Digital Twins in Smart Factories: A Guide for Industrial Engineers

The landscape of manufacturing is undergoing a profound transformation, largely driven by the advent of Industry 4.0. At the heart of this revolution lies digital twin technology, a sophisticated innovation that is reshaping how smart factories operate. For industrial engineers, understanding and leveraging digital twins is no longer optional; it’s a necessity for maintaining competitive advantage and driving efficiency in complex production environments.

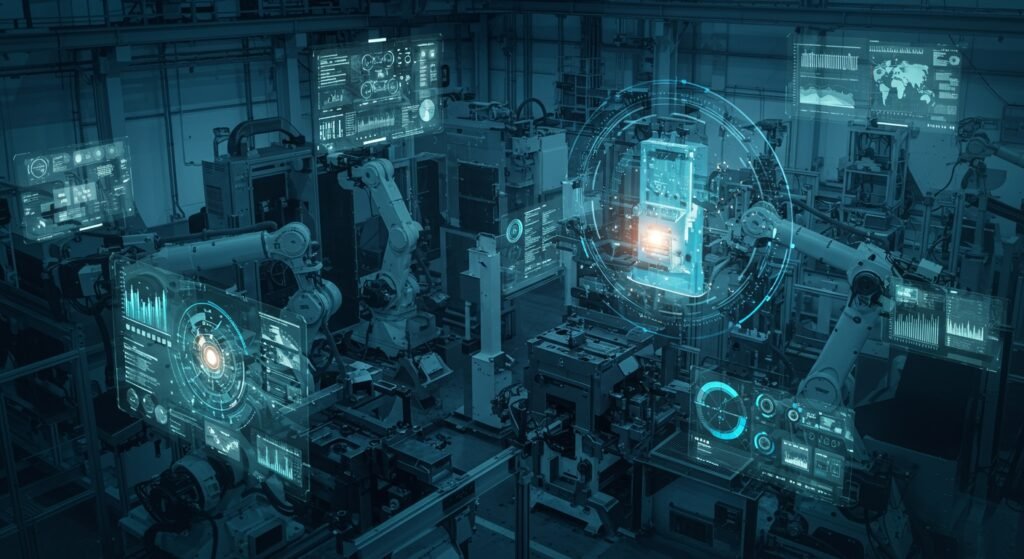

A digital twin is a virtual replica of a physical asset, process, or system. It acts as a bridge between the physical and digital worlds, collecting real-time data from sensors attached to its physical counterpart. This data is then used to simulate, monitor, and optimize the physical entity’s performance. In smart factories, this means creating virtual models of machines, production lines, and even entire facilities, allowing engineers to gain unprecedented insights and control.

Table of Contents

- What is Digital Twin Technology?

- Benefits of Digital Twins in Smart Factories

- Key Applications for Industrial Engineers

- Implementation: Challenges and Solutions

- Conclusion

What is Digital Twin Technology?

At its core, digital twin technology is a virtual model designed to accurately reflect a physical object. The digital twin receives continuous data from its physical counterpart through sensors, allowing it to reflect its real-time status, working condition, or position. This constant synchronization means that any change or action in the physical world is immediately mirrored in the digital realm, and vice-versa. This dynamic relationship enables a deeper level of analysis and predictive capability than ever before.

The Core Concept

The concept revolves around three main components: the physical product, the digital twin, and the connection between them. Sensors on the physical asset collect data on everything from temperature and pressure to operational efficiency and wear. This data is then fed into the digital model, which uses advanced analytics, machine learning, and artificial intelligence to process and interpret it. This allows industrial engineers to run simulations, predict potential failures, and experiment with changes without impacting the actual production line.

Benefits of Digital Twins in Smart Factories

The integration of digital twins offers a myriad of benefits for modern smart factories, leading to significant improvements across various operational facets.

Enhanced Process Optimization

One of the most compelling advantages is the ability to achieve unprecedented levels of process optimization. By simulating entire production lines or specific workstations, industrial engineers can identify bottlenecks, test new configurations, and refine workflows in a virtual environment. This reduces downtime, minimizes waste, and maximizes throughput before any physical changes are made, significantly boosting efficiency and profitability.

Predictive Maintenance

Digital twins enable a shift from reactive to proactive maintenance strategies. By continuously monitoring the health and performance of machinery, the digital twin can predict potential failures before they occur. This allows maintenance teams to schedule interventions precisely when needed, preventing costly breakdowns, extending asset lifespans, and ensuring continuous operation. For more on advanced maintenance strategies, see this insightful resource on Industry Week’s article on digital twins in predictive maintenance.

Improved Quality Control

Through real-time monitoring and data analysis, digital twins can detect anomalies in product quality or manufacturing processes. They can highlight deviations from expected standards, allowing for immediate corrective actions. This leads to higher product quality, fewer defects, and reduced recall risks, ultimately enhancing customer satisfaction and brand reputation.

Key Applications for Industrial Engineers

The practical applications of digital twin technology are vast and deeply impactful for industrial engineers.

Virtual Commissioning and Simulation

Industrial engineers can use digital twins for virtual commissioning, simulating the operation of new equipment or entire factory layouts before physical installation. This helps in identifying design flaws, optimizing control systems, and validating automation logic, thereby accelerating deployment and reducing costly rework. The power of virtual simulation is immense in mitigating risks associated with new deployments.

Real-time Monitoring of Production Systems

With digital twins, engineers gain a comprehensive, real-time view of all production systems. Dashboards powered by twin data can display key performance indicators (KPIs), operational status, and impending issues. This allows for immediate intervention, dynamic scheduling adjustments, and proactive problem-solving, ensuring smooth and efficient operations of the entire factory.

Supply Chain Optimization

Beyond the factory floor, digital twins can be extended to model and optimize supply chain processes. By simulating logistics, inventory management, and demand forecasting, engineers can identify inefficiencies, improve responsiveness, and enhance overall supply chain resilience. This holistic view provides critical insights for strategic decision-making.

Implementation: Challenges and Solutions

While the benefits are clear, implementing digital twin technology is not without its challenges. These often include data integration complexity, cybersecurity concerns, and the need for specialized skills. Organizations must invest in robust IoT infrastructure, secure data protocols, and continuous training for their workforce. Collaboration with technology partners and a phased implementation approach can help overcome these hurdles.

Comparing Traditional vs. Digital Twin Approaches

| Feature | Traditional Approach | Digital Twin Approach |

|---|---|---|

| Maintenance | Reactive (break-fix) | Predictive, Proactive |

| Process Optimization | Trial-and-error, Manual analysis | Virtual simulation, Data-driven insights |

| New Line Setup | Physical prototyping, Extensive testing | Virtual commissioning, Rapid validation |

| Data Insights | Limited, Historical | Real-time, Comprehensive, Predictive |

For further reading on the broader context of smart manufacturing, consider exploring our article on Understanding Industry 4.0 Basics.

Conclusion

Digital twin technology represents a monumental leap forward for smart factories and industrial engineering. By providing a dynamic, virtual replica of physical assets and processes, it empowers engineers to optimize operations, predict maintenance needs, enhance quality, and accelerate innovation. Embracing digital twins is not just about adopting a new tool; it’s about fundamentally rethinking how factories are designed, operated, and maintained, paving the way for a more efficient, resilient, and intelligent manufacturing future.