In today’s fast-paced industrial landscape, achieving peak operational efficiency is no longer an aspiration but a necessity. Businesses are constantly seeking innovative ways to streamline workflows, minimize bottlenecks, and reduce costs. This pursuit invariably leads to the powerful synergy of data analytics and predictive modeling, where Process Optimization with Simulation emerges as a game-changer. By creating virtual models of real-world systems, organizations can test scenarios, anticipate outcomes, and make informed decisions without disrupting actual operations. This article will delve into how simulation is revolutionizing process improvement across various sectors, offering unparalleled insights into complex systems.

- What is Process Optimization with Simulation?

- Why is Simulation Crucial for Optimization?

- Key Steps in Implementing Simulation for Process Optimization

- Real-World Applications and Case Studies

- Challenges and Future Trends in Process Optimization with Simulation

- Conclusion

What is Process Optimization with Simulation?

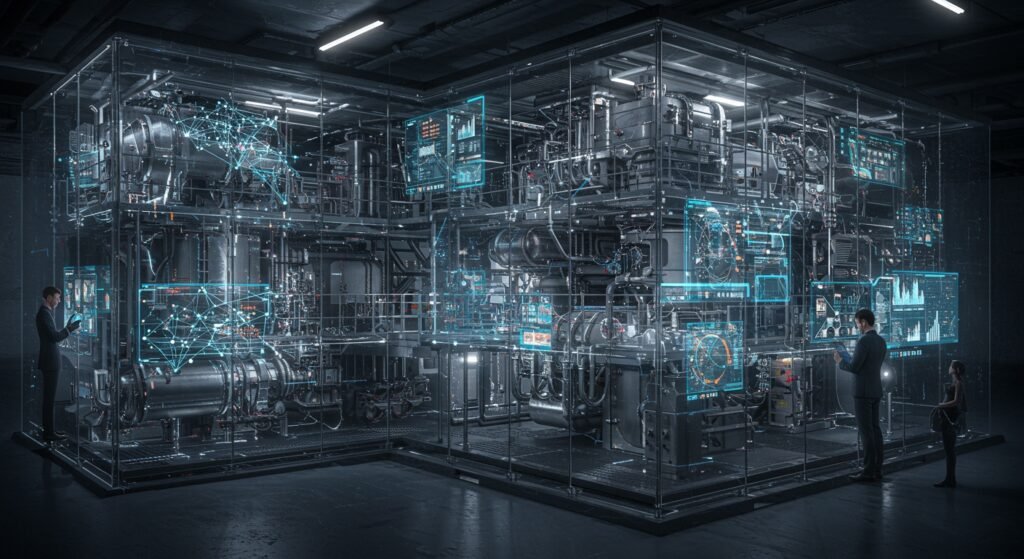

At its core, Process Optimization with Simulation involves building a computer-based model of a real-world system or process. This model acts as a digital twin, allowing users to experiment with different variables, inputs, and constraints in a risk-free virtual environment. Instead of making costly, real-world changes that might disrupt operations, businesses can simulate various scenarios—from supply chain logistics to customer service queues—to identify the most efficient configurations. This methodology enables predictive analysis, helping stakeholders understand the potential impact of decisions before implementation. It’s a fundamental tool in industrial engineering, providing a scientific approach to problem-solving and continuous improvement.

Why is Simulation Crucial for Optimization?

Traditional methods of process improvement often rely on intuition, historical data, or trial-and-error, which can be time-consuming, expensive, and disruptive. Simulation, however, offers a dynamic and comprehensive alternative. It provides a visual representation of the process flow, making complex interactions easier to understand and analyze. This clarity is paramount when dealing with systems that have multiple interconnected parts and variable inputs, such as manufacturing lines or service operations.

Benefits of Simulation

- Risk Reduction: Test new strategies without impacting live operations.

- Cost Savings: Identify inefficiencies and bottlenecks virtually, avoiding expensive physical rework.

- Enhanced Decision-Making: Gain data-driven insights to make optimal choices.

- Improved Throughput: Optimize resource allocation and flow to maximize output.

- Capacity Planning: Accurately forecast future needs and resource requirements.

- Stakeholder Communication: Visual models facilitate better understanding and consensus among teams.

Common Simulation Tools

A variety of software tools are available for process simulation, ranging from general-purpose programming languages to specialized discrete event simulation packages. Some popular examples include Arena, AnyLogic, Simio, and ExtendSim. These tools provide features for building models, running simulations, and analyzing results, often with visual interfaces that simplify the modeling process. Understanding the capabilities of these tools is essential for effective implementation.

Key Steps in Implementing Simulation for Process Optimization

Implementing a successful simulation project involves several critical steps, ensuring that the model accurately reflects reality and provides actionable insights:

- Define the Problem: Clearly articulate the process to be optimized and the specific goals of the simulation (e.g., reduce waiting times, increase production).

- Data Collection: Gather all relevant data, including process times, resource availability, arrival rates, and any associated variability. Accuracy here is crucial.

- Model Development: Construct the simulation model using chosen software, incorporating all defined elements and logic. This phase often involves iterative refinement.

- Verification and Validation: Ensure the model is built correctly (verification) and accurately represents the real system (validation). This might involve comparing simulation outputs to historical data.

- Experimentation: Run multiple simulations under different scenarios (e.g., varying resource levels, different scheduling rules) to test hypotheses.

- Analysis of Results: Interpret the simulation outputs, identifying optimal configurations and potential improvements. Statistical analysis is often employed here.

- Implementation and Monitoring: Apply the recommended changes in the real system and continuously monitor their impact, ready for further iterative improvements.

For more insights on data collection strategies, consider reading our article on Data-Driven Decision Making in Business.

Real-World Applications and Case Studies

The versatility of simulation makes it applicable across diverse sectors. Here’s how it’s making a difference:

Manufacturing Efficiency

In manufacturing, simulation is used to optimize production lines, balance workloads, and manage inventory. Companies can simulate changes in machine capacity, staffing levels, or layout to predict their impact on throughput and lead times. This enables precise bottleneck identification and efficient resource allocation. For example, a car manufacturer might simulate a new assembly line configuration to predict its effect on production volume before investing in physical changes.

Healthcare Workflow

Hospitals and clinics leverage simulation to improve patient flow, reduce waiting times, and optimize resource utilization. Simulating emergency room operations, for instance, can help administrators determine optimal staffing levels for doctors, nurses, and beds to minimize patient queues and improve care delivery. This also extends to scheduling appointments and managing equipment usage.

Here’s a comparison of traditional vs. simulation-based optimization:

| Feature | Traditional Optimization | Simulation-Based Optimization |

|---|---|---|

| Risk of Disruption | High (trial-and-error in real system) | Low (virtual environment) |

| Cost of Experimentation | High (physical changes, downtime) | Low (software, computation) |

| Complexity Handling | Limited (simple systems) | High (complex, dynamic systems) |

| Predictive Power | Retrospective analysis | Prospective analysis, “what-if” scenarios |

| Speed of Analysis | Slow (real-world testing cycles) | Fast (accelerated time) |

For further reading on the broader field of industrial engineering, you might find valuable resources on sites like the Institute of Industrial and Systems Engineers.

Challenges and Future Trends in Process Optimization with Simulation

While powerful, implementing simulation for process optimization isn’t without its challenges. Data availability and quality can be significant hurdles, as accurate models rely heavily on precise input data. Model complexity and validation also require expertise. Furthermore, integrating simulation results into daily operational decisions demands strong change management and stakeholder buy-in.

Looking ahead, several exciting trends are shaping the future of simulation. The integration of Artificial Intelligence (AI) and Machine Learning (ML) with simulation is becoming increasingly prevalent, enabling more intelligent scenario generation and automated optimization. Cloud-based simulation platforms are making powerful tools more accessible, reducing the need for expensive on-premise infrastructure. The rise of digital twins, which are highly accurate virtual replicas of physical assets and processes, will further bridge the gap between simulation and real-time operations, allowing for dynamic, continuous optimization. These trends promise to make process optimization even more sophisticated and indispensable for businesses navigating increasingly complex environments.

Conclusion

Process Optimization with Simulation is no longer a niche academic tool; it’s a mainstream, indispensable strategy for businesses aiming for operational excellence. By offering a risk-free environment to experiment and predict outcomes, it empowers organizations to make data-driven decisions that lead to significant improvements in efficiency, cost reduction, and overall performance. As technology continues to advance, the capabilities of simulation will only grow, solidifying its role as a cornerstone of modern industrial engineering and business process management.