5 Unbelievable Ways Digital Twins in Industrial Systems Boost Efficiency

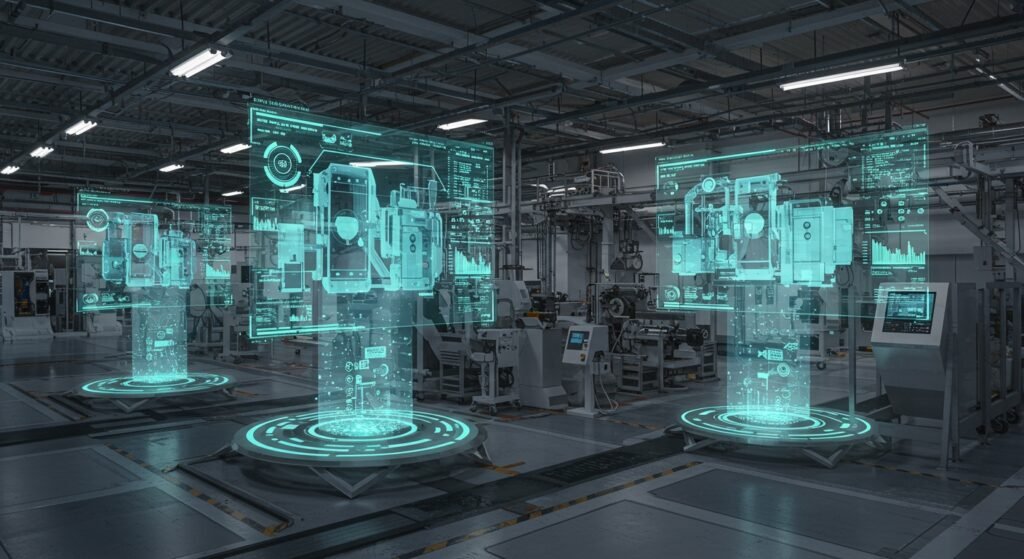

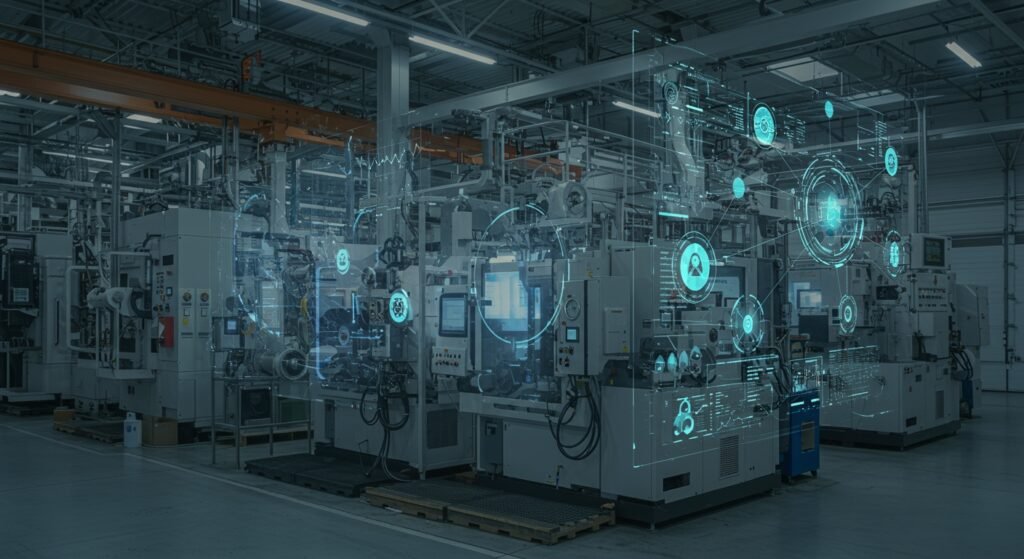

Digital Twins in Industrial Systems: Revolutionizing Operations The advent of Digital Twins in Industrial Systems marks a pivotal shift in how industries approach design, operations, and maintenance. By creating virtual replicas of physical assets, processes, or even entire facilities, digital twins offer unparalleled insights and control, paving the way for a new era of efficiency […]

5 Unbelievable Ways Digital Twins in Industrial Systems Boost Efficiency Read More »