Introduction to Industrial Engineering and Sustainability

Industrial engineering is a multifaceted discipline that focuses on optimizing complex systems, processes, and organizations. It combines principles from engineering, mathematics, and business to enhance efficiency, productivity, and quality in manufacturing environments. As industrial engineers strive to streamline operations and reduce waste, they play a pivotal role in promoting sustainability within the manufacturing sector. Sustainability, in this context, refers to the ability to meet current production demands without compromising the ability of future generations to meet their own needs. This dual focus on efficiency and environmental stewardship positions industrial engineering as a critical player in advancing sustainability initiatives.

In the manufacturing landscape, the push towards sustainable practices has become increasingly significant. Factors such as resource depletion, climate change, and regulatory pressures have motivated industries to adopt greener approaches. Industrial engineers are utilizing tools such as systems engineering, lean manufacturing, and life cycle analysis to implement sustainable practices effectively. By analyzing manufacturing processes and identifying areas where resources can be conserved, waste can be minimized, and energy consumption can be reduced, industrial engineers are not only benefiting manufacturers economically but also contributing to environmental protection.

The integration of industrial engineering principles with sustainability goals leads to innovative solutions that enhance both operational performance and ecological responsibility. Methods such as value stream mapping and process re-engineering are leveraged to develop sustainable workflows, thereby turning manufacturing plants into eco-efficient operations. As the demand for sustainable practices grows, industrial engineering is becoming increasingly essential in driving change throughout the industrial landscape.

Through strategic planning and application of engineering methodologies, industrial engineers are setting a precedent for innovation that aligns with sustainability objectives, thereby ensuring the resilience and competitiveness of the manufacturing sector in an environmentally-conscious future.

The Role of Industrial Engineers in Manufacturing

Industrial engineers play a critical role in the manufacturing sector by focusing on the optimization of complex processes and systems. Their primary responsibility lies in enhancing productivity while minimizing waste and resource consumption. This drive for efficiency is essential in today’s landscape, where sustainability has taken center stage. By applying various engineering principles, industrial engineers design workflows that streamline production processes, thereby reducing operational costs and increasing profitability for manufacturers.

One key function of industrial engineers is to analyze production systems. Through techniques such as time studies and process mapping, they identify bottlenecks within the system, ensuring that the flow of materials and information is as seamless as possible. By implementing lean manufacturing principles, they aim to eliminate any non-value-added activities, which contributes significantly to reducing waste. In striving for these optimizations, they play a vital role in not only improving output but also in promoting environmentally friendly practices that align with sustainability goals.

Quality assurance is another critical aspect of an industrial engineer’s role. By establishing and monitoring quality control standards, they ensure that products meet specific requirements and customer expectations. This focus on quality minimizes defects and rework, which are both wasteful and resource-intensive. Therefore, effective quality assurance directly correlates to a more sustainable manufacturing process by conserving materials and energy that would otherwise be expended on fixing errors.

Moreover, industrial engineers are involved in designing ergonomic workplaces that enhance worker efficiency and safety. By promoting a culture of continuous improvement, they encourage the adoption of innovative technologies and practices that can further reduce environmental impact. Ultimately, the multifaceted role of industrial engineers is pivotal in steering the manufacturing industry towards greater sustainability, aligning operational efficiency with ecological responsibility.

Sustainable Manufacturing Principles and Practices

Sustainable manufacturing is a strategic approach that emphasizes the need to reduce negative environmental impacts while enhancing social responsibility and economic performance. At the core of sustainable manufacturing lie three primary principles: resource efficiency, waste reduction, and the circular economy. Industrial engineers play a pivotal role in operationalizing these principles through innovative practices.

One of the main focuses of sustainable manufacturing is resource efficiency, which entails maximizing the use of resources such as raw materials, energy, and water. By conducting detailed analyses and employing tools like life cycle assessments, industrial engineers identify avenues for improving production processes and minimizing waste. This can involve upgrading machinery to more energy-efficient alternatives, thereby not only conserving valuable resources but also reducing operational costs.

