Transitioning from Industry 4.0 to Industry 5.0: What It Means for Engineers

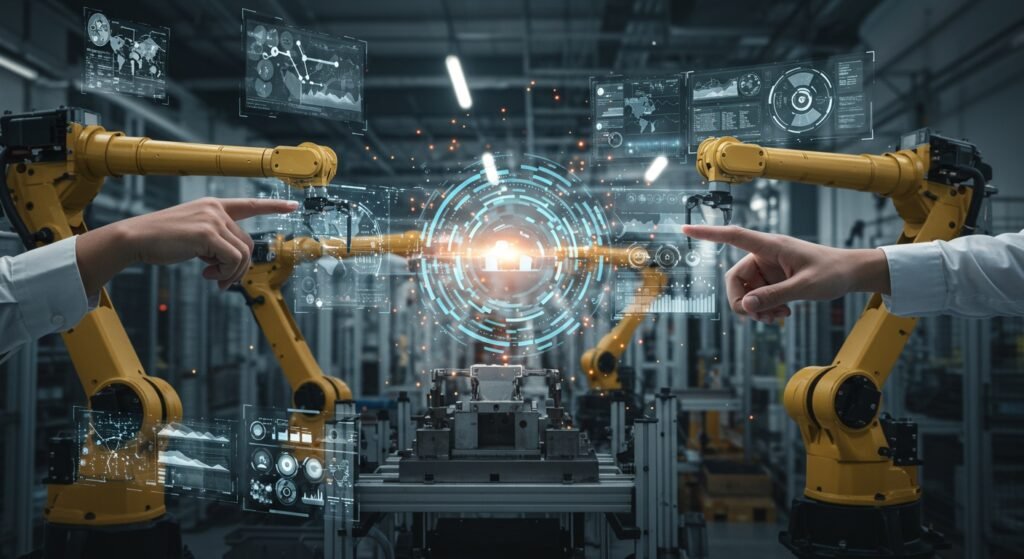

The industrial landscape is perpetually evolving, constantly pushing the boundaries of technology and human capability. We’ve witnessed the profound impact of Industry 4.0, characterized by automation, data exchange, and smart factories. But now, a new paradigm is emerging: Industry 5.0. This next phase isn’t just about efficiency or productivity; it’s about re-centering humanity in the manufacturing process, emphasizing collaboration between humans and machines, resilience, and sustainability. For engineers, this transition is not merely a technological upgrade but a fundamental shift in mindset and skill set. Understanding what Industry 5.0 entails is crucial for those who will shape its future.

Table of Contents

- Understanding the Leap: From Industry 4.0 to Industry 5.0

- Key Pillars of Industry 5.0

- What Industry 5.0 Means for Engineers: A Practical Outlook

- Challenges and Opportunities in the Industry 5.0 Era

Understanding the Leap: From Industry 4.0 to Industry 5.0

To appreciate the significance of Industry 5.0, it’s essential to first grasp the foundations laid by its predecessor.

The Core Principles of Industry 4.0

Industry 4.0 brought us the smart factory, where cyber-physical systems, the Internet of Things (IoT), and artificial intelligence (AI) created highly automated and data-driven production environments. Its primary goals were increased efficiency, optimized production, and mass customization, often through minimizing human intervention in repetitive or dangerous tasks.

Defining Industry 5.0: Beyond Efficiency

While Industry 4.0 focused on connecting machines and systems, Industry 5.0 takes a crucial step further by reconnecting technology with human ingenuity. It’s a vision of industry that recognizes the power of collaboration between humans and robots (cobots), valuing human creativity, critical thinking, and problem-solving skills alongside the precision and endurance of machines. It adds a layer of human-centricity, sustainability, and resilience to the technological advancements of Industry 4.0, aiming for a more ethical and societal impact.

Key Pillars of Industry 5.0

This new industrial revolution rests on three fundamental pillars:

Human-Centricity and Collaboration

At its heart, Industry 5.0 champions the symbiotic relationship between humans and advanced technologies. It’s about designing systems where robots assist humans, augmenting their capabilities rather than replacing them. This means engineers will focus on creating intuitive human-machine interfaces, ensuring safety in collaborative environments, and empowering workers with new tools and data to make informed decisions.

Resilience and Sustainability

The lessons from global disruptions have highlighted the need for industrial resilience. Industry 5.0 aims to build robust supply chains and production systems capable of withstanding unexpected shocks. Simultaneously, it places a strong emphasis on environmental sustainability, promoting circular economy principles, energy efficiency, and waste reduction throughout the entire product lifecycle. This shift requires engineers to innovate with sustainable materials and processes.

Customization and Personalization

Moving beyond mass customization, Industry 5.0 enables highly personalized products and services at an industrial scale. This demands flexible manufacturing systems and advanced data analytics to understand individual customer needs and deliver bespoke solutions efficiently.

What Industry 5.0 Means for Engineers: A Practical Outlook

For engineers, the transition to Industry 5.0 is transformative. It calls for a broader skill set that combines technical prowess with soft skills and ethical considerations. Automation remains important, but the focus shifts to how automation enhances human work rather than replacing it.

| Industry 4.0 Engineer Skills | Industry 5.0 Engineer Skills |

|---|---|

| Data Analytics, IoT Integration | Human-Robot Interaction (HRI), Ethical AI, Data Storytelling |

| Automation, Predictive Maintenance | Collaborative Robotics, Resilience Engineering, Sustainable Design |

| Cybersecurity, Cloud Computing | Advanced Materials, Digital Twin for Human Augmentation, Circular Economy Principles |

| System Optimization | Systems Thinking, Interdisciplinary Collaboration, Creative Problem-Solving |

Engineers will need to become adept at designing human-friendly manufacturing processes, developing AI that augments human intelligence, and integrating sustainable practices into every stage of production. For instance, understanding advanced robotics and how they interact with human operators will be paramount. Read more about advanced robotics in manufacturing on our site.

Moreover, the ethical implications of AI and human-machine collaboration will demand careful consideration, pushing engineers to factor societal impact into their designs. Resources like those from UNEP provide valuable insights into sustainable manufacturing practices that will become integral to engineering roles.

Challenges and Opportunities in the Industry 5.0 Era

The path to Industry 5.0 is not without its hurdles. Up-skilling the existing workforce, ensuring data privacy and security in collaborative environments, and overcoming initial investment costs are significant challenges. However, the opportunities are even greater: creating more meaningful and safer jobs, fostering innovation, developing truly sustainable industrial practices, and building a more resilient global economy. Engineers are at the forefront of tackling these challenges and harnessing these opportunities.

Conclusion

The shift to Industry 5.0 represents a monumental evolution in how we conceive and execute manufacturing. It’s a move away from purely technological advancement towards a more holistic approach that values human input, environmental responsibility, and societal well-being. For engineers, this means an exciting future filled with new responsibilities, innovative challenges, and the chance to contribute to an industrial landscape that is not only efficient but also deeply human-centric, resilient, and sustainable. Embrace the change, for the future of engineering is collaborative, ethical, and profoundly impactful.