |

| Programming | Complex, Specialized | Intuitive, Lead-Through Training |

| Human Interaction | Minimal/None (isolated) | Direct Collaboration |

| Best Use Case | Mass Production, Dangerous Tasks | Batch Production, Assembly, Machine Tending, Quality Control |

Strategic Implementation for Maximum Productivity Gains

Achieving optimal productivity gains in 2025 requires a strategic approach to integrating automation. This isn’t a one-size-fits-all decision but a careful assessment of operational needs and long-term goals. For instance, a factory producing thousands of identical components might lean heavily on traditional automation in industry for its speed and consistency. Conversely, a custom fabrication shop might find cobots invaluable for their adaptability and ease of programming, allowing them to shift quickly between different product lines.

Identifying Your Needs

Before investing, evaluate your production volume, product variety, available floor space, and the nature of tasks that could be automated. Are tasks repetitive and high-volume? Traditional automation might be best. Are tasks varied, requiring human dexterity and decision-making, but also needing assistance with repetitive actions? Cobots are likely a better fit. Consider the long-term impact on your workforce and how new technologies can upskill your employees rather than simply replacing them. For more insights on optimizing factory layouts, you can read more about industrial efficiency strategies here.

Integrating Technologies

The future isn’t about choosing one over the other, but about creating synergistic systems. Imagine traditional robots handling heavy stamping, while cobots perform final assembly and quality checks alongside human technicians. This hybrid approach allows businesses to capitalize on the strengths of both, building resilient and highly efficient production ecosystems. The integration of advanced analytics and AI will further enhance these systems, enabling predictive maintenance and dynamic task allocation, pushing the boundaries of what is possible in automated manufacturing.

Future Outlook: Synergies and Evolution

Looking ahead to 2025 and beyond, the line between traditional industrial automation and collaborative robots will continue to blur. Advances in AI, machine learning, and sensor technology will make industrial robots more adaptable, while cobots will gain greater payload capacity and speed. The ultimate goal is a highly flexible, intelligent factory floor where humans and machines work seamlessly, each contributing their unique strengths. This evolution promises not just productivity gains but also a safer, more engaging work environment, fostering innovation and sustainable growth. For deeper technical specifications and industry trends, consider resources like The Association for Advancing Automation (A3).