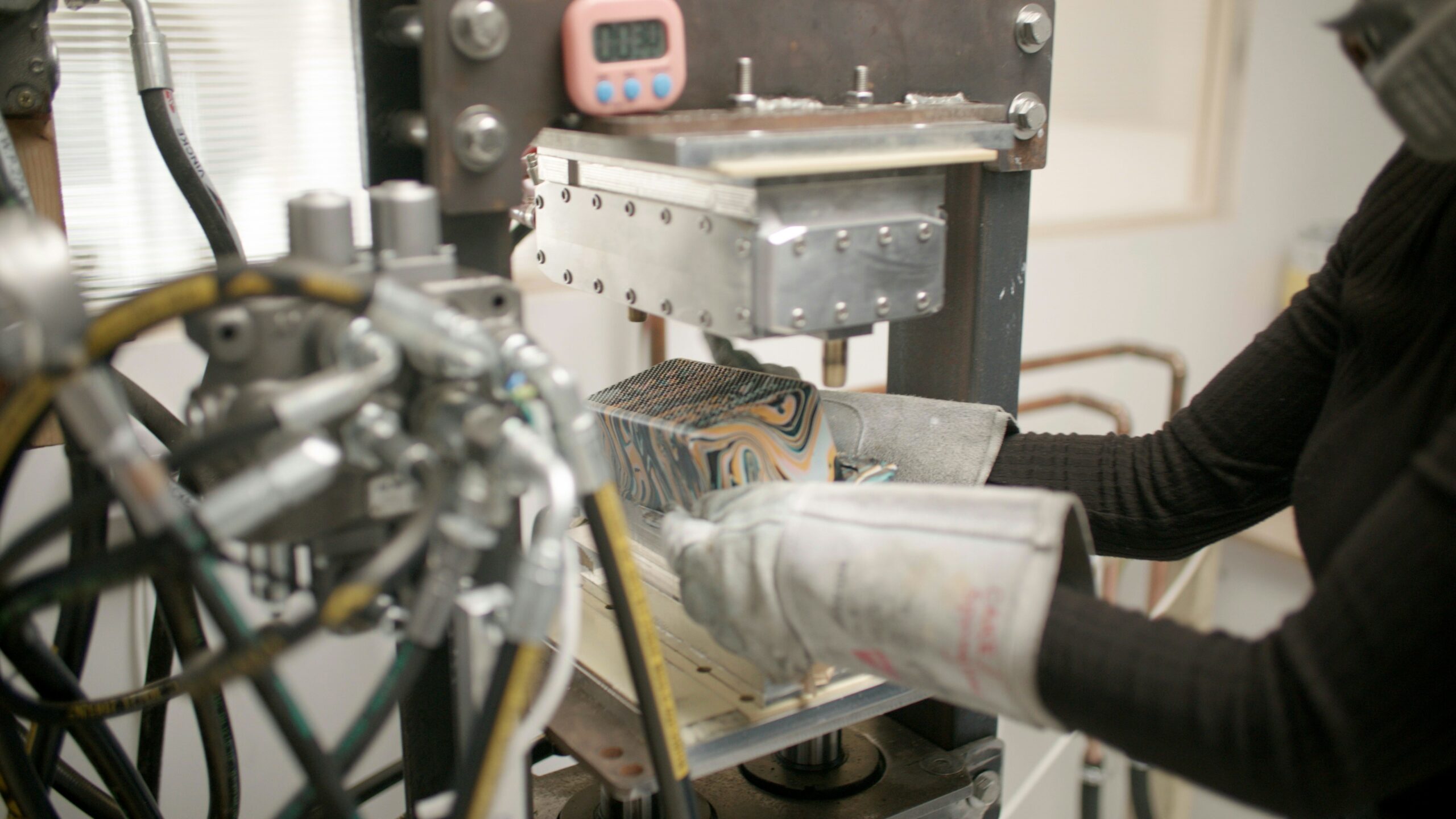

Another critical aspect is waste reduction. Industrial engineers implement practices such as lean manufacturing, which targets the identification and elimination of non-value-added activities throughout the production process. The principles of lean manufacturing encourage companies to adopt a ‘just-in-time’ approach, which helps in managing inventory levels and reducing excess, thereby decreasing waste. By fostering a culture of continuous improvement and problem-solving, industrial engineers encourage teams to assess ongoing processes and implement changes that lead to more sustainable outcomes.

Furthermore, the incorporation of sustainable materials in manufacturing is gaining traction. This includes the use of recycled content, biodegradable materials, and resources sourced from sustainable suppliers. Industrial engineers are instrumental in redesigning product life cycles to include these materials, ultimately contributing to a reduction in ecological footprints. Together, these sustainable practices can be seamlessly integrated into everyday manufacturing processes, leading to a significant improvement in overall sustainability.

Innovative Technologies and Tools Used by Industrial Engineers

Industrial engineers are at the forefront of embracing innovative technologies that are pivotal in promoting sustainability within manufacturing processes. A key area of focus is automation, which streamlines production by reducing waste and enhancing efficiency. By implementing robotics and automated systems, industrial engineers can optimize production timelines and minimize the energy consumed during manufacturing. This automation not only speeds up processes but also lowers the environmental impact by ensuring consistent quality and reducing the reliance on manual labor, which often leads to variability and waste.

