The Transformative Power of Digital Twins in Industrial Systems

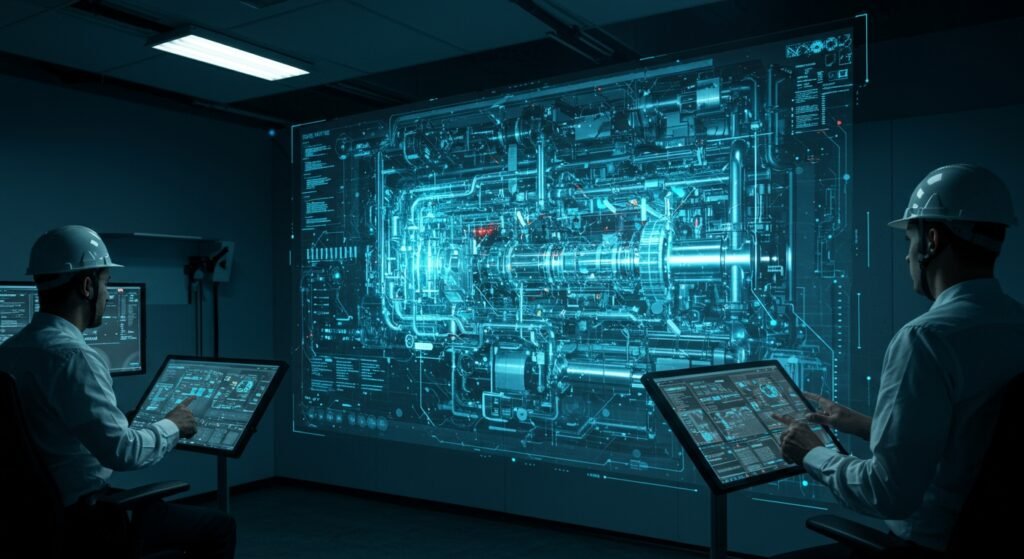

The industrial landscape is undergoing a profound transformation, driven by advancements in technology and the relentless pursuit of efficiency. At the forefront of this revolution are Digital Twins in Industrial Systems – virtual replicas of physical assets, processes, or systems that bridge the gap between the physical and digital worlds. These sophisticated models offer unprecedented insights, enabling companies to monitor, analyze, and optimize operations in real-time, predicting potential issues before they arise and fostering a new era of proactive management. This article delves into the critical role and immense potential of digital twin technology in modern industrial environments.

Table of Contents

- What Are Digital Twins?

- Key Benefits of Digital Twins in Industrial Systems

- Overcoming Implementation Challenges

- Real-World Impact: Digital Twin Case Studies

- The Future of Digital Twins in Industrial Systems

- Conclusion

What Are Digital Twins?

A digital twin is essentially a virtual model of a physical object or system. It’s not just a 3D model; it’s a dynamic, living replica that receives real-time data from its physical counterpart via sensors, IoT devices, and other data sources. This continuous data flow allows the digital twin to accurately reflect the physical asset’s current state, behavior, and performance. In an industrial context, this could be anything from a single pump or a complex manufacturing line to an entire factory or supply chain. The accuracy and real-time nature of these twins make them invaluable tools for decision-making and operational excellence.

Key Benefits of Digital Twins in Industrial Systems

The adoption of digital twins brings a multitude of advantages to industrial operations, fundamentally changing how businesses approach asset management, maintenance, and process optimization. Here are some of the most significant benefits:

Predictive Maintenance and Anomaly Detection

One of the most compelling benefits is the shift from reactive or preventive maintenance to predictive maintenance. By continuously monitoring the digital twin, engineers can identify anomalies and predict potential equipment failures long before they occur. This allows for scheduled maintenance, reducing downtime and extending the lifespan of critical assets. For more insights on this, you might explore external resources like IBM’s definition of Digital Twin.

Optimized Performance and Efficiency

Digital twins enable comprehensive simulation and analysis of various operational scenarios without disrupting the physical system. Companies can test changes, optimize parameters, and fine-tune processes in a virtual environment, ensuring maximum efficiency and output before deployment. This level of optimization leads to significant cost savings and improved productivity across the board.

Enhanced Design and Prototyping

Before physical production, digital twins can be used to design, test, and refine products or systems virtually. This accelerates the design cycle, reduces the need for expensive physical prototypes, and allows for early identification and correction of design flaws, leading to higher quality final products.

Remote Monitoring and Control

With digital twins, operators can monitor the status and performance of remote assets from anywhere in the world. This capability is crucial for geographically dispersed operations or hazardous environments, enabling quick responses to issues and reducing the need for on-site presence. For related internal content, see our article on Industrial IoT Implementation.

Overcoming Implementation Challenges

While the benefits are clear, implementing Digital Twins in Industrial Systems isn’t without its hurdles. Key challenges include the initial investment in IoT sensors and infrastructure, data integration from disparate systems, cybersecurity concerns, and the need for specialized skills to manage and interpret the vast amounts of data generated. However, with careful planning, phased implementation, and strategic partnerships, these challenges can be effectively addressed, paving the way for successful adoption.

Real-World Impact: Digital Twin Case Studies

Companies across various industrial sectors are already leveraging digital twin technology to achieve remarkable results. Here’s a brief look at how some industries are benefiting:

| Industry | Application | Benefit |

|---|---|---|

| Manufacturing | Optimizing production lines | Reduced downtime by 15%, increased throughput |

| Aerospace | Monitoring aircraft engines | Predictive maintenance, extended component lifespan |

| Energy | Managing wind turbines | Optimized energy generation, reduced operational costs |

| Healthcare | Hospital operational efficiency | Improved patient flow, resource allocation |

The Future of Digital Twins in Industrial Systems

The trajectory for digital twin technology points towards even deeper integration with artificial intelligence (AI), machine learning (ML), and virtual/augmented reality (VR/AR). As these technologies mature, digital twins will become even more intelligent, capable of autonomous decision-making and offering immersive experiences for interaction. The scope will expand beyond individual assets to entire ecosystems, enabling holistic optimization of supply chains, smart cities, and complex infrastructure projects. The relentless pursuit of industrial engineering excellence ensures that digital twins will remain a cornerstone of innovation.

Conclusion

Digital Twins in Industrial Systems represent a paradigm shift, offering unparalleled opportunities for efficiency, innovation, and strategic foresight. By creating dynamic, real-time virtual models of physical assets and processes, industries can unlock new levels of performance, reduce costs, and enhance decision-making. While implementation requires careful planning, the long-term benefits in terms of operational excellence and competitive advantage are undeniable. Embracing this technology is no longer an option but a necessity for any industrial entity striving to thrive in the era of Industry 4.0.