In today’s complex business landscape, achieving peak operational efficiency is paramount. One of the most powerful tools transforming industries is Process Optimization with Simulation. This advanced methodology allows organizations to model, analyze, and improve their operational processes without disrupting real-world operations, leading to significant gains in productivity, cost savings, and risk mitigation.

Table of Contents

What is Process Optimization with Simulation?

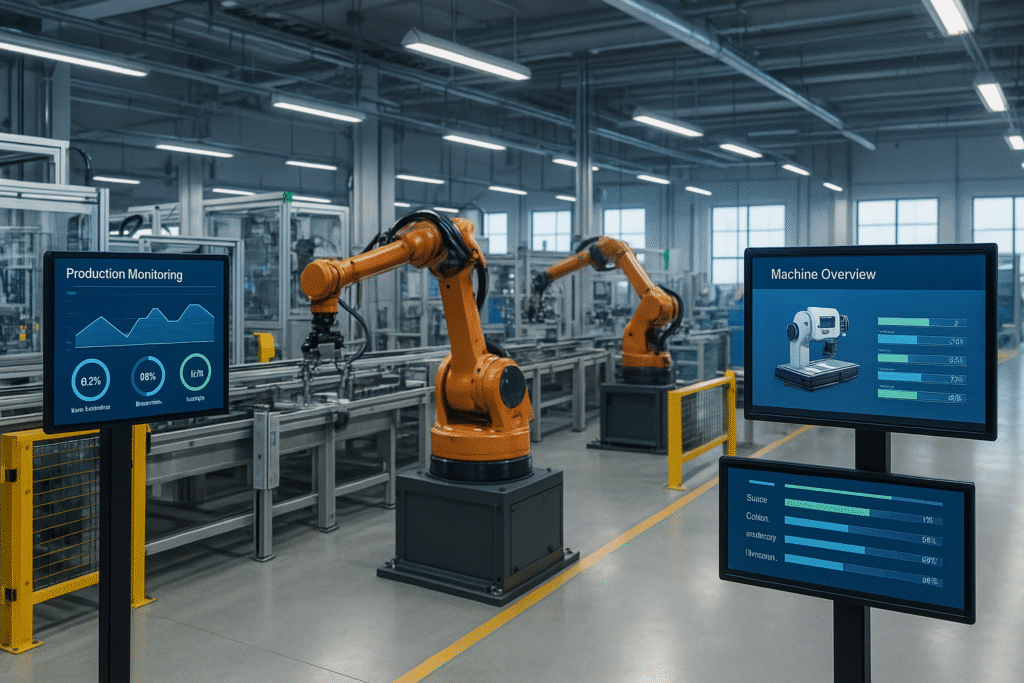

Process Optimization with Simulation involves creating a virtual representation, or model, of a real-world process. This model can be anything from a manufacturing assembly line to a hospital’s patient flow, or even a supply chain network. By running various scenarios within this simulated environment, businesses can test different strategies, identify bottlenecks, and predict outcomes. This allows for ‘what-if’ analysis in a risk-free setting, providing invaluable insights for making informed decisions on process improvements. It’s a critical component of modern industrial engineering, allowing for proactive rather than reactive problem-solving.

Key Benefits of Simulation in Industrial Engineering

The application of simulation in industrial engineering offers a multitude of benefits, driving efficiency and profitability across sectors. These advantages extend beyond mere troubleshooting to strategic planning and long-term resilience.

Enhanced Decision Making

Simulation provides a data-driven approach to decision-making. By visualizing the impact of proposed changes on key performance indicators (KPIs) like throughput, waiting times, and resource utilization, managers can select the optimal path. This reduces reliance on intuition or trial-and-error, leading to more robust and effective process improvements.

Cost Reduction Strategies

Before investing heavily in new equipment, staff, or facility layouts, simulation can predict the return on investment and potential cost savings. It helps identify resource redundancies, optimize scheduling, and minimize waste, directly contributing to a healthier bottom line. For more in-depth technical details on various applications, you can visit the INFORMS website.

How Simulation Works in Practice

Implementing process optimization through simulation typically follows several stages. It begins with defining the problem and collecting data on the current process. Next, a conceptual model is developed, followed by building the simulation model using specialized software. Once built, the model is validated and verified against real-world data to ensure its accuracy. Then, experiments are conducted by changing parameters within the model. The results are analyzed, and recommendations are derived for process improvements. Finally, these improvements are implemented in the real system.

| Industry | Simulation Use Case | Benefit |

|---|---|---|

| Manufacturing | Optimizing production lines, layout planning | Reduced lead times, increased throughput |

| Healthcare | Patient flow analysis, resource allocation | Shorter wait times, better patient care |

| Logistics | Warehouse design, routing optimization | Lower transportation costs, faster delivery |

| Retail | Customer queue management, store layout | Improved customer satisfaction, higher sales |

Future Trends in Simulation for Process Optimization

The field of process simulation is continuously evolving. We’re seeing increased integration with Artificial Intelligence and Machine Learning, allowing models to learn from historical data and make predictive optimizations. The rise of digital twins, which are live, virtual models of physical assets or processes, is also revolutionizing how real-time data informs simulation. This concept is closely related to the emerging field of digital twins, offering unprecedented levels of insight and control. Cloud-based simulation platforms are making this powerful technology more accessible to businesses of all sizes, democratizing advanced optimization techniques.

Conclusion

Process Optimization with Simulation is no longer a niche tool but a fundamental requirement for businesses aiming to thrive in competitive markets. By providing a safe, cost-effective, and insightful way to test and refine processes, it empowers organizations to make smarter decisions, enhance efficiency, and build more resilient operations. Embracing simulation is a strategic imperative for any company committed to continuous improvement and operational excellence.