The Role of Edge Computing in Industrial Predictive Maintenance

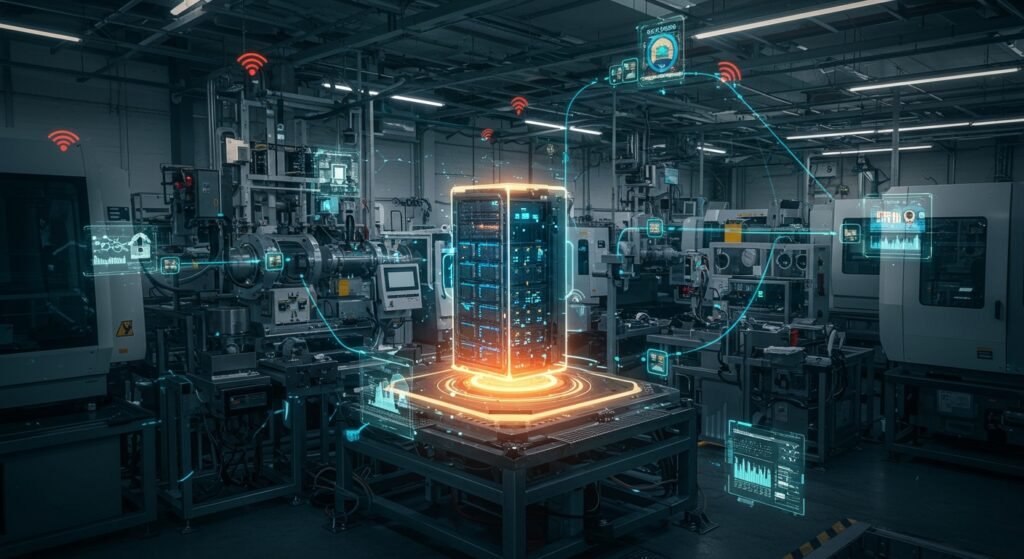

The industrial landscape is undergoing a profound transformation, driven by advancements in technology. At the forefront of this evolution is edge computing, a distributed computing paradigm that brings computation and data storage closer to the sources of data. This approach is particularly transformative for industrial predictive maintenance, where real-time insights can prevent costly downtimes and optimize operational efficiency. Traditional cloud-based systems, while powerful, often introduce latency that can be critical in time-sensitive industrial applications. Edge computing mitigates this by processing data locally, enabling immediate decision-making and rapid responses to potential equipment failures.

Table of Contents

- 1. Introduction to Edge Computing and Predictive Maintenance

- 2. Why Edge Computing Matters for Industrial Applications

- 3. Key Benefits of Edge Computing in Predictive Maintenance

- 4. How Edge Computing Works in Predictive Maintenance

- 5. Implementing Edge Computing for Industrial Assets

- 6. Challenges and Future Outlook

- 7. Conclusion

1. Introduction to Edge Computing and Predictive Maintenance

The convergence of the Industrial Internet of Things (IIoT) and advanced analytics has paved the way for predictive maintenance strategies. Instead of reactive or scheduled maintenance, predictive maintenance leverages data from sensors to anticipate equipment failures before they occur. This proactive approach significantly reduces unexpected downtime, extends asset lifespan, and optimizes maintenance schedules. However, the sheer volume and velocity of data generated by industrial machinery pose a challenge for traditional centralized cloud architectures. This is where edge computing steps in, offering a decentralized solution for processing data closer to its source.

2. Why Edge Computing Matters for Industrial Applications

Industrial environments demand high reliability and immediate action. Sending all sensor data to a remote cloud for processing can be inefficient and risky. Latency can mean the difference between preventing a catastrophic failure and facing costly production halts. Edge devices, embedded directly within or near industrial equipment, can perform initial data filtering, aggregation, and analysis. This not only speeds up decision-making but also reduces the amount of data that needs to be transmitted to the cloud, saving bandwidth and associated costs. For more information on IIoT, you can visit a reliable source like I-SCOOP on IIoT.

3. Key Benefits of Edge Computing in Predictive Maintenance

The adoption of edge computing brings a multitude of advantages to industrial predictive maintenance.

