The Rise of Industry 5.0: Shaping a Human-Centric Industrial Future

The industrial landscape is constantly evolving, with each new ‘revolution’ bringing profound changes to how we produce, work, and live. Following Industry 4.0’s focus on automation and data exchange, we now stand on the cusp of a new era: The Rise of Industry 5.0. This isn’t just about more technology; it’s a paradigm shift that places the well-being of the worker and the sustainability of our planet at its core, creating a more resilient and human-centric industrial future. This article delves into the defining characteristics, key drivers, and transformative potential of this exciting new phase.

Table of Contents

- Introduction: Beyond Automation

- Defining Industry 5.0: The Human-Centric Revolution

- Key Pillars of Industry 5.0: Resilience, Sustainability, and Human-Centricity

- Technologies Driving The Rise of Industry 5.0

- Impacts and Benefits: Why Industry 5.0 Matters

- Challenges and Considerations

- The Future Landscape

- Conclusion: A Synergistic Tomorrow

Introduction: Beyond Automation

For decades, industrial progress has often been equated with increased automation and efficiency. From the steam engine (Industry 1.0) to mass production (2.0) and digital computing (3.0), each phase built upon the last. Industry 4.0 ushered in the era of smart factories, IoT, and AI, connecting machines and optimizing processes. However, a crucial element was sometimes overlooked: the human. The Rise of Industry 5.0 directly addresses this, seeking to balance technological advancement with human value, societal benefits, and environmental responsibility. It’s about combining the precision and speed of machines with the creativity and critical thinking of people.

Defining Industry 5.0: The Human-Centric Revolution

Industry 5.0 is not a replacement for Industry 4.0 but rather an evolution. It focuses on how humans and machines can work synergistically, leveraging the strengths of both. The European Commission defines Industry 5.0 as an approach that “recognizes the power of industry to achieve societal goals beyond employment and growth to become a provider of prosperity, by making production respectful of the planetary boundaries and by placing the well-being of the industry worker at the centre of the production process.” This shift is critical as industries face increasing demands for customization, sustainability, and resilience against global disruptions.

Key Pillars of Industry 5.0: Resilience, Sustainability, and Human-Centricity

At its core, Industry 5.0 is built upon three fundamental pillars that guide its implementation and objectives:

Resilience in Supply Chains

The COVID-19 pandemic and other geopolitical events highlighted the fragility of global supply chains. Industry 5.0 emphasizes building more robust and agile production systems that can withstand unexpected shocks. This includes localizing production, diversifying suppliers, and implementing advanced data analytics to predict and mitigate disruptions. The goal is to ensure continuous operation even in the face of adversity.

Sustainable Production Practices

Environmental concerns are paramount in Industry 5.0. This pillar focuses on reducing waste, optimizing resource consumption, and transitioning to circular economy principles. It involves adopting greener manufacturing processes, using renewable energy, and designing products for longevity and recyclability. The aim is to create an industrial ecosystem that minimizes its ecological footprint. For more insights into sustainable practices, you might find valuable information on the European Commission’s Industry 5.0 page.

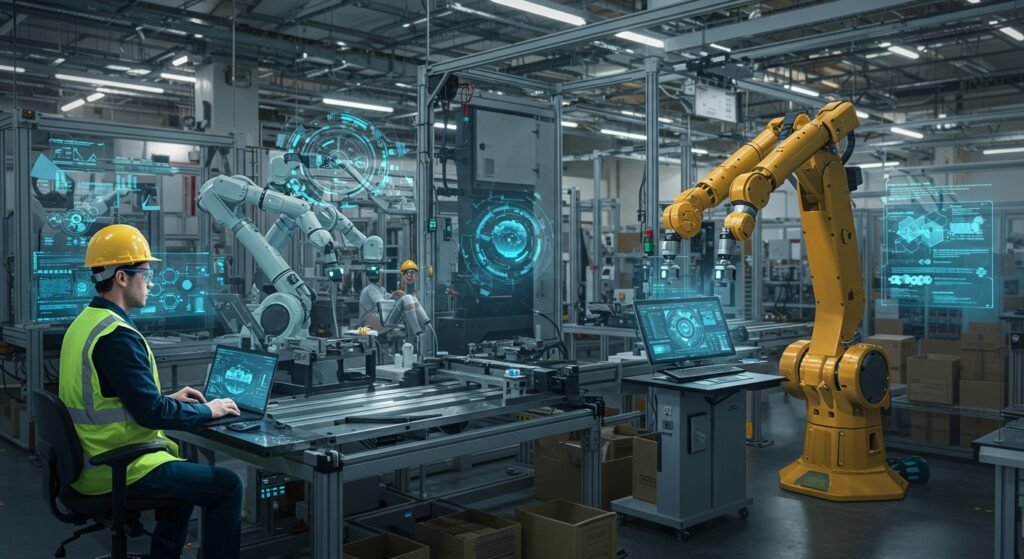

Human-Centric Collaboration: The Role of Cobots

Perhaps the most distinctive feature of Industry 5.0 is its emphasis on the human element. Instead of replacing human workers, technology, particularly collaborative robots (cobots), is designed to augment human capabilities. Cobots work alongside humans, assisting with repetitive, heavy, or dangerous tasks, thereby improving safety, productivity, and job satisfaction. This collaboration liberates human workers to focus on creative problem-solving, innovation, and tasks requiring fine motor skills or complex decision-making.

Technologies Driving The Rise of Industry 5.0

While the philosophy is human-centric, advanced technologies are crucial enablers. Key technologies include:

- Collaborative Robotics (Cobots): Designed for safe interaction with humans.

- Artificial Intelligence (AI) and Machine Learning (ML): For data analysis, predictive maintenance, and optimizing human-machine interfaces.

- Internet of Things (IoT): Connecting devices and collecting real-time data for better insights.

- Digital Twins: Virtual models of physical objects or processes, enabling simulations and optimizations.

- Advanced Human-Machine Interfaces (HMI): Intuitive interfaces like augmented reality (AR) and virtual reality (VR) to enhance worker interaction.

- Big Data Analytics: Processing vast amounts of data to inform decision-making in real-time.

Impacts and Benefits: Why Industry 5.0 Matters

The widespread adoption of Industry 5.0 principles promises numerous benefits:

| Benefit Category | Description | Example |

|---|---|---|

| Enhanced Productivity | Optimized human-machine collaboration leads to higher output. | Cobots handle heavy lifting, allowing human workers to focus on quality control. |

| Improved Worker Well-being | Reduced repetitive strain injuries and safer working environments. | Ergonomic workspaces designed with human comfort and safety in mind. |

| Greater Customization | Agile production systems allow for mass customization of products. | Consumers can order bespoke products manufactured on demand. |

| Environmental Stewardship | Lower energy consumption and reduced waste through circular economy principles. | Factories powered by renewable energy, minimizing carbon footprint. |

| Economic Resilience | Stronger local supply chains and adaptability to global disruptions. | Production can quickly pivot to new products or adjust to supply shortages. |

Challenges and Considerations

While the vision of Industry 5.0 is compelling, its implementation comes with challenges. These include the significant initial investment in new technologies, the need for reskilling the workforce, ensuring data security and privacy, and developing new ethical guidelines for human-machine interaction. Overcoming these hurdles will require concerted efforts from governments, industries, and educational institutions.

The Future Landscape

Looking ahead, the influence of Industry 5.0 will extend beyond the factory floor. It will shape educational curricula, redefine job roles, and foster a more sustainable global economy. The transition will require continuous innovation and collaboration across various sectors. For a deeper dive into how this might impact individual careers, consider exploring resources on industrial career paths.

Conclusion: A Synergistic Tomorrow

The Rise of Industry 5.0 represents a significant step forward, moving beyond mere technological advancement to embrace a more holistic and responsible approach to industrial production. By prioritizing human well-being, environmental sustainability, and economic resilience, Industry 5.0 aims to create a future where technology serves humanity, not the other way around. It’s a vision of industry that is not only smart and efficient but also ethical, sustainable, and truly human-centric, ensuring a prosperous future for all.