How Digital Twins Enable Real-Time Process Optimization

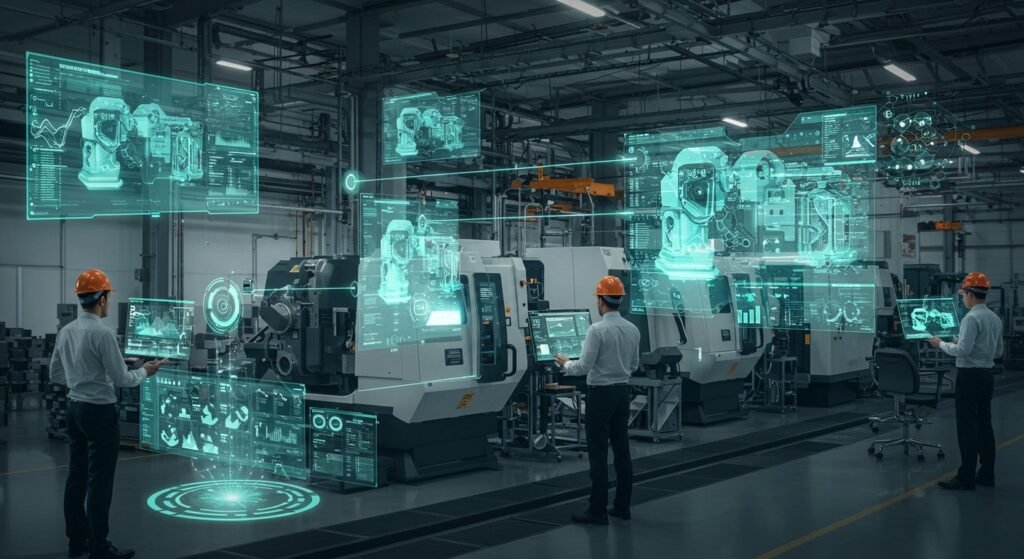

In the rapidly evolving landscape of Industry 4.0, businesses are constantly seeking innovative solutions to enhance efficiency, reduce costs, and accelerate decision-making. Among the most transformative technologies emerging is the concept of digital twins. A digital twin is a virtual replica of a physical asset, process, or system, continuously updated with real-time data from its real-world counterpart. This powerful connection allows for unprecedented insights and, critically, enables real-time process optimization, providing a significant competitive edge.

Table of Contents

- What Are Digital Twins?

- The Mechanism of Real-Time Optimization with Digital Twins

- Key Benefits of Implementing Digital Twins

- Digital Twins in Action: Industry Examples

- Challenges and Future Outlook

- Conclusion

What Are Digital Twins?

At its core, a digital twin is a dynamic, virtual model of a physical object or system. It’s not just a 3D model; it’s a sophisticated virtual construct that mirrors the behavior, properties, and state of its physical twin. Sensors on the physical object collect data—temperature, pressure, speed, performance metrics—and transmit it to the digital twin in real-time. This continuous data flow ensures that the virtual model remains a precise, up-to-the-minute representation of reality.

This technology leverages various advanced capabilities, including IoT (Internet of Things) for data collection, AI and machine learning for analysis and prediction, and sophisticated simulation software for scenario testing. The result is a living model that can be used for monitoring, analysis, diagnostics, and, most importantly, optimization.

The Mechanism of Real-Time Optimization with Digital Twins

The ability of digital twins to facilitate real-time process optimization stems from several interconnected mechanisms:

Data Integration and Synchronization

The foundation of any effective digital twin system is robust data integration. Data from sensors, PLCs, enterprise resource planning (ERP) systems, and manufacturing execution systems (MES) are continuously fed into the digital twin. This aggregated data provides a holistic view of the operational environment, reflecting the current state, performance, and environmental factors affecting the physical process.

Simulation and Predictive Analytics

Once synchronized, the digital twin becomes a powerful simulation platform. Engineers and operators can run ‘what-if’ scenarios, testing different operational parameters, maintenance schedules, or design changes in the virtual environment without impacting the physical system. Predictive analytics, powered by machine learning algorithms, can forecast potential failures, identify bottlenecks, and predict future performance based on current and historical data. This foresight is critical for proactive optimization.

Feedback Loops and Continuous Improvement

The true power of digital twins in real-time optimization lies in their closed-loop feedback mechanism. Insights gained from the digital twin—such as optimal settings for a machine, an ideal production flow, or an early warning of an impending issue—can be fed back to the physical system. This might involve automated adjustments to control systems or recommendations for human operators, leading to continuous improvement cycles. This iterative process ensures that the physical operation is always running at or near its peak efficiency.

Key Benefits of Implementing Digital Twins

Adopting digital twin technology offers a multitude of advantages for businesses striving for operational excellence:

Enhanced Efficiency and Productivity

By identifying inefficiencies, optimizing resource allocation, and streamlining workflows, digital twins significantly boost operational efficiency. Real-time insights allow for immediate adjustments, minimizing downtime and maximizing throughput.

Cost Reduction and Waste Minimization

Predictive maintenance capabilities help avoid costly breakdowns and extend the lifespan of assets. Optimized processes lead to reduced energy consumption, less material waste, and lower operational expenses. For a deeper dive into overall industrial efficiency, see our article on Understanding Industry 4.0.

Improved Decision-Making

With comprehensive, real-time data and simulation capabilities, decision-makers can make informed choices based on empirical evidence rather than guesswork. This leads to better strategic planning and tactical execution.

Risk Mitigation and Predictive Maintenance

Digital twins can simulate extreme conditions or potential failure modes safely in a virtual environment. This helps in identifying vulnerabilities and developing robust mitigation strategies. Predictive maintenance schedules, based on actual asset condition rather than arbitrary time intervals, significantly reduce unexpected failures and associated risks.

Digital Twins in Action: Industry Examples

The application of digital twins spans various industries, revolutionizing how companies manage their assets and processes.

| Aspect | Traditional Approach | Digital Twin Approach |

|---|---|---|

| Maintenance | Scheduled or Reactive | Predictive (condition-based) |

| Process Optimization | Manual adjustments, trial & error | Simulation-driven, real-time feedback |

| Problem Solving | Post-event analysis | Proactive detection, ‘what-if’ scenarios |

| Asset Lifecycle | Separate design, operation, end-of-life | Integrated, continuous monitoring & improvement |

In manufacturing, digital twins optimize production lines, predict equipment failures, and enable agile reconfigurations. In healthcare, they can model patient organs for personalized treatment plans or simulate hospital operations for better resource management. Smart cities use them to manage traffic flow, energy consumption, and infrastructure maintenance. The aerospace industry employs them for monitoring aircraft health and performance. Learn more about their impact on various sectors from Gartner’s insights on digital twin technology.

Challenges and Future Outlook

While the benefits are clear, implementing digital twins comes with challenges. These include the significant initial investment in sensors and integration platforms, the complexity of data management, and cybersecurity concerns. However, as technology advances and costs decrease, these hurdles are becoming more manageable.

The future of digital twins is exceptionally bright. We can expect to see increased adoption across all sectors, greater interoperability between different twin systems, and the development of ‘meta-twins’ that model entire ecosystems. This will further blur the lines between the physical and digital worlds, leading to even more sophisticated and autonomous optimization capabilities.

Conclusion

Digital twins are more than just a technological trend; they are a fundamental shift in how industries operate. By providing a real-time, dynamic bridge between physical assets and their virtual counterparts, they unlock unprecedented opportunities for process optimization. From enhancing efficiency and reducing costs to empowering informed decision-making and mitigating risks, digital twin technology is paving the way for a more intelligent, responsive, and productive future. Embracing this innovation is no longer an option but a strategic imperative for businesses aiming to thrive in the digital age.