Future Trends in Industrial Engineering: Navigating the Next Era of Innovation

Industrial engineering, a field dedicated to optimizing complex processes, systems, and organizations, is on the cusp of a revolutionary transformation. As global challenges evolve and technology accelerates, the demand for more efficient, sustainable, and resilient industrial systems has never been higher. This article delves into the exciting Future trends that are not just reshaping the discipline but also dictating the trajectory of industries worldwide. From artificial intelligence to circular economy principles, industrial engineers are poised to lead the charge in creating smarter, more productive, and environmentally conscious operations.

Table of Contents

- The Rise of Artificial Intelligence and Machine Learning

- Automation and Robotics: The Next Frontier

- Sustainable and Green Industrial Practices

- Digital Twins and Simulation for Optimized Operations

- Reshaping Supply Chains with Advanced Analytics

- Challenges and Opportunities Ahead

- Conclusion

The Rise of Artificial Intelligence and Machine Learning

Artificial Intelligence (AI) and Machine Learning (ML) are no longer futuristic concepts; they are integral to modern industrial engineering. These technologies empower engineers to analyze vast datasets, predict outcomes with unprecedented accuracy, and optimize processes in real-time. Applications range from predictive maintenance, where AI algorithms anticipate equipment failures before they occur, to demand forecasting, which refines production schedules and inventory management. The ability of AI to learn from patterns and adapt to changing conditions makes it an indispensable tool for enhancing efficiency and reducing operational costs.

Predictive Analytics for Enhanced Efficiency

Predictive analytics, powered by machine learning, is transforming maintenance strategies. Instead of scheduled maintenance or reactive repairs, systems can now predict the optimal time for servicing, minimizing downtime and extending asset lifecycles. This data-driven approach not only saves significant resources but also ensures a more stable and continuous production flow, a critical advantage in today’s competitive landscape.

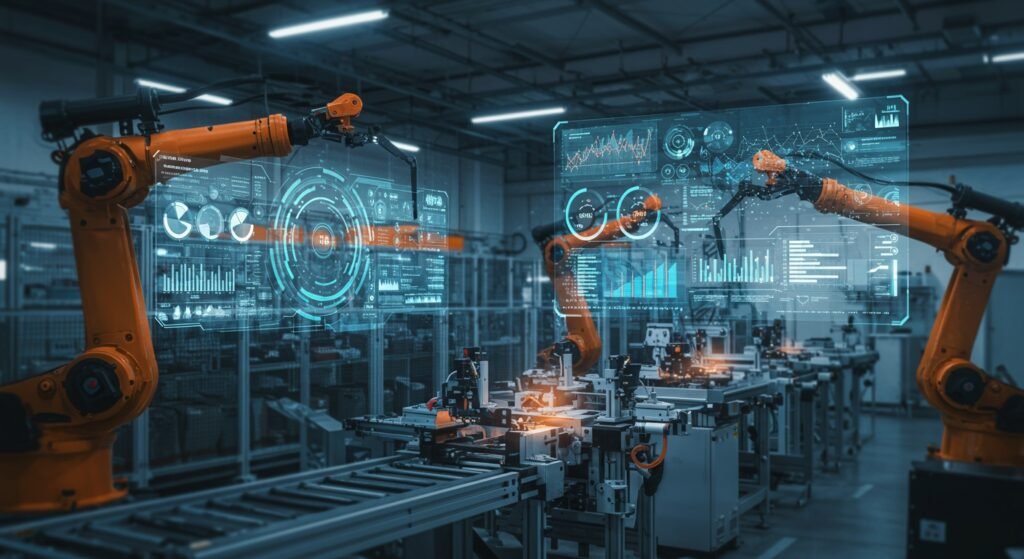

Automation and Robotics: The Next Frontier

Automation and robotics are evolving beyond simple repetitive tasks. The Future of industrial engineering involves sophisticated collaborative robots (cobots) that work alongside human operators, enhancing safety and precision. Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) are streamlining logistics within factories and warehouses, improving material handling efficiency. This integration of advanced robotics is leading to the development of ‘smart factories’ where machinery, sensors, and software are interconnected, allowing for self-optimizing production lines.

Collaborative Robotics and Human-Machine Interaction

Cobots are designed to share workspaces with humans, offering flexibility and adaptability that traditional industrial robots lack. They can assist with complex assembly tasks, quality control, and even dangerous operations, reducing human exposure to risk. This shift emphasizes a human-in-the-loop approach, where technology augments human capabilities rather than replacing them entirely, fostering a more productive and ergonomic work environment.

Sustainable and Green Industrial Practices

Sustainability is no longer an optional add-on but a core principle of industrial design and operation. Industrial engineers are at the forefront of developing processes that minimize environmental impact while maximizing resource efficiency. This includes implementing circular economy models, where waste is minimized, and resources are kept in use for as long as possible. Efforts are focused on reducing energy consumption, optimizing waste streams, and designing products for longevity, recyclability, and ease of disassembly.

Table: Traditional vs. Future Industrial Engineering Approaches

| Aspect | Traditional Approach | Future-Oriented Approach |

|---|---|---|

| Focus | Cost Reduction, Efficiency | Sustainability, Resilience, Ethics |

| Data Use | Retrospective, Manual | Real-time, Predictive, AI-driven |

| Workforce | Specialized, Repetitive | Collaborative, Augmented, Upskilled |

| Energy | Consumption, Cost | Efficiency, Renewable Sources |

| Waste | Disposal, Minimization | Circular Economy, Resource Recovery |

Digital Twins and Simulation for Optimized Operations

Digital twins—virtual replicas of physical assets, processes, or systems—are revolutionizing how industrial engineers design, operate, and maintain complex environments. By creating a digital counterpart, engineers can simulate various scenarios, test changes, and predict performance without disrupting physical operations. This capability is invaluable for optimizing factory layouts, testing new production lines, or troubleshooting issues in a controlled virtual environment, leading to faster innovation and reduced risks.

Reshaping Supply Chains with Advanced Analytics

The resilience and efficiency of global supply chains have been critically tested in recent years. Industrial engineers are leveraging advanced analytics, IoT (Internet of Things) sensors, and blockchain technology to create more transparent, robust, and responsive supply chains. Real-time data visibility allows for quicker adaptation to disruptions, while predictive analytics helps anticipate potential bottlenecks. Blockchain offers secure and immutable transaction records, enhancing traceability and trust across the entire supply network.

Challenges and Opportunities Ahead

Embracing these transformative trends comes with its own set of challenges. The need for a skilled workforce capable of operating and maintaining advanced systems is paramount. Upskilling existing employees and integrating new talent with expertise in AI, data science, and robotics will be crucial. Ethical considerations regarding AI deployment and data privacy also require careful navigation. However, the opportunities are immense: increased productivity, enhanced sustainability, greater resilience, and the potential to solve some of humanity’s most pressing problems through engineering innovation. For deeper insights into industry shifts, you might find valuable information on IndustryWeek.com. To understand how to prepare your team, consider reading our article on Upskilling for Industry 4.0.

Conclusion

The Future of industrial engineering is vibrant and full of potential. The integration of AI, robotics, sustainable practices, digital twins, and advanced analytics is not merely incremental change but a paradigm shift. Industrial engineers, equipped with these powerful tools and methodologies, are poised to design and implement systems that are not only efficient and profitable but also environmentally responsible and socially beneficial. The journey ahead demands continuous learning, adaptability, and a commitment to innovation, ensuring that industrial engineering remains a cornerstone of progress in the 21st century.