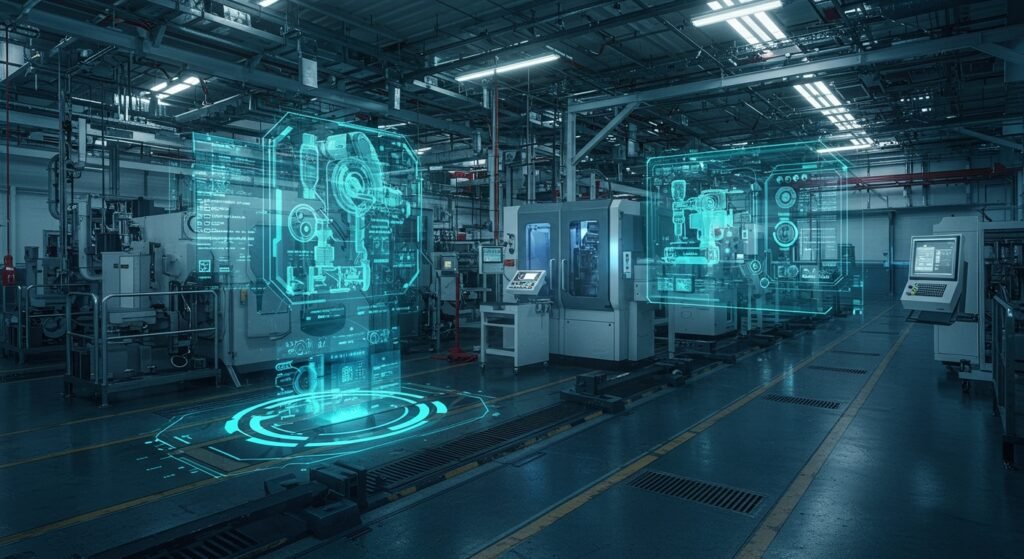

The industrial landscape is undergoing a profound transformation, driven by advancements in technology and a relentless pursuit of efficiency. At the heart of this revolution lies the concept of Digital Twins in Industrial Systems. These virtual replicas of physical assets, processes, and systems are not merely static models; they are dynamic, living entities that provide real-time insights, enabling organizations to optimize operations, predict failures, and innovate with unprecedented agility. Embracing digital twins is no longer a luxury but a strategic imperative for businesses aiming to thrive in the era of Industry 4.0.

Table of Contents

- What Are Digital Twins?

- Revolutionary Benefits of Digital Twins in Industrial Systems

- Applications Across Industries

- Challenges and Future Outlook

- Traditional vs. Digital Twin Systems: A Comparison

What Are Digital Twins?

A digital twin is a virtual representation that serves as the real-time digital counterpart of a physical object or process. It’s a bridge between the physical and digital worlds, allowing for real-time data exchange and analysis.

Defining the Concept

At its core, a digital twin is a dynamic software model of a physical thing or system. It continuously receives data from its physical counterpart through sensors, updating its virtual state. This constant synchronization means the digital twin accurately reflects the physical object’s performance, condition, and status at any given moment.

Key Components of a Digital Twin

For a digital twin to function effectively, several key components must be integrated:

- The Physical Product: The asset, process, or system being twinned, equipped with sensors.

- The Virtual Model: A detailed digital representation that mimics the physical product’s behavior and characteristics.

- Data Connection: A robust communication link that transmits real-time data from the physical asset to its digital twin.

- Data Processing & Analytics: Algorithms and AI capabilities that analyze the incoming data, providing insights and predicting future behavior.

- Human Interaction: Interfaces that allow operators and engineers to interact with the digital twin, receive insights, and send commands.

Revolutionary Benefits of Digital Twins in Industrial Systems

The adoption of Digital Twins in Industrial Systems brings a multitude of advantages that directly impact operational efficiency, cost reduction, and innovation.

Enhanced Operational Efficiency and Optimization

Digital twins provide a holistic, real-time view of operations, enabling companies to monitor performance, identify bottlenecks, and optimize processes. By simulating different scenarios, businesses can make data-driven decisions that lead to significant improvements in throughput, resource utilization, and overall productivity. This real-time insight allows for agile adjustments, ensuring peak performance around the clock.

Revolutionizing Predictive Maintenance

One of the most impactful applications of digital twins is in predictive maintenance. By continuously analyzing data from physical assets, digital twins can accurately predict when a component is likely to fail. This allows for proactive maintenance scheduling, minimizing costly downtime, extending asset lifespan, and reducing the need for emergency repairs. To learn more about how this technology is transforming asset management, you can learn more about predictive maintenance.

Accelerated Product Design and Development

Digital twins allow engineers to virtually test and validate new product designs or modifications without the need for physical prototypes. This significantly reduces development cycles, cuts costs, and enables rapid iteration based on simulated performance data. Issues can be identified and resolved in the digital realm before any physical production begins, ensuring higher quality and faster time-to-market.

Applications Across Industries

The versatility of digital twin technology means it is finding impactful applications across a diverse range of industrial sectors.

Manufacturing and Production

In manufacturing, digital twins optimize entire production lines, from raw material intake to final product delivery. They enable real-time tracking of work-in-progress, identify quality deviations, and allow for dynamic reallocation of resources, leading to smarter factories and more resilient supply chains.

Energy and Utilities

Digital twins are crucial for managing complex energy grids, optimizing renewable energy asset performance (like wind turbines or solar farms), and ensuring the efficient distribution of power. They help in predicting energy demand, identifying potential grid instabilities, and maximizing asset uptime for critical infrastructure.

Challenges and Future Outlook

While the benefits are clear, implementing digital twin technology comes with its own set of challenges, though the future promises even greater integration and sophistication.

Overcoming Implementation Hurdles

The primary challenges involve the complexity of data integration from disparate systems, ensuring robust cybersecurity for sensitive operational data, and the initial investment cost. Companies also need to cultivate new skill sets within their workforce to manage and leverage these advanced systems effectively.

The Road Ahead for Digital Twins

The future of digital twins is bright, with ongoing advancements in AI, machine learning, and edge computing set to enhance their capabilities further. As these technologies mature, digital twins will become even more autonomous, predictive, and interconnected, forming the backbone of truly smart industrial ecosystems. Expect to see deeper integration with related concepts like Industrial IoT trends, further blurring the lines between the physical and digital.

Traditional vs. Digital Twin Systems: A Comparison

| Feature | Traditional Industrial Systems | Digital Twin Systems |

|---|---|---|

| Monitoring | Manual, periodic, reactive | Real-time, continuous, proactive |

| Maintenance | Scheduled, breakdown-driven | Predictive, condition-based |

| Optimization | Trial-and-error, historical data | Simulation-driven, data-led |

| Fault Detection | Post-failure, diagnostic | Pre-failure, prognostic |

| Innovation Speed | Slow, physical prototyping | Fast, virtual simulation |

In conclusion, Digital Twins in Industrial Systems are fundamentally reshaping how industries operate, offering unparalleled opportunities for efficiency, innovation, and resilience. By bridging the gap between physical assets and their digital counterparts, businesses can unlock new levels of performance, making smarter decisions and forging a path toward a more optimized and sustainable future. The journey towards a fully ‘twinned’ industrial world is well underway, promising a transformative impact on global manufacturing and beyond.