Integrating Robotics and AI for Zero-Downtime Production

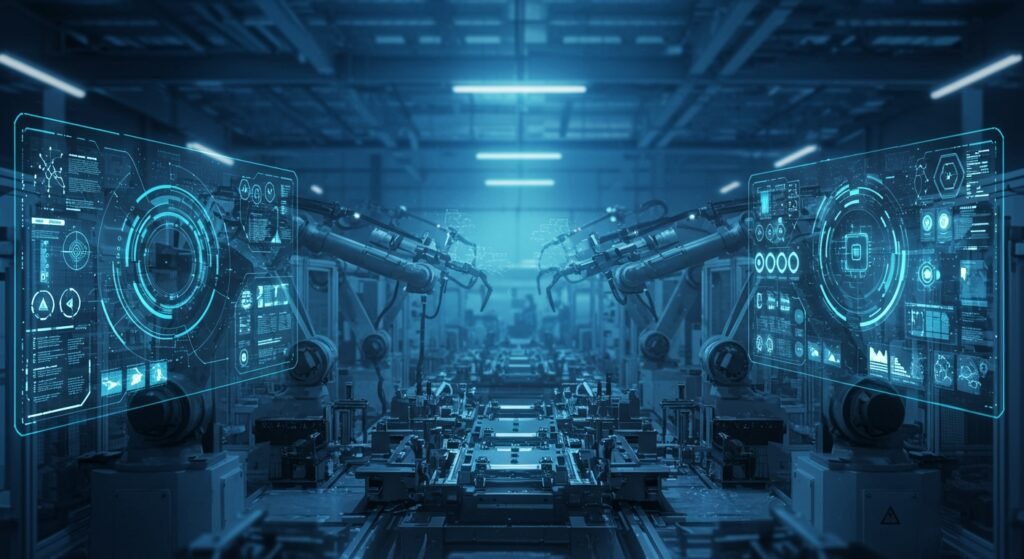

In the relentless pursuit of operational excellence, modern manufacturing faces an ever-present adversary: downtime. Every minute a production line stands still translates into lost revenue, delayed deliveries, and diminished competitiveness. The transformative answer lies in the powerful combination of artificial intelligence (AI) and advanced robotics automation, charting a course towards the coveted goal of zero-downtime production. By leveraging intelligent machines that can learn, adapt, and predict, industries are moving beyond reactive maintenance to proactive, uninterrupted manufacturing cycles.

Table of Contents

- The Synergy of Robotics and AI

- Key Benefits of AI-Powered Robotics Automation

- Implementing Zero-Downtime Production

- Challenges and Solutions

- The Future of Manufacturing

The Synergy of Robotics and AI

Traditionally, industrial robots have been programmed to perform repetitive tasks with high precision. While efficient, their operations were often rigid and required human intervention for complex adjustments or anomaly detection. The integration of AI transforms these machines from mere automatons into intelligent collaborators. AI algorithms enable robots to perceive their environment, make real-time decisions, learn from experience, and even communicate with other systems.

This synergy means robots can adapt to variations in materials, adjust their movements for optimal efficiency, and self-diagnose potential issues. For example, an AI-powered robotic arm can detect a slight deviation in a weld seam, immediately correct its trajectory, and alert maintenance about potential wear on its nozzle – all without halting the production line. This continuous feedback loop is fundamental to achieving zero downtime.

Key Benefits of AI-Powered Robotics Automation

The convergence of AI and robotics automation unlocks a spectrum of advantages that redefine operational efficiency and reliability in manufacturing.

Predictive Maintenance

One of the most significant contributions of AI to zero-downtime production is predictive maintenance. AI systems analyze vast amounts of sensor data – temperature, vibration, current draw, acoustic signatures – from robotic equipment. By identifying subtle patterns that precede equipment failure, AI can accurately predict when a component is likely to fail. This allows maintenance teams to schedule interventions precisely when needed, during planned downtimes or without stopping operations entirely, thereby preventing unexpected breakdowns. For deeper insights into advanced maintenance strategies, consider exploring IndustryWeek’s articles on predictive maintenance.

Real-time Optimization

AI enables robots to dynamically optimize their performance. This includes adjusting speed, path planning, and force application based on live data from the production line. If a bottleneck is detected upstream, AI can re-route parts or adjust downstream processes to maintain flow. This adaptability ensures maximum throughput and minimizes idle time, responding instantaneously to changes that would typically cause significant delays in traditional setups.

Enhanced Quality Control

AI-powered vision systems integrated with robotic arms can perform inspections with accuracy and speed far beyond human capabilities. They can detect microscopic defects, verify assembly, and ensure product quality at every stage. If a recurring defect pattern is identified, the AI can trace it back to its source, whether it’s a specific robot, tool, or material batch, allowing for immediate corrective action without pausing the entire line.

Implementing Zero-Downtime Production

Achieving zero-downtime production with AI and robotics is a strategic journey, not a single step. It requires careful planning and execution:

- Data Infrastructure: Establish robust data collection systems across all production assets. High-quality data is the fuel for AI.

- AI Model Development: Train AI models using historical and real-time data to recognize operational patterns, predict failures, and suggest optimizations.

- Seamless Integration: Integrate AI insights directly into robotic control systems, allowing for autonomous adjustments and decision-making.

- Continuous Learning: Implement a feedback loop where AI models continuously learn from new data, refining their predictions and optimizations over time.

- Human-Robot Collaboration: Empower human operators with AI-driven insights, enabling them to make better-informed decisions and manage exceptions.

These steps contribute to building a resilient, intelligent manufacturing ecosystem. For more insights into creating a truly connected ecosystem, explore our guide on Smart Factory Implementation.

| Feature | Traditional Production | AI-Driven Robotics Production |

|---|---|---|

| Maintenance | Reactive, Scheduled | Predictive, Proactive |

| Flexibility | Rigid, Manual Reconfiguration | Adaptive, Autonomous Optimization |

| Error Detection | Human-reliant, Post-production | Real-time, AI Vision Systems |

| Downtime Frequency | High, Unpredictable | Low, Minimally Planned |

| Efficiency | Static, Prone to Bottlenecks | Dynamic, Continuously Optimized |

Challenges and Solutions

While the benefits are profound, implementing AI and robotics automation for zero-downtime isn’t without its hurdles. Initial investment costs, the complexity of integration, and the need for specialized skills are significant. Data security and privacy are also paramount concerns. Solutions include phased implementation strategies, leveraging cloud-based AI services to reduce upfront costs, and investing in workforce training to bridge skill gaps. Collaboration with technology providers and adopting industry standards can also streamline the process and enhance security.

The Future of Manufacturing

The vision of manufacturing operating 24/7 with minimal human intervention due to unexpected stoppages is rapidly becoming a reality. The ongoing advancements in AI and robotics are paving the way for truly autonomous factories where machines not only perform tasks but also manage, maintain, and optimize themselves. This continuous improvement paradigm will not only boost productivity but also free human workers from monotonous tasks, allowing them to focus on innovation, strategic planning, and managing the sophisticated AI systems. Zero-downtime production, powered by the seamless integration of AI and robotics, is not just an aspiration; it is the next frontier for competitive manufacturing.