3.1. Real-time Data Processing and Analysis

Perhaps the most significant benefit is the ability to process data in real-time. Sensors on industrial machines generate continuous streams of data about vibration, temperature, pressure, and more. Edge devices can analyze this data instantaneously, identifying anomalies or patterns indicative of impending failure without delay. This capability allows for immediate alerts and autonomous adjustments, preventing minor issues from escalating.

3.2. Reduced Latency and Faster Response

By performing computations at the “edge,” the time taken for data to travel to a central server and back (latency) is drastically cut. In critical industrial processes, milliseconds matter. Faster response times enable systems to react to changes, issue warnings, or even trigger automatic shutdowns to prevent damage, ensuring operational continuity and safety.

3.3. Enhanced Data Security and Privacy

Processing sensitive operational data locally at the edge reduces its exposure to external threats. Less data needs to be transmitted over public networks, minimizing potential attack vectors. Furthermore, organizations can maintain greater control over their proprietary information, adhering to strict industry regulations and compliance standards.

3.4. Cost Efficiency and Bandwidth Optimization

Transmitting vast quantities of raw sensor data to the cloud can incur significant bandwidth and storage costs. Edge computing allows for data pre-processing, filtering out irrelevant noise, and sending only critical or aggregated insights to the cloud. This optimizes network usage and reduces cloud infrastructure expenses, leading to substantial cost savings.

4. How Edge Computing Works in Predictive Maintenance

In a typical edge-enabled predictive maintenance setup, sensors collect data from various assets like motors, pumps, and conveyor belts. This raw data is then fed into edge devices (which could be industrial PCs, gateways, or even smart sensors) located on the factory floor. These devices run specialized analytics algorithms, often incorporating machine learning models, to identify deviations from normal operating parameters. For example, a sudden spike in vibration frequency could indicate a bearing failure.

If an anomaly is detected, the edge device can immediately trigger an alert for maintenance personnel, schedule a work order, or even make autonomous adjustments to machine parameters. Only relevant summary data or critical alarms are then sent to a central cloud platform for long-term storage, broader trend analysis, and strategic decision-making. This tiered architecture ensures that time-sensitive tasks are handled locally, while less urgent, aggregate data benefits from the scalability of the cloud.

5. Implementing Edge Computing for Industrial Assets

Successful implementation of edge computing for predictive maintenance requires careful planning and execution. Here’s a brief overview of key considerations:

| Aspect | Description | Key Challenge |

|---|---|---|

| Hardware Selection | Choosing robust edge devices capable of operating in harsh industrial environments. | Environmental durability and processing power. |

| Software & Analytics | Deploying appropriate AI/ML models for real-time data analysis. | Model accuracy and continuous learning. |

| Network Infrastructure | Ensuring reliable local network connectivity (e.g., Wi-Fi, Ethernet, 5G). | Bandwidth management and network security. |

| Data Integration | Seamlessly integrating data from various sensors and existing OT systems. | Interoperability across diverse protocols. |

Organizations must also consider the skills gap within their workforce, investing in training for personnel who will manage and maintain edge infrastructure. Moreover, cybersecurity becomes paramount, as edge devices represent new potential entry points into the operational technology (OT) network. An internal article on optimizing IIoT deployments provides further insights into integrating such technologies effectively.

6. Challenges and Future Outlook

While the benefits are clear, implementing edge computing is not without its challenges. These include the complexity of managing a distributed infrastructure, ensuring robust cybersecurity at the edge, and developing sophisticated AI/ML models that can run efficiently on resource-constrained edge devices. Interoperability between different vendors’ hardware and software also remains a hurdle.

However, the future for edge computing in industrial predictive maintenance looks bright. As 5G networks become more prevalent, providing ultra-low latency and high bandwidth, the capabilities of edge devices will expand even further. We can expect more sophisticated AI models deployed at the edge, leading to truly autonomous and self-optimizing industrial systems. The integration of augmented reality (AR) for maintenance technicians, leveraging real-time data from edge devices, also holds immense potential.

7. Conclusion

Edge computing is fundamentally reshaping industrial predictive maintenance, moving from a reactive to a highly proactive and efficient paradigm. By bringing computation closer to the source of data, it enables real-time insights, reduces latency, enhances security, and optimizes costs. As industries continue to embrace digital transformation, edge computing will undoubtedly play a critical role in ensuring the reliability, safety, and efficiency of their operations, unlocking unprecedented levels of productivity and extending the lifespan of valuable assets.