Unlocking Efficiency: 7 Revolutionary Benefits of Digital Twins in Industrial Systems

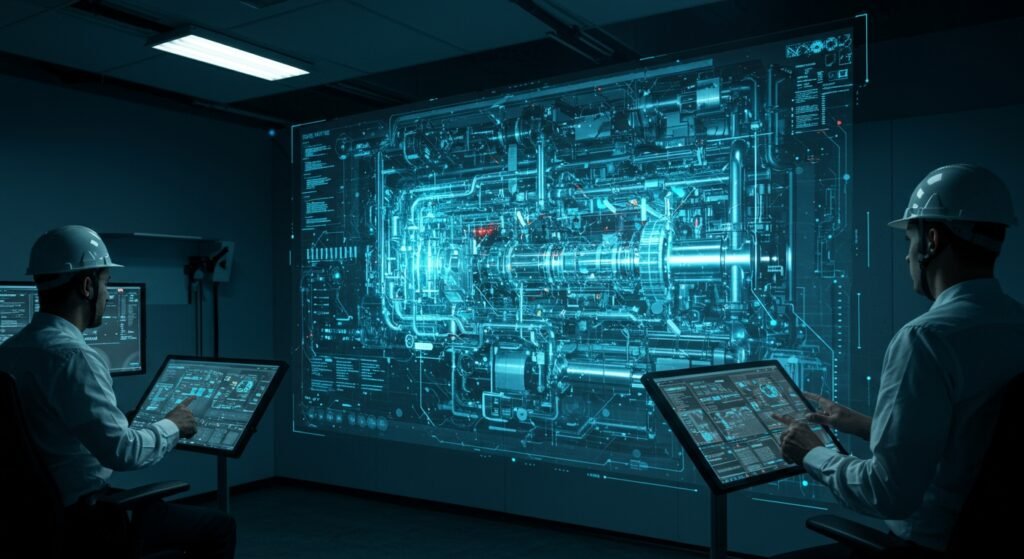

The advent of Industry 4.0 has ushered in a new era of technological innovation, with Digital Twins in Industrial Systems emerging as a cornerstone of modern operational efficiency. Far from being just a buzzword, digital twins represent a paradigm shift in how industries manage, optimize, and innovate their physical assets and processes. They are dynamic virtual models that mirror a physical object, system, or process, allowing for real-time monitoring, simulation, and analysis. This article explores the profound impact and transformative benefits of integrating digital twins into industrial environments.

Table of Contents

- What Are Digital Twins?

- How Digital Twins Work

- Key Benefits of Digital Twins in Industrial Systems

- Practical Use Cases Across Industries

- Challenges and The Future Outlook

- Conclusion

What Are Digital Twins?

A digital twin is a virtual replica of a physical entity, such as a machine, a production line, or even an entire factory. This replica is continuously updated with real-time data from sensors attached to its physical counterpart, allowing for an accurate and up-to-date representation of the physical asset’s state, performance, and behavior. The concept extends beyond mere simulation; it creates a living, breathing model that evolves with its physical twin.

The Evolution of Digital Twin Technology

While the idea of virtual models has been around for decades, modern digital twins are empowered by advancements in the Internet of Things (IoT), artificial intelligence (AI), machine learning (ML), and cloud computing. These technologies enable the collection, processing, and analysis of vast amounts of data, making the digital twin a powerful tool for informed decision-making.

How Digital Twins Work

At its core, a digital twin operates through a continuous feedback loop. Sensors on the physical asset collect data (e.g., temperature, pressure, vibration, operational status) and transmit it to the digital model. This data is then processed and analyzed by algorithms, often leveraging AI and ML, to provide insights into the asset’s current health, predict future performance, and simulate various scenarios. Operators can interact with the digital twin, run tests, and identify potential issues or optimizations without impacting the physical system.

Key Benefits of Digital Twins in Industrial Systems

The application of Digital Twins in Industrial Systems offers a multitude of advantages that revolutionize operational paradigms:

1. Enhanced Predictive Maintenance

One of the most significant benefits is the ability to predict equipment failures before they occur. By continuously monitoring asset health data, digital twins can identify anomalies and degradation patterns, enabling maintenance teams to schedule interventions precisely when needed. This approach significantly reduces unplanned downtime and extends asset lifespan, leading to substantial cost savings. Learn more about proactive strategies in our guide on predictive maintenance strategies.

2. Optimized Operational Efficiency

Digital twins provide a holistic view of operations, allowing companies to identify bottlenecks, optimize processes, and improve resource utilization. By simulating different operational parameters, engineers can discover the most efficient configurations, leading to increased throughput and reduced energy consumption.

3. Improved Product Design and Prototyping

Before physical prototyping, digital twins enable engineers to design, test, and refine products virtually. This accelerates the design cycle, reduces the number of costly physical prototypes needed, and allows for early identification and correction of design flaws, leading to higher quality products.

4. Remote Monitoring and Control

With digital twins, operators can monitor and, in some cases, even control physical assets from anywhere in the world. This capability is crucial for geographically dispersed operations or hazardous environments, enhancing safety and responsiveness.

5. Risk Mitigation and Safety

By simulating dangerous scenarios or operational stresses in a virtual environment, organizations can identify potential risks and develop robust mitigation strategies without endangering personnel or physical assets. This significantly improves workplace safety and reduces the likelihood of costly incidents.

6. Data-Driven Decision Making

Digital twins transform raw data into actionable insights. They provide a comprehensive, real-time understanding of industrial processes, empowering managers and engineers to make more informed decisions regarding asset management, resource allocation, and strategic planning.

7. Collaborative Innovation

The shared virtual model facilitates collaboration among different departments, stakeholders, and even external partners. Designers, engineers, maintenance crews, and management can all work with the same accurate representation of the asset, fostering cross-functional innovation and problem-solving.

| Feature | Traditional Operations | Digital Twin Enhanced Operations |

|---|---|---|

| Maintenance Strategy | Reactive/Time-based | Predictive/Prescriptive |

| Downtime | High (unplanned) | Low (planned) |

| Decision Making | Experience/Historical data | Real-time data/Simulation |

| Optimization Scope | Limited to physical constraints | Extensive (virtual testing) |

| Cost Efficiency | Higher operational costs | Reduced operational costs |

Practical Use Cases Across Industries

Digital twins are being adopted across a diverse range of industrial sectors:

- Manufacturing: Optimizing production lines, monitoring machinery health, and simulating new product introductions.

- Energy and Utilities: Managing smart grids, optimizing power generation assets, and predicting infrastructure failures for greater reliability.

- Aerospace: Monitoring aircraft engine performance, predicting maintenance needs, and simulating flight conditions for design improvements.

- Healthcare: Creating ‘hospital digital twins’ to optimize patient flow, resource allocation, and even simulating complex surgeries.

- Construction: Planning building lifecycles, monitoring structural integrity, and optimizing facility management.

Challenges and The Future Outlook

While the benefits are clear, implementing digital twins comes with challenges, including significant initial investment, data security concerns, and the need for specialized skills. Organizations must ensure robust data governance and cybersecurity measures are in place. As discussed by experts at the Industrial Internet Consortium, standardization and interoperability are also key for broader adoption.

The future of digital twins is bright, with continued advancements in AI, machine learning, and augmented reality (AR) poised to make these virtual models even more intelligent and immersive. We can expect more comprehensive ‘system of systems’ digital twins, where multiple individual twins interact to form a broader, integrated model of an entire enterprise or city. This will further blur the lines between the physical and digital worlds, driving unprecedented levels of efficiency and innovation across all industries.

Conclusion

Digital Twins in Industrial Systems are not just a technological advancement; they are a strategic imperative for businesses aiming to thrive in the era of Industry 4.0. By providing real-time insights, enabling predictive capabilities, and fostering innovation, digital twins empower organizations to unlock new levels of efficiency, reduce costs, enhance safety, and accelerate their journey towards a truly smart and sustainable future. Embracing this transformative technology is key to maintaining a competitive edge in the rapidly evolving industrial landscape.