Predictive Maintenance for Manufacturing Sustainability

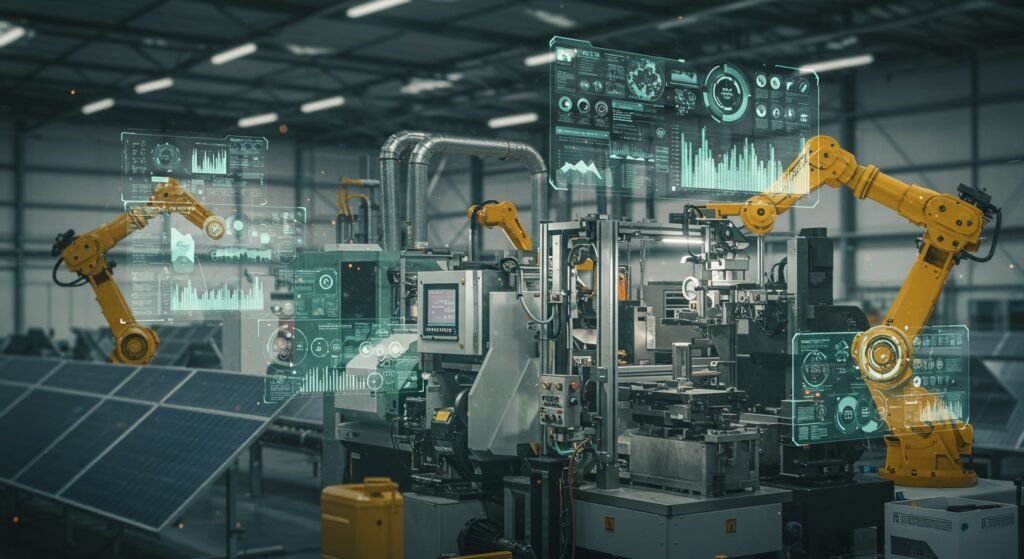

In an era where environmental responsibility is paramount, manufacturers are under increasing pressure to adopt greener practices. One of the most impactful strategies gaining traction is sustainable maintenance, specifically through the implementation of predictive maintenance technologies. This approach not only extends the lifespan of machinery and prevents costly downtime but also plays a pivotal role in significantly reducing resource consumption and environmental footprint. By leveraging data and advanced analytics, companies can transition from reactive and time-based maintenance to a more efficient, proactive system that champions ecological stewardship. This article explores how predictive maintenance revolutionizes manufacturing sustainability, driving both operational excellence and environmental gains.

Table of Contents

- Introduction to Sustainable Maintenance

- What is Predictive Maintenance?

- Predictive Maintenance and Sustainable Operations

- Key Benefits of Sustainable Maintenance in Manufacturing

- Implementing Predictive Maintenance for Green Operations

- Challenges and Solutions

- The Future of Sustainable Maintenance

- Conclusion

Introduction to Sustainable Maintenance

The concept of sustainable maintenance is rooted in the broader objective of sustainable manufacturing, which aims to create products using processes that minimize negative environmental impacts, conserve energy and natural resources, are safe for employees, communities, and consumers, and are economically sound. Traditional maintenance methods often contribute to waste through premature part replacement, inefficient energy use due to poorly performing machinery, and unnecessary travel for inspections. Predictive maintenance, by contrast, offers a sophisticated solution to these challenges, aligning operational goals with environmental responsibility.

What is Predictive Maintenance?

Predictive Maintenance (PdM) is a technique that uses data analysis tools and techniques to detect anomalies in equipment operation and potential defects so that they can be addressed before they lead to equipment failure. Unlike preventive maintenance, which schedules maintenance at fixed intervals, PdM schedules maintenance only when it is needed, based on the actual condition of the equipment. This is achieved through continuous monitoring using sensors that collect data on vibration, temperature, oil levels, acoustics, and other performance indicators. Artificial intelligence (AI) and machine learning (ML) algorithms then analyze this data to predict when maintenance will be required, allowing for precise, just-in-time interventions.

Predictive Maintenance and Sustainable Operations

The link between predictive maintenance and sustainability is profound. By optimizing asset performance and longevity, PdM directly contributes to several pillars of green operations.

Boosting Energy Efficiency

Malfunctioning or poorly maintained machinery consumes more energy. For instance, a bearing with increased friction or a motor running outside its optimal parameters will draw excessive power. Predictive maintenance identifies these inefficiencies early, allowing for timely repairs that restore equipment to peak operational efficiency. This proactive approach significantly reduces overall energy consumption in manufacturing processes, leading to lower utility bills and a smaller carbon footprint. The ability of predictive AI to fine-tune operations means less wasted energy on the factory floor.

Minimizing Waste and Resource Consumption

A core tenet of sustainable maintenance is waste reduction. Traditional maintenance often involves replacing parts on a fixed schedule, even if they still have operational life, leading to unnecessary material waste. Catastrophic failures, prevented by PdM, can also result in extensive damage to surrounding components and require the disposal of large, complex assemblies. By accurately predicting component lifespan and failure points, PdM ensures parts are replaced only when truly necessary, minimizing scrap, reducing raw material consumption, and lessening the burden on landfills. This approach is critical for advancing a circular economy within manufacturing.

Consider the impact of different maintenance strategies on waste:

| Maintenance Strategy | Impact on Parts Waste | Impact on Energy Waste | Impact on Downtime |

|---|---|---|---|

| Reactive (Breakdown) | High (catastrophic failures, secondary damage) | High (inefficient operation before failure) | Very High (unplanned, long) |

| Preventive (Time-based) | Medium (premature replacement of healthy parts) | Medium (minor inefficiencies persist until scheduled) | Medium (planned, but frequent) |

| Predictive (Condition-based) | Low (parts replaced only when needed) | Low (optimized operation, early fault detection) | Low (planned, minimized) |

Reducing Emissions and Environmental Impact

Beyond energy and material waste, predictive maintenance contributes to lower emissions. Optimized machinery that runs efficiently uses less energy, which directly translates to reduced greenhouse gas emissions, especially in facilities relying on fossil fuel-derived electricity. Furthermore, by preventing breakdowns, PdM reduces the need for emergency repairs that might involve expedited shipping of parts (increasing transportation emissions) or the use of energy-intensive manufacturing processes to quickly produce replacements.

Key Benefits of Sustainable Maintenance in Manufacturing

The adoption of sustainable maintenance via predictive technologies offers a multitude of benefits:

- Extended Asset Lifespan: By addressing minor issues before they escalate, machinery lasts longer, reducing capital expenditure and the environmental cost of manufacturing new equipment.

- Improved Operational Efficiency: Minimized unplanned downtime and optimized performance lead to smoother production schedules and higher output. This aligns with broader goals of optimizing manufacturing efficiency.

- Enhanced Safety: Fewer sudden equipment failures mean a safer working environment for employees.

- Cost Savings: Significant reductions in energy consumption, spare parts inventory, and labor costs associated with reactive repairs.

- Reputation Boost: Demonstrating a commitment to sustainability enhances a company’s brand image and appeal to environmentally conscious consumers and investors.

Implementing Predictive Maintenance for Green Operations

Transitioning to predictive maintenance requires strategic planning:

- Pilot Projects: Start with critical assets where failures are costly and environmentally impactful.

- Data Infrastructure: Invest in sensors, IoT devices, and a robust data collection and storage system.

- Analytics Platform: Deploy AI and machine learning tools capable of processing sensor data and generating actionable insights.

- Skilled Workforce: Train existing staff or hire new talent with expertise in data science, industrial IoT, and analytics.

- Integration: Ensure seamless integration with existing enterprise resource planning (ERP) and maintenance management systems (CMMS). For more insights into industrial sustainability, you might consult resources like this industrial sustainability report.

Challenges and Solutions

While the benefits are clear, implementing PdM for sustainability can face hurdles such as the initial investment in technology, data security concerns, and the need for new skill sets. These can be overcome through phased implementation, partnering with technology providers, and investing in continuous training programs. The long-term environmental and economic returns typically outweigh these upfront challenges.

The Future of Sustainable Maintenance

The future of sustainable maintenance is inextricably linked with advancements in AI, machine learning, and the Industrial Internet of Things (IIoT). We can expect even more sophisticated predictive models, prescriptive analytics that recommend specific actions, and eventually, fully autonomous maintenance systems. Digital twins will play a crucial role, allowing manufacturers to simulate various scenarios and optimize maintenance strategies without disrupting physical operations. This evolution will further cement manufacturing’s commitment to a greener planet.

Conclusion

Predictive maintenance is no longer just a buzzword for operational efficiency; it is a cornerstone of manufacturing sustainability. By intelligently monitoring equipment, anticipating failures, and optimizing resource use, companies can dramatically reduce their environmental footprint while simultaneously boosting profitability and resilience. Embracing sustainable maintenance through predictive technologies is a strategic imperative for any forward-thinking manufacturer aiming to thrive in a greener, more responsible industrial landscape.