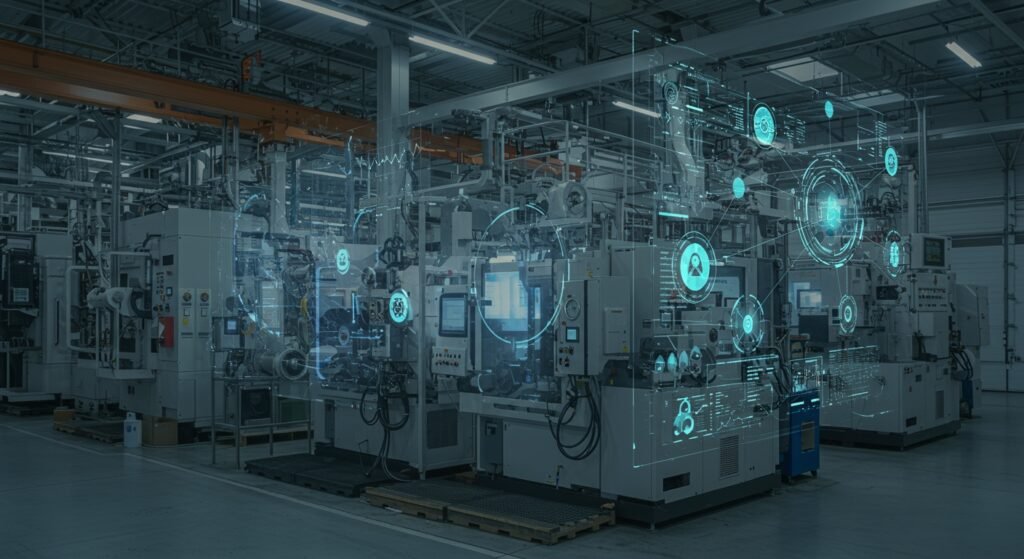

In the rapidly evolving landscape of Industry 4.0, the concept of Digital Twins in Industrial Systems has emerged as a transformative technology. Far more than just a 3D model, a digital twin is a virtual replica of a physical asset, process, or system that serves as an indispensable tool for real-time monitoring, simulation, and analysis. This innovative approach promises to redefine how industries operate, offering unprecedented insights into performance, potential issues, and optimization opportunities.

Table of Contents

- What Are Digital Twins?

- The Core Benefits of Digital Twins in Industrial Systems

- Key Applications Across Industries

- Implementing Digital Twins: Challenges and Considerations

- The Future Landscape of Digital Twins

What Are Digital Twins?

A digital twin is a dynamic virtual model that acts as a real-time digital counterpart of a physical object or system. It continuously receives data from its physical twin via sensors and other data sources, allowing for comprehensive monitoring, analysis, and simulation. This constant data exchange ensures the virtual model remains an accurate, up-to-date reflection of its physical counterpart, enabling predictive capabilities and proactive decision-making. Imagine a complex turbine or an entire manufacturing line having a living, breathing digital double that provides immediate feedback on its health and performance.

The Core Benefits of Digital Twins in Industrial Systems

The adoption of Digital Twins in Industrial Systems offers a multitude of advantages, significantly impacting efficiency, cost, and safety across various sectors. These benefits stem from the ability to analyze and predict the behavior of physical assets in a virtual environment.

Enhanced Predictive Maintenance

One of the most compelling benefits is the shift from reactive to predictive maintenance. Digital twins can simulate potential failures based on real-time data and historical performance, allowing companies to identify and address issues before they lead to costly downtime. This proactive approach minimizes disruptions and extends the lifespan of industrial machinery.

Optimized Operations and Efficiency

By providing a holistic view of operations, digital twins enable organizations to identify bottlenecks, optimize processes, and improve overall operational efficiency. Simulations can test different scenarios, such as production line adjustments or resource allocation, to find the most efficient setup without disrupting actual operations.

Improved Product Design and Prototyping

For product development, digital twins offer an invaluable sandbox. Engineers can create virtual prototypes, test designs, and iterate rapidly, significantly reducing the time and cost associated with physical prototyping. This leads to faster time-to-market and more robust product designs.

Risk Mitigation and Safety

Simulating hazardous scenarios in a safe, virtual environment allows industries to train personnel, test safety protocols, and understand the potential impact of equipment failures without putting lives at risk. This capability is crucial in high-risk environments like energy generation or chemical processing.

Key Applications Across Industries

The versatility of digital twin technology means its applications span across a wide array of industrial sectors, each benefiting from its unique capabilities.

Manufacturing

In manufacturing, digital twins are used for optimizing production lines, monitoring machine health, and managing supply chains. They allow for real-time tracking of products, predicting equipment failures, and even simulating the impact of design changes on the manufacturing process.

Energy and Utilities

For power plants, grid management, and renewable energy installations, digital twins provide critical insights into asset performance and potential vulnerabilities. They can help optimize energy distribution, predict equipment wear in wind turbines or solar farms, and ensure the stability of the entire energy infrastructure. For more on how digital models are transforming sectors, you might consult GE Digital’s insights on digital twins.

Healthcare

While often associated with heavy industry, digital twins are also making inroads into healthcare, from optimizing hospital operations and equipment maintenance to creating personalized patient models for treatment planning and drug development.

Implementing Digital Twins: Challenges and Considerations

Despite their immense potential, the successful implementation of digital twin technology comes with its own set of challenges. These include the significant investment in sensor technology and data infrastructure, the complexity of integrating diverse data sources, and the need for specialized skills in data analytics and modeling. Organizations must also address data security and privacy concerns, as digital twins often handle sensitive operational data. A phased approach, starting with smaller, manageable projects, can help mitigate these challenges.

The Future Landscape of Digital Twins

The future of digital twins is inextricably linked with advancements in AI, machine learning, and the Industrial Internet of Things (IIoT). As these technologies mature, digital twins will become even more sophisticated, offering enhanced predictive capabilities, autonomous decision-making, and seamless integration across entire enterprise ecosystems. They are poised to become a foundational element of smart factories and smart cities, driving an era of unprecedented operational intelligence and efficiency. The continuous evolution of these technologies will further solidify the role of digital twins as indispensable tools for industrial innovation.

| Feature | Traditional System Management | Digital Twin Approach |

|---|---|---|

| Maintenance | Reactive/Scheduled | Predictive/Proactive |

| Troubleshooting | Physical inspection, trial & error | Virtual simulation, root cause analysis |

| Optimization | Based on historical data/manual adjustments | Real-time data-driven, continuous simulation |

| Risk Assessment | Limited by physical testing | Extensive virtual scenario testing |

In conclusion, the transformative power of Digital Twins in Industrial Systems is undeniable. By bridging the gap between the physical and digital worlds, they empower industries with the insights needed to optimize operations, enhance safety, and drive innovation, ensuring a resilient and efficient future.