Introduction to Cold Chain Logistics

Cold chain logistics refers to the specialized temperature-controlled supply chain that is essential for the transportation and storage of perishable goods. This meticulous process ensures that products such as pharmaceuticals, food and beverages, and biotechnology materials maintain their integrity and quality throughout the distribution cycle. The cold chain logistics framework is crucial in preventing spoilage and degradation, enabling businesses to deliver products to consumers in optimal condition.

The process begins at the point of origin, where perishable items are initially stored under specific temperature conditions. As products move through various stages – including processing, packaging, transportation, and distribution – the cold chain must remain intact. This is achieved through advanced technologies and methods such as refrigerated trucks, temperature-controlled warehouses, and monitoring systems equipped with real-time tracking capabilities. Such measures help minimize the risk of damage caused by temperature fluctuations, thereby protecting both the efficacy of pharmaceuticals and the freshness of food items.

In various industries, particularly the pharmaceutical sector, cold chain logistics is of paramount importance. Vaccines and other temperature-sensitive medications require precise handling and storage temperatures to preserve their efficacy. Similarly, the food and beverage industry relies heavily on cold chain logistics to ensure that perishable items like dairy products, meat, fruits, and vegetables are delivered without compromise in quality. Additionally, the biotechnology sector has witnessed a growing demand for efficient cold chain solutions to safeguard sensitive biological materials, thus underscoring the importance of this logistics model.

As the demand for perishable goods increases alongside global commerce, understanding and implementing effective cold chain logistics practices is vital for businesses aiming to ensure product safety and compliance with regulatory standards, ultimately leading to improved consumer trust and satisfaction.

The Components of Cold Chain Logistics

Cold chain logistics is vital for preserving the quality and safety of temperature-sensitive products, especially in industries such as food, pharmaceuticals, and biotechnology. Several interlinked components are essential for an effective cold chain system, ensuring that products remain within specified temperature ranges throughout the supply chain.

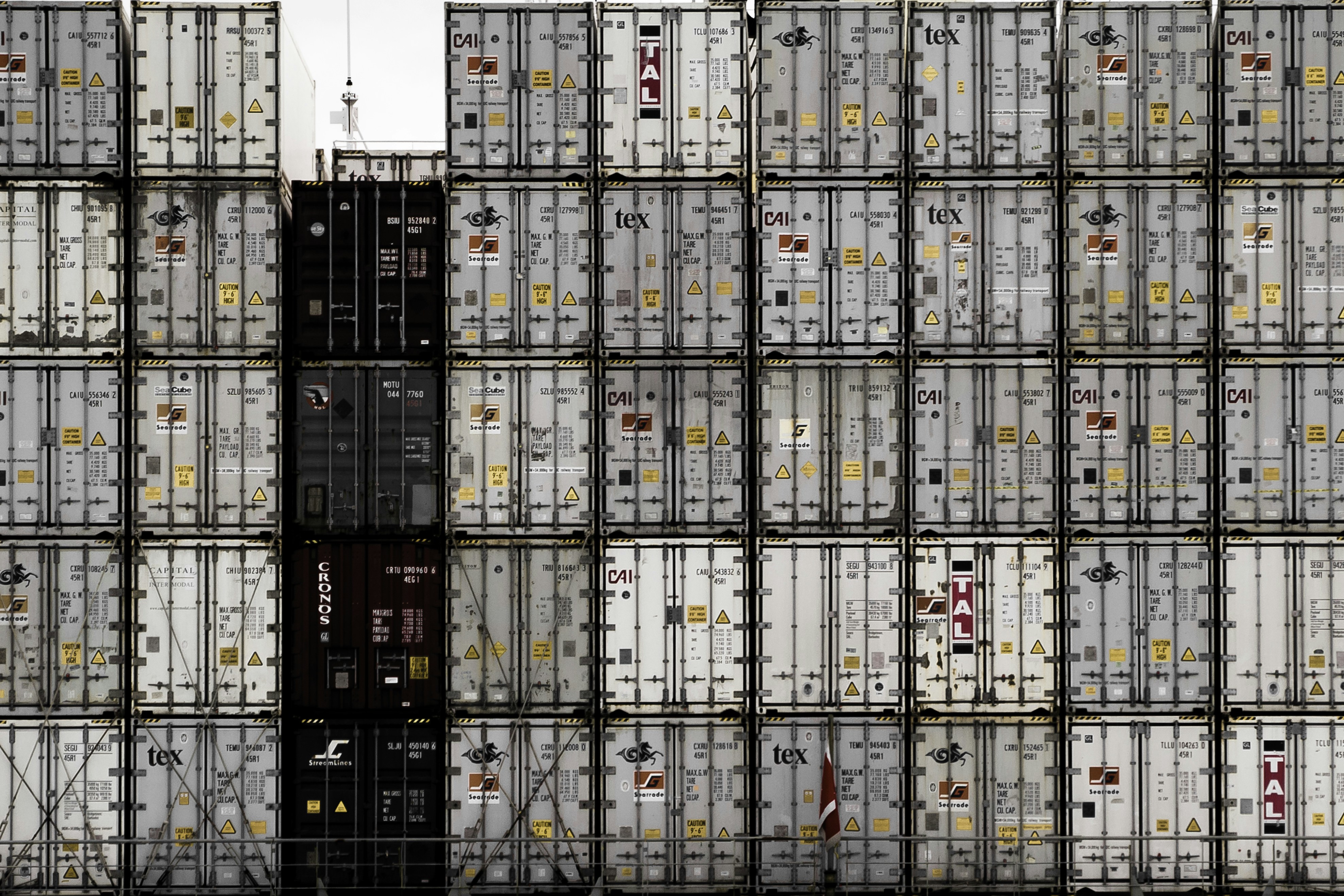

The first component is refrigerated transport, which encompasses vehicles equipped with temperature control systems. These vehicles, whether trucks, containers, or airplanes, are crucial for maintaining the cold chain during transit. They are designed to manage internal temperatures effectively, thus preventing spoilage and degradation of perishable goods.

Next, we have temperature-controlled storage facilities, which serve as critical nodes within the cold chain. These warehouses are designed to provide a consistent chill or freeze environment, safeguarding sensitive items until they are ready for distribution. Advanced insulation and precise climate control technologies play a key role in optimizing storage efficacy, reducing energy consumption while ensuring product integrity.

Another vital element of cold chain logistics is monitoring systems. These systems utilize a combination of temperature sensors and data logging equipment to track temperature fluctuations in real-time. By continuously monitoring conditions throughout the cold chain, businesses can quickly identify any deviations and take necessary action to prevent product loss. Data analytics further enhance the effectiveness of these systems, allowing for predictive maintenance and proactive decision-making.

Finally, effective packaging solutