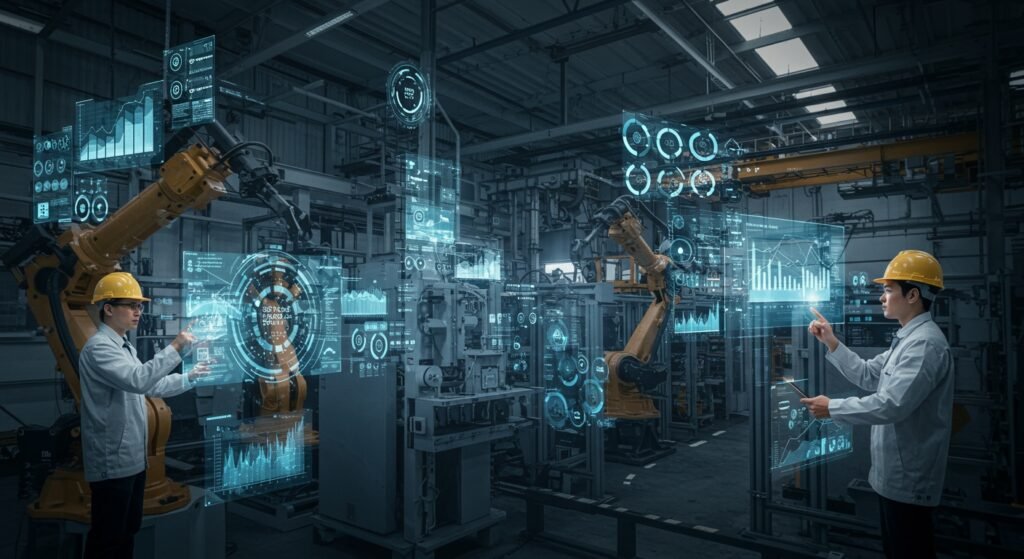

In an era increasingly defined by data, the synergy between data science and traditional engineering disciplines has never been more critical. Industrial Engineering (IE), a field focused on optimizing complex processes, systems, and organizations, is undergoing a profound transformation. This evolution is largely driven by The Role of Data Science in IE, which provides unprecedented capabilities for analysis, prediction, and optimization. By leveraging advanced analytical techniques, machine learning, and statistical modeling, industrial engineers can now tackle challenges with greater precision, efficiency, and foresight than ever before.

This article delves into how data science is reshaping industrial engineering, exploring its key applications, the challenges it presents, and its promising future. From enhancing manufacturing processes to streamlining supply chains, the integration of data science offers a powerful toolkit for creating more robust, responsive, and intelligent industrial systems.

Table of Contents

- Understanding the Synergy Between Data Science and Industrial Engineering

- Key Applications of Data Science in IE

- Challenges and Considerations

- Future Outlook: The Evolving Role of Data Science in IE

- Conclusion

Understanding the Synergy Between Data Science and Industrial Engineering

Industrial Engineering traditionally relies on mathematical modeling, statistical methods, and operational research to improve performance. Data science, with its emphasis on extracting insights from large and complex datasets, naturally complements these existing methodologies. It empowers industrial engineers to move beyond reactive problem-solving to proactive, data-driven decision-making. This convergence allows for the identification of hidden patterns, prediction of future outcomes, and the creation of highly optimized systems that can adapt to changing conditions. The integration enables a more holistic view of operations, bridging the gap between theoretical models and real-world performance data.

Key Applications of Data Science in IE

The Pivotal Role of Data Science in IE: Predictive Maintenance

One of the most impactful applications of data science in industrial settings is predictive maintenance. By analyzing data from sensors on machinery (e.g., temperature, vibration, pressure), data science algorithms can predict equipment failures before they occur. This allows for scheduled maintenance, reducing downtime, extending asset lifespan, and significantly cutting operational costs. Rather than following fixed maintenance schedules or reacting to breakdowns, IE professionals can use data insights to maintain equipment precisely when needed, optimizing resource allocation and preventing costly disruptions. To learn more about the specifics of this revolutionary approach, you can explore further details on predictive maintenance.

Supply Chain Optimization through Data Analytics

Data science provides powerful tools for optimizing complex supply chains. Demand forecasting, inventory management, logistics, and transportation all benefit from advanced analytics. Machine learning models can predict customer demand with greater accuracy, leading to optimized inventory levels, reduced waste, and improved order fulfillment rates. Route optimization algorithms, powered by real-time traffic and weather data, can ensure goods are delivered efficiently. This leads to substantial savings in fuel costs and delivery times, enhancing overall supply chain resilience and responsiveness.

Quality Control and Anomaly Detection

Ensuring product quality is paramount in industrial engineering. Data science techniques, such as statistical process control (SPC) combined with machine learning, enable real-time monitoring of production lines. Anomalies or deviations from quality standards can be detected instantly, allowing for immediate corrective action. This proactive approach minimizes defects, reduces scrap rates, and ensures consistent product quality, which is crucial for maintaining brand reputation and customer satisfaction. Computer vision, a sub-field of data science, can also be employed for automated visual inspection, significantly speeding up the quality control process.

Process Improvement and Efficiency

Data-driven insights are invaluable for continuous process improvement. Industrial engineers can use data science to analyze process bottlenecks, identify inefficiencies, and simulate different scenarios to determine optimal configurations. Techniques like A/B testing, process mining, and simulation modeling help in understanding complex interactions within a system and validating improvements before costly implementation. This leads to more efficient workflows, reduced cycle times, and enhanced resource utilization across the organization. This focus on efficiency and data-driven decision-making will continue to evolve, especially as we explore future trends in the field.

Comparative Analysis of Data Science Techniques in IE

| Technique | Primary Application in IE | Benefits |

|---|---|---|

| Predictive Modeling | Demand Forecasting, Predictive Maintenance | Reduces costs, optimizes inventory, prevents failures |

| Optimization Algorithms | Supply Chain Logistics, Production Scheduling | Minimizes lead times, maximizes throughput |

| Machine Learning (e.g., Anomaly Detection) | Quality Control, Cybersecurity | Early detection of defects/threats, improved reliability |

| Statistical Process Control | Manufacturing Quality, Process Monitoring | Ensures consistent product quality, identifies deviations |

Challenges and Considerations

Despite its immense potential, integrating data science into industrial engineering comes with its own set of challenges. Data quality is often a major hurdle; incomplete, inconsistent, or noisy data can lead to flawed insights. There’s also a significant demand for professionals with a hybrid skill set – individuals who possess both deep IE knowledge and strong data science expertise. Integrating new data infrastructure and tools with legacy systems can be complex and costly. Furthermore, ethical considerations regarding data privacy and algorithmic bias must be carefully managed to ensure fair and responsible deployment of data science solutions.

Future Outlook: The Evolving Role of Data Science in IE

The future of industrial engineering is inextricably linked with advancements in data science and artificial intelligence. We can expect to see even more sophisticated applications, including the widespread adoption of digital twins for real-time monitoring and simulation of entire operational systems. AI-driven automation, personalized manufacturing, and hyper-optimized smart factories will become increasingly common. As data generation continues to explode with the Internet of Things (IoT), the ability of industrial engineers to harness and interpret this data will be a defining factor in competitive advantage. The continuous evolution of data science tools and techniques will ensure that The Role of Data Science in IE remains central to innovation and operational excellence.

Conclusion

The Role of Data Science in IE is no longer a nascent concept but a fundamental pillar driving modern industrial systems. From enhancing predictive maintenance and optimizing supply chains to ensuring stringent quality control and fostering continuous process improvement, data science offers an unparalleled opportunity for industrial engineers to unlock new levels of efficiency, productivity, and innovation. Embracing these data-driven methodologies is essential for organizations looking to thrive in an increasingly complex and competitive global landscape. The future of industrial engineering is undeniably data-rich, intelligent, and optimized.