Table of Contents

- What is Process Optimization with Simulation?

- The Core Benefits of Simulation in Process Improvement

- Key Applications Across Industries

- How Simulation Drives Operational Excellence

- Implementing Simulation for Success

- Conclusion

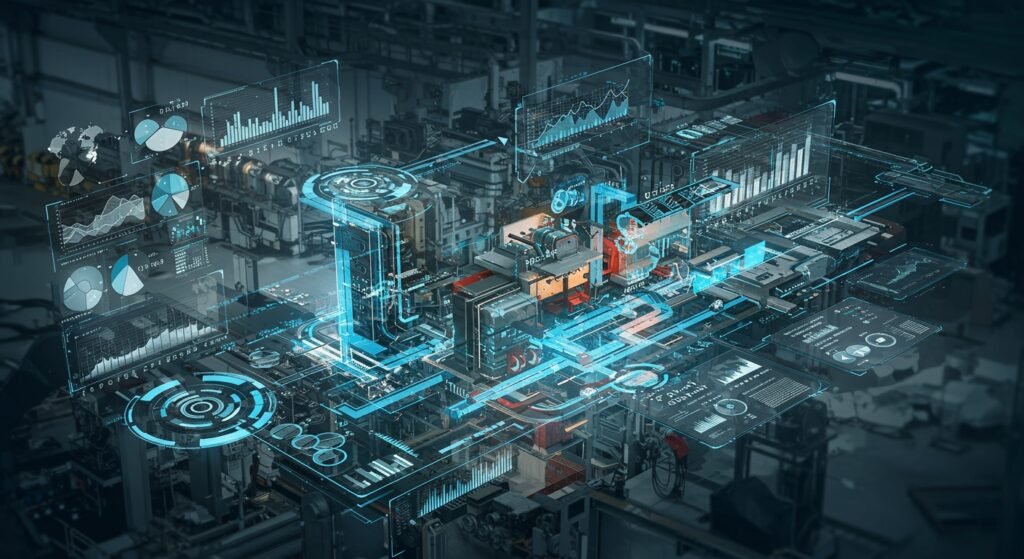

In today’s fiercely competitive industrial landscape, businesses are relentlessly seeking innovative methodologies to gain a significant competitive edge. One of the most transformative approaches emerging is Process Optimization with Simulation. This powerful methodology allows organizations to model, analyze, and improve their operational processes in a virtual environment before implementing changes in the real world. By leveraging sophisticated software, companies can test hypotheses, identify bottlenecks, and predict outcomes with remarkable accuracy, leading to significant improvements in efficiency, cost reduction, and overall performance.

What is Process Optimization with Simulation?

Process optimization involves identifying and implementing changes to improve the efficiency, effectiveness, and adaptability of a process. When combined with simulation, this transforms into a dynamic and predictive approach. Simulation in this context refers to the use of computer models to mimic the behavior of a real-world system or process over time. Instead of making costly, risky changes in a live environment, businesses can build a digital twin of their operations and experiment within this safe, virtual space.

This allows for a deep dive into complex interactions, dependencies, and variability that might be impossible to discern through traditional analytical methods alone. From production lines and supply chains to customer service queues and hospital patient flows, simulation provides a granular view of how systems perform under different conditions. The ultimate goal of Process Optimization with Simulation is to arrive at the most efficient and effective process design, ensuring resources are utilized optimally and objectives are met consistently.

The Core Benefits of Simulation in Process Improvement

The strategic application of simulation offers a multitude of benefits that extend far beyond simple efficiency gains.

Enhanced Decision Making

Simulation provides data-driven insights that empower decision-makers. By running multiple ‘what-if’ scenarios, stakeholders can visualize the potential impact of various strategies, compare alternatives, and select the optimal path forward with confidence, rather than relying on intuition or limited historical data.

Risk Reduction and Scenario Planning

Introducing changes to complex processes in the real world carries inherent risks, including operational disruptions, financial losses, and reputational damage. Simulation mitigates these risks by allowing organizations to test new processes, technologies, or resource allocations in a virtual sandbox, identifying and rectifying potential issues before they become real-world problems.

Cost Savings and Resource Allocation

By pinpointing inefficiencies, bottlenecks, and redundant steps, simulation directly contributes to cost reduction. It helps in optimizing resource utilization, whether it’s equipment, personnel, or raw materials, ensuring that investments yield maximum returns and unnecessary expenditures are eliminated.

Increased Throughput and Quality

Through the precise analysis afforded by simulation, companies can streamline workflows, reduce idle times, and increase the volume of goods or services produced without compromising quality. This leads to higher productivity and better customer satisfaction.

Key Applications Across Industries

The versatility of process simulation makes it invaluable across a wide spectrum of industries.

Manufacturing and Production

In manufacturing, simulation models are used to design and optimize production lines, assess new equipment layouts, improve material flow, and balance workloads. For instance, in our article on operational efficiency strategies, we delve into how these models can significantly enhance shop floor productivity and reduce lead times.

Logistics and Supply Chain

From warehouse layout optimization to fleet management and supply chain network design, simulation helps logistics companies identify the most efficient routes, storage solutions, and inventory levels to minimize costs and improve delivery times.

Healthcare and Patient Flow

Hospitals and clinics leverage simulation to optimize patient flow, reduce waiting times, improve resource allocation (e.g., operating rooms, beds, staff), and enhance overall patient experience. It can model emergency room processes, clinic scheduling, and even epidemic spread.

Service Operations

Banks, call centers, retail stores, and theme parks use simulation to manage customer queues, optimize staff scheduling, and design service processes that improve customer satisfaction and operational throughput.

How Simulation Drives Operational Excellence

Process simulation is not just a tool for problem-solving; it’s a strategic asset for achieving continuous operational excellence. It fosters a culture of continuous improvement by providing a framework for iterative testing and refinement. The ability to model complex systems, understand interdependencies, and predict future performance empowers organizations to be proactive rather than reactive.

Further insights into advanced simulation methodologies can be found on leading research platforms, such as INFORMS.

Comparative Analysis: Traditional vs. Simulation-Based Optimization

| Feature | Traditional Optimization | Simulation-Based Optimization |

|---|---|---|

| Approach | Trial-and-error, analytical models | Virtual modeling, dynamic testing |

| Risk | High, real-world disruption | Low, virtual environment |

| Cost | Potentially high (rework, downtime) | Lower (software, training) |

| Insight Level | Limited to existing data | Deep, predictive, “what-if” scenarios |

| Speed of Iteration | Slow | Fast |

| Complexity Handling | Difficult for complex systems | Excellent for complex systems |

Implementing Simulation for Success

Successful implementation of process simulation requires careful planning and execution. It typically involves defining the problem, collecting relevant data, building and validating the simulation model, running experiments, analyzing results, and implementing the optimized solutions. Collaboration between process experts, data analysts, and simulation specialists is crucial to ensure the model accurately reflects reality and provides actionable insights.

Conclusion

In an era where efficiency and agility are paramount, Process Optimization with Simulation stands out as a critical methodology for any organization aiming to refine its operations and secure a competitive edge. By providing a safe, cost-effective, and insightful way to test and improve processes, simulation empowers businesses to make smarter decisions, reduce risks, and achieve higher levels of operational excellence. Embracing this technology is not just an option but a strategic imperative for future success.