The manufacturing landscape is undergoing a profound transformation, ushering in an era defined by efficiency, connectivity, and intelligence. At the heart of this revolution lies the concept of Smart Factories and IoT Integration. These advanced production facilities leverage cutting-edge technologies, primarily the Internet of Things (IoT), to create highly automated, self-optimizing systems that can respond in real-time to changing demands and conditions. This integration isn’t just about automation; it’s about creating an interconnected ecosystem where machines, systems, and people communicate seamlessly, leading to unprecedented levels of productivity and innovation.

As industries worldwide strive for greater resilience and competitiveness, the adoption of smart factory principles becomes not just an advantage, but a necessity. This article delves into what constitutes a smart factory, the pivotal role of IoT, the myriad benefits they offer, and what the future holds for this transformative trend in industrial engineering.

What are Smart Factories and IoT Integration?

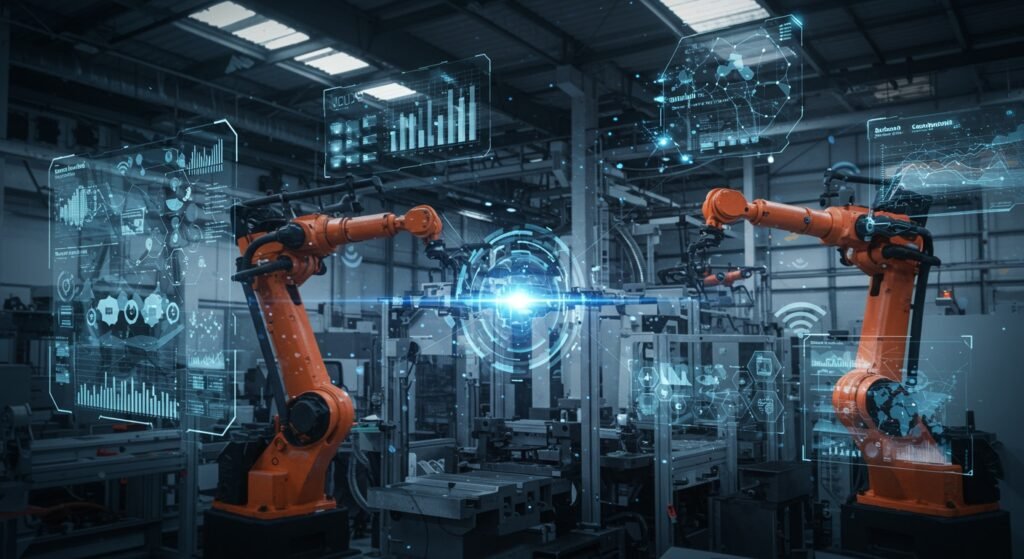

A smart factory is a highly digitized and connected production facility that uses intelligent, networked systems to create a fully integrated and collaborative manufacturing environment. It’s a foundational component of Industry 4.0, the fourth industrial revolution. At its core, it relies on the Internet of Things (IoT), where physical objects—machines, sensors, robots, and products—are embedded with sensors, software, and other technologies to connect and exchange data with other devices and systems over the internet.

Smart Factories and IoT Integration means that every piece of equipment, from conveyor belts to robotic arms, is capable of generating and exchanging data. This real-time data flow provides unprecedented visibility into production processes, enabling predictive maintenance, dynamic scheduling, and adaptive quality control. It moves beyond simple automation to create intelligent systems that can learn, adapt, and make autonomous decisions, optimizing operations without constant human intervention.

Key Technologies Driving Smart Factories

Several advanced technologies converge to power smart factories:

- Industrial Internet of Things (IIoT): The bedrock, connecting devices, sensors, and machines to collect vast amounts of operational data.

- Artificial Intelligence (AI) and Machine Learning (ML): Used to analyze IIoT data, identify patterns, predict outcomes (like equipment failure), and optimize processes.

- Big Data Analytics: Processing the enormous volumes of data generated by connected systems to derive actionable insights.

- Cloud Computing: Provides scalable infrastructure for storing and processing IIoT data, and hosting AI/ML applications.

- Robotics and Automation: Advanced robots, including collaborative robots (cobots), handle repetitive or dangerous tasks, improving safety and precision.

- Cyber-Physical Systems (CPS): Integrates computational and physical components, allowing for real-time control and monitoring of physical processes.

- Digital Twins: Virtual replicas of physical assets, processes, or systems that can be used for simulations, performance monitoring, and predictive analysis.

Unlocking the Benefits of Smart Factories and IoT Integration

The adoption of smart factory concepts, particularly with robust Smart Factories and IoT Integration, yields a multitude of advantages that redefine operational excellence and competitive positioning. These benefits extend across the entire value chain, from raw material handling to final product delivery.

Increased Efficiency and Productivity

By automating processes and optimizing workflows based on real-time data, smart factories significantly reduce idle time, minimize human error, and accelerate production cycles. Machines can work continuously, and production lines can be dynamically adjusted to meet demand fluctuations, leading to higher throughput with fewer resources.

Enhanced Quality Control

IoT sensors can monitor product quality at every stage of production, detecting defects instantaneously. This proactive approach allows for immediate corrections, preventing large batches of faulty products and ensuring consistent, high-quality output. The data gathered provides insights for continuous improvement of manufacturing processes.

Predictive Maintenance

Instead of reactive repairs, IoT-enabled sensors monitor machine health in real-time, predicting potential failures before they occur. This allows for scheduled maintenance, reducing downtime, extending equipment lifespan, and preventing costly breakdowns. For more details on this, you can check out this industrial science technology article.

Cost Reduction

Optimized energy consumption, reduced waste, improved asset utilization, and minimized downtime all contribute to significant cost savings. The data-driven insights help identify inefficiencies and areas for improvement that were previously hidden.

Improved Worker Safety

Automation handles dangerous or repetitive tasks, reducing the risk of accidents and injuries. IoT sensors can also monitor environmental conditions and worker presence, adding layers of safety protocols. For information on smart safety systems, see our AI in Manufacturing post.

| Benefit Area | Impact of Smart Factories and IoT Integration |

|---|---|

| Efficiency | Reduced downtime, faster production cycles, optimized resource use. |

| Quality | Real-time defect detection, consistent product standards. |

| Maintenance | Shift from reactive to proactive (predictive) repairs. |

| Cost | Lower operational expenses, reduced waste and energy consumption. |

| Safety | Fewer human-related accidents, better environmental monitoring. |

Navigating Challenges and Finding Solutions

While the benefits are compelling, implementing Smart Factories and IoT Integration comes with its own set of challenges. Cybersecurity is a paramount concern, as interconnected systems present new vulnerabilities for data breaches and operational disruptions. The sheer volume of data generated requires robust infrastructure and sophisticated analytics capabilities. Furthermore, the integration of legacy systems with new technologies can be complex and costly.

To overcome these, organizations must prioritize robust cybersecurity measures, invest in scalable cloud solutions, and adopt modular, open architectures that facilitate integration. Workforce upskilling is also crucial, as employees need new competencies to manage and interpret data-driven operations. Strategic planning and a phased approach are key to successful implementation.

The Future Landscape of Manufacturing

The trajectory of smart factories points towards even greater autonomy and intelligence. We can expect more widespread adoption of AI-driven optimization, self-organizing production lines, and increased human-robot collaboration. The concept of “lights-out” manufacturing, where facilities operate with minimal human presence, will become more common for certain processes.

Ultimately, Smart Factories and IoT Integration are not just about upgrading technology; they are about fundamentally rethinking how products are designed, made, and delivered. They promise a future of manufacturing that is more agile, sustainable, and responsive to the ever-evolving demands of the global market, truly marking a significant trend in industrial engineering.