Moreover, the integration of artificial intelligence (AI) offers tremendous potential in sustainability initiatives. AI algorithms can analyze vast amounts of data in real-time, identifying patterns that lead to inefficiencies. By leveraging predictive analytics, industrial engineers can foresee equipment failures before they occur, allowing for proactive maintenance that reduces downtime and resource wastage. Consequently, these technologies contribute to a more sustainable manufacturing environment by extending machinery life and lowering operational costs.

The Internet of Things (IoT) represents another innovative tool transformed by industrial engineers. IoT devices facilitate continuous monitoring of equipment and resources, generating data that aids in better decision-making. By utilizing connected sensors, engineers can track energy usage, emissions, and material consumption, thus identifying areas for improvement. Such real-time insights enable organizations to implement targeted strategies that enhance sustainability efforts and reduce their carbon footprint.

Data analytics also plays a crucial role in sustainability initiatives. Industrial engineers harness advanced analytical tools to assess the environmental impact of manufacturing processes. They can evaluate resource usage, lifecycle analysis, and supply chain efficiency, ultimately guiding companies in making informed decisions towards sustainable practices. By focusing on these innovative technologies and tools, industrial engineers significantly contribute to achieving a more sustainable manufacturing landscape.

Case Studies: Successful Sustainability Initiatives

Industrial engineers play a pivotal role in promoting sustainability within manufacturing sectors, as evidenced by several noteworthy case studies. One compelling example is Toyota Motor Corporation, which sought to minimize waste through its renowned Toyota Production System (TPS). This initiative emphasizes lean manufacturing principles, reducing unnecessary processes and materials. By implementing value stream mapping and continuous improvement practices, Toyota reduced its manufacturing waste by over 90%. The challenges faced included cultural resistance to change and the necessity of extensive employee training, yet these hurdles were overcome, resulting in substantial cost savings and a reduced environmental footprint.

Another illustrative case is the approach adopted by Unilever in its pursuit of sustainable sourcing. Unilever established its Sustainable Living Plan, aimed at decreasing its environmental impact while enhancing social conditions in its supply chain. Industrial engineers at Unilever utilized lifecycle assessments to evaluate the environmental consequences of their products, leading to initiatives such as the shift to biodegradable packaging and sourcing palm oil from sustainable producers. Despite initial resistance from suppliers and the complexities of restructuring established operations, the successful implementation of these strategies ultimately enabled Unilever to reduce greenhouse gas emissions from its manufacturing processes by 52% over a five-year period.

A third example can be drawn from General Electric (GE), where the introduction of eco-design principles has significantly influenced its manufacturing procedures. GE focused on integrating sustainable practices into the early phases of product development. This strategic shift not only resulted in energy-efficient appliances but also allowed the company to meet increasing consumer demand for environmentally-friendly products. The challenges faced included balancing short-term economic pressures with long-term sustainability goals, yet the initiative led to a 30% decrease in energy consumption across its product lines.

Through these case studies, it is evident that industrial engineers are essential in transforming manufacturing practices towards sustainability. They employ innovative strategies, face various challenges, and ultimately achieve remarkable outcomes that benefit both the environment and the companies’ bottom lines.

Collaboration Across Disciplines for Enhanced Sustainability

The drive towards sustainability in manufacturing necessitates a multifaceted approach characterized by collaborative efforts across various disciplines. Industrial engineers, in particular, play a pivotal role in this integration by working alongside environmental scientists, supply chain managers, and other stakeholders. Their involvement ensures that sustainability is not treated as a standalone initiative but rather as an integral part of the manufacturing process.

Interdisciplinary collaboration fosters a comprehensive understanding of sustainability challenges. For instance, environmental scientists bring expertise in ecological impacts and resources conservation, highlighting the importance of adhering to environmental regulations and best practices. By teaming up with these experts, industrial engineers can design processes that minimize waste and energy consumption, yielding both economic and environmental benefits. This synergetic relationship enables the development of innovative solutions that are technically sound and environmentally responsible.

Moreover, industrial engineers collaborate closely with supply chain managers to enhance the sustainability of processes from raw material extraction to product delivery. This partnership allows for the implementation of strategies that reduce the carbon footprint across the supply chain. By leveraging data analytics, industrial engineers can identify inefficiencies, streamline operations, and, ultimately, reduce unnecessary resource consumption. Such efforts not only support the aim of achieving sustainability but also enhance overall operational performance.

The blend of perspectives from different disciplines is crucial for addressing the complexities associated with sustainability in manufacturing. This collaborative model encourages the sharing of knowledge and best practices, leading to more effective and innovative solutions. As industrial engineers continue to champion interdisciplinary approaches, the industry’s collective capacity to face sustainability challenges will intensify, paving the way for a more sustainable future in manufacturing.

Regulations and Standards Impacting Sustainable Manufacturing

The landscape of sustainable manufacturing is significantly shaped by a variety of regulations and standards aimed at promoting environmentally responsible practices. Industrial engineers play a crucial role in navigating these frameworks, ensuring compliance while advancing sustainability initiatives. Understanding both international and local regulations is vital for manufacturers aiming to align their production processes with sustainability goals.

Internationally recognized standards, such as ISO 14001, provide a systematic approach for organizations to enhance their environmental performance. This standard sets the criteria for an effective environmental management system (EMS), enabling manufacturers to assess and mitigate their ecological impact. By integrating such standards into their operations, industrial engineers can help establish protocols that not only comply with legal requirements but also foster sustainable innovation.

In addition to international standards, government regulations also dictate the boundaries within which manufacturers operate. Policies aimed at reducing carbon emissions and waste production are becoming increasingly stringent, demanding that companies adapt their processes to minimize environmental harm. For example, regulations might require manufacturers to report their greenhouse gas emissions or adhere to specific waste management practices. Industrial engineers must be adept at interpreting these regulations to develop strategies that ensure compliance while maintaining operational efficiency.

Furthermore, industry-specific guidelines often inform best practices for sustainability. For instance, in the automotive sector, standards focused on reducing material waste and enhancing energy efficiency are prevalent. Industrial engineers, with their analytical skills and process optimization expertise, are uniquely positioned to integrate these guidelines into the production workflow, thus driving forward the agenda of sustainable manufacturing.

In conclusion, the interplay of international standards, governmental regulations, and industry guidelines significantly influences sustainable manufacturing practices. Industrial engineers are essential in this context, as they strategically navigate these frameworks to enhance compliance and promote innovation in sustainability efforts within the manufacturing sector.

Future Trends in Industrial Engineering and Sustainability

As we move forward, the intersection of industrial engineering and sustainability will become increasingly impactful in the manufacturing landscape. One prominent trend is the adoption of circular economy practices, which emphasize reuse, recycling, and the reduction of waste. Industrial engineers play a crucial role in designing systems that are not only efficient but also capable of minimizing waste through innovative processes. This approach promotes sustainability by ensuring resources are used productively, thus enhancing the overall lifecycle of products.

In addition to circular economy practices, advances in green technology are reshaping manufacturing processes. Innovations such as energy-efficient machinery, automation, and renewable energy sources are becoming integral to industrial engineering. Engineers must adapt to these technological advancements to integrate sustainability into their designs effectively. This also includes the implementation of smart manufacturing systems that utilize data analytics and IoT technologies to optimize resource use and reduce environmental impact.

Shifts in consumer behavior also significantly contribute to the future of industrial engineering. Modern consumers are more environmentally conscious, preferring products that are sustainably produced. This increased demand for sustainable manufacturing necessitates a proactive approach from industrial engineers, who must develop processes that align with these evolving consumer expectations. Understanding market trends and consumer preferences will be vital for engineers to take effective action in promoting sustainable practices.

To stay ahead of these trends, industrial engineers need to engage in continuous learning and adaptation. This can involve attending industry conferences, participating in professional development courses, and networking with peers who are also focused on sustainability. By remaining informed and proactive, industrial engineers can drive significant contributions to sustainable manufacturing, ensuring that their projects meet contemporary societal and environmental demands.

Conclusion and Call to Action

Industrial engineers are uniquely positioned at the intersection of efficiency and sustainability within the manufacturing sector. Throughout this discussion, we have explored how these professionals utilize their expertise in systems optimization, process improvement, and resource management to drive sustainable practices. By integrating principles of sustainability into their workflows, industrial engineers contribute significantly to reducing waste, lowering energy consumption, and minimizing environmental impact.

The crucial role of industrial engineers in fostering a culture of sustainability cannot be overstated. Their analytical skills enable them to assess operational processes critically and implement innovative solutions that enhance both productivity and compliance with environmental standards. As businesses increasingly recognize the importance of sustainable practices, industrial engineers must take the lead in developing strategies that not only bolster efficiency but also prioritize ecological stewardship.

As we conclude, it is essential to encourage industry professionals to adopt and champion sustainable practices in their manufacturing processes. Engaging with stakeholders to share insights, best practices, and lessons learned can foster collaboration and inspire action within the broader manufacturing community. By emphasizing the importance of sustainability, industrial engineers can help shape a future where manufacturing operations support economic viability while protecting the planet.

We invite you to participate in these discussions. Share your experiences related to sustainability initiatives in manufacturing, whether through challenges faced or successes achieved. By coming together to learn and grow, we can collectively drive meaningful change and establish a more sustainable manufacturing landscape for generations to come.