Smart Manufacturing: Integrating AI and Robotics for Operational Excellence

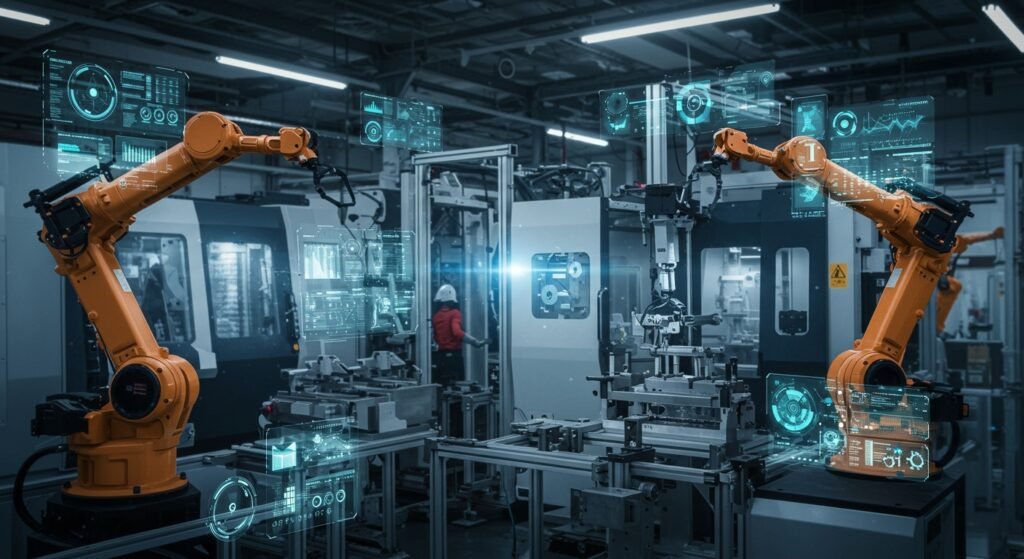

In the rapidly evolving industrial landscape, smart manufacturing stands as the pinnacle of innovation, promising a revolution in how goods are produced. This paradigm shift leverages cutting-edge technologies like Artificial Intelligence (AI) and robotics to create highly efficient, adaptive, and sustainable production systems. By integrating these powerful tools, businesses can unlock unprecedented levels of operational excellence, transforming traditional factories into intelligent, interconnected ecosystems. This article explores the core components of smart manufacturing, its benefits, applications, and the challenges manufacturers must navigate to thrive in this new era.

Table of Contents

- What is Smart Manufacturing?

- Key Benefits of Integrating AI and Robotics

- Real-World Applications and Use Cases

- The Challenges and How to Overcome Them

- The Future of Manufacturing is Smart

What is Smart Manufacturing?

Smart manufacturing represents a technologically advanced approach to production that employs computer-integrated manufacturing, high levels of adaptability, and rapid design changes. It is a broad category of manufacturing that involves a constant connection to information via the internet of things (IoT) and big data. At its heart, it’s about making factories smarter, more responsive, and more productive. It moves beyond simple automation to create a holistic, interconnected system where machines, processes, and people communicate seamlessly.

Beyond Automation: The Role of AI

AI is the brain of smart manufacturing. It enables machines to learn, reason, and make decisions autonomously. From predictive analytics that foresee equipment failures to machine learning algorithms that optimize production schedules and quality control, AI transforms raw data into actionable insights. This intelligence allows systems to adapt to changing conditions, optimize resource allocation, and continuously improve performance without constant human intervention.

Robotics: The Physical Backbone

While AI provides the intelligence, robotics offers the physical capability. Modern industrial robots are no longer just rigid, repetitive machines. Collaborative robots (cobots), mobile robots, and advanced manipulators are now capable of complex tasks, working safely alongside humans, and handling diverse product variations. They execute tasks with precision, speed, and endurance, performing everything from intricate assembly to heavy material handling, significantly boosting throughput and safety on the factory floor.

Key Benefits of Integrating AI and Robotics

The synergy between AI and robotics delivers a multitude of advantages for manufacturers looking to achieve operational excellence. These benefits extend across the entire production lifecycle, from design to delivery.

Enhanced Efficiency and Productivity

AI-driven optimization ensures machines operate at peak performance, minimizing idle time and maximizing output. Robotics handle repetitive or dangerous tasks faster and more consistently than humans, leading to significant increases in production speed and volume. This translates directly to higher productivity and better utilization of resources.

Improved Quality and Reduced Waste

AI-powered vision systems can detect defects with far greater accuracy and speed than manual inspection. This proactive quality control reduces errors, minimizes rework, and significantly cuts down on material waste. The precision of robots also ensures consistent product quality, reducing variability across batches.

Predictive Maintenance and Downtime Reduction

One of the most impactful benefits is the ability to predict machine failures before they occur. AI analyzes data from sensors on equipment, identifying patterns that indicate potential issues. This allows for scheduled maintenance, avoiding costly unexpected breakdowns and drastically reducing downtime. This proactive approach ensures continuous operation and extends the lifespan of machinery.

Greater Flexibility and Customization

Smart manufacturing systems are inherently more agile. AI can quickly reconfigure production lines for new products or design changes, while reprogrammable robots can adapt to different tasks or product variations. This flexibility is crucial for meeting consumer demands for customized products and rapidly responding to market shifts. For more insights on adaptability, you can read our blog post on Agile Manufacturing Strategies.

Real-World Applications and Use Cases

The integration of AI and robotics is transforming various aspects of manufacturing across diverse industries.

Automated Assembly Lines

Robots equipped with AI vision are revolutionizing assembly. They can pick and place components, perform welding, painting, and fastening with incredible precision, often working collaboratively with human operators on complex products. This is especially prevalent in automotive and electronics manufacturing.

Quality Inspection with Computer Vision

AI-powered computer vision systems can inspect products for defects, verify assembly, and ensure compliance with quality standards at high speeds. These systems can identify microscopic flaws that human eyes might miss, ensuring only perfect products reach the market. This technology is critical in industries requiring stringent quality control, such as medical devices and aerospace.

Supply Chain Optimization

AI algorithms analyze vast datasets from supply chains to predict demand fluctuations, optimize inventory levels, and streamline logistics. Robotics in warehouses, such as autonomous mobile robots (AMRs), manage storage and retrieval, ensuring materials are where they need to be, precisely when they’re needed. This holistic approach enhances resilience and reduces costs across the entire supply chain.

The Challenges and How to Overcome Them

While the promise of smart manufacturing is immense, adopting these technologies comes with its own set of hurdles.

| Challenge | Solution/Strategy |

|---|---|

| High Initial Investment | Phased implementation, focus on ROI, explore government incentives. |

| Data Security & Privacy | Robust cybersecurity protocols, secure network infrastructure, data encryption. |

| Workforce Skill Gaps | Reskilling and upskilling programs, collaboration with educational institutions. |

| Integration Complexity | Modular systems, open standards, expert consultation, pilot projects. |

Data Security and Privacy

As factories become more connected, the risk of cyber threats increases. Protecting sensitive production data and intellectual property is paramount. Manufacturers must invest in robust cybersecurity measures, including secure network architectures, encryption, and regular security audits. For further reading on industrial cybersecurity, explore resources like ISA’s Cybersecurity for Industrial Control Systems.

Workforce Adaptation and Skill Gaps

The shift to smart manufacturing requires new skills from the workforce. Tasks will evolve from manual labor to monitoring, programming, and maintaining complex systems. Companies must invest in training and upskilling programs to prepare their employees for these new roles, fostering a culture of continuous learning.

Initial Investment and Integration Complexity

Implementing AI and robotics can involve significant upfront costs and complex integration processes. A phased approach, starting with pilot projects, can help manage investment and demonstrate ROI. Choosing modular, scalable solutions that can integrate with existing infrastructure is also key to a smoother transition.

The Future of Manufacturing is Smart

The trajectory towards fully integrated, intelligent factories is undeniable. As AI capabilities advance and robotics become more versatile and affordable, their widespread adoption in manufacturing will only accelerate. This evolution will not only redefine production processes but also empower businesses to be more competitive, innovative, and resilient in the global market. Embracing smart manufacturing today is not just an option; it’s a strategic imperative for long-term success.

By leveraging the power of AI and robotics, manufacturers can move beyond traditional limitations, achieving a level of operational excellence previously thought impossible. The factories of tomorrow will be smart, agile, and ready for whatever the future holds.