Process Optimization with Simulation: Your Guide to Unlocking Efficiency

In today’s fast-paced industrial and business landscape, achieving peak operational efficiency is no longer a luxury but a necessity. This is where Process Optimization with Simulation steps in, offering a powerful methodology to analyze, predict, and enhance complex systems without real-world disruption. By creating virtual models of processes, organizations can experiment with different scenarios, identify bottlenecks, and make data-driven decisions that lead to significant improvements in performance, cost, and quality. This article will delve into the core concepts, benefits, and practical applications of process simulation, providing a comprehensive overview for anyone looking to revolutionize their operations.

Table of Contents

- What is Process Optimization with Simulation?

- Benefits of Implementing Simulation for Process Optimization

- Industries Benefiting from Process Simulation

- Steps to Effective Process Optimization with Simulation

- Future Trends in Process Optimization

- Conclusion

What is Process Optimization with Simulation?

Process Optimization with Simulation involves building a computer model of an existing or proposed process to understand its behavior and test potential improvements. This virtual environment allows for the replication of real-world conditions, including resource allocation, task sequencing, and variability, providing insights that might be impossible or too costly to gain otherwise. It’s a critical tool for industrial engineering and management science.

Key Principles of Simulation

At its heart, simulation relies on a few fundamental principles:

- Modeling Reality: Capturing the essential elements and interactions of a system in a digital format.

- Experimentation: Running the model under various conditions to observe outcomes.

- Analysis: Interpreting the simulation results to identify areas for improvement, predict performance, and validate decisions.

This iterative process allows for continuous refinement and a deep understanding of process dynamics.

Benefits of Implementing Simulation for Process Optimization

The advantages of using simulation for process improvement are numerous and profound, impacting everything from bottom-line costs to strategic decision-making.

Enhanced Decision Making

Simulation provides a risk-free environment to test ‘what-if’ scenarios. Managers can evaluate the impact of different resource levels, scheduling strategies, or technology investments before committing real resources. This leads to more informed and confident decisions, reducing the likelihood of costly errors.

Risk Mitigation and Cost Savings

By identifying potential bottlenecks, resource contention, and operational inefficiencies within the virtual model, organizations can mitigate risks before they manifest in the physical world. This proactive approach saves significant costs associated with rework, delays, and underperforming systems.

Industries Benefiting from Process Simulation

While often associated with manufacturing, process simulation’s utility extends across a vast array of sectors.

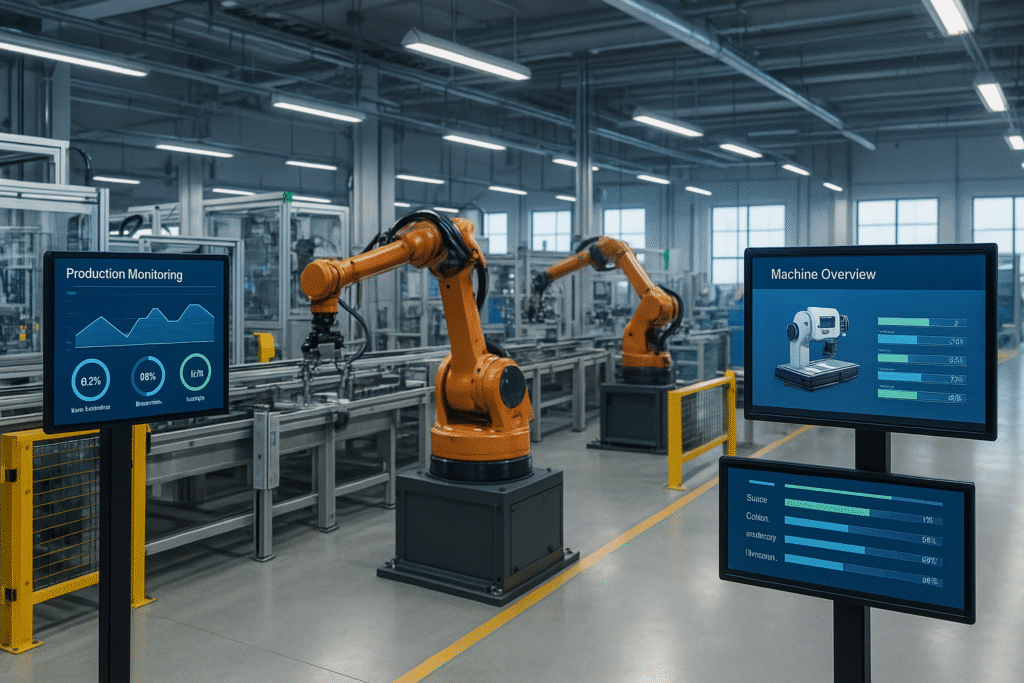

Manufacturing and Logistics

In manufacturing, simulation is used to optimize production lines, plant layouts, inventory levels, and supply chain logistics. It helps in balancing workloads, reducing lead times, and improving throughput. For logistics, it can model warehouse operations, fleet management, and delivery routes to enhance efficiency.

Healthcare and Service Industries

Hospitals use simulation to optimize patient flow, emergency room operations, and surgical scheduling, leading to reduced wait times and better patient care. In service industries, it helps streamline customer service processes, call center operations, and retail store layouts to improve customer experience and operational efficiency.

Steps to Effective Process Optimization with Simulation

Implementing a successful simulation project involves a structured approach.

Data Collection and Model Building

The first step is gathering accurate data about the existing process, including timings, resource availability, and variability. This data forms the basis for building a realistic simulation model. The model must accurately represent the system’s logic and behavior.

Experimentation and Analysis

Once the model is built and validated, various scenarios can be tested. This involves changing parameters (e.g., adding resources, altering schedules) and running the simulation multiple times to observe the impact. The results are then analyzed to identify optimal solutions and predict performance improvements.

| Metric | Before Optimization | After Simulation-Based Optimization |

|---|---|---|

| Average Throughput (units/day) | 500 | 650 (+30%) |

| Average Lead Time (days) | 10 | 7 (-30%) |

| Resource Utilization (%) | 60% | 85% (+25%) |

| Cost per Unit | $15 | $12 (-20%) |

Future Trends in Process Optimization

The field of simulation is continually evolving, with advancements in computing power and AI leading to even more sophisticated applications. Expect to see greater integration with real-time data, AI-driven optimization algorithms, and virtual reality interfaces for more immersive analysis. For more on related topics, you might be interested in our article on Industrial Engineering Trends.

As organizations strive for greater agility and resilience, the role of simulation will only grow. It allows for the exploration of complex systems in a safe, controlled, and cost-effective manner. To learn more about modern simulation software, visit AnyLogic Simulation Software.

Conclusion

Process Optimization with Simulation is an indispensable tool for modern businesses aiming to achieve operational excellence. By providing deep insights into process dynamics and enabling risk-free experimentation, it empowers decision-makers to implement changes that drive efficiency, reduce costs, and foster innovation. Embracing this technology is a strategic move towards building a more resilient and competitive organization in any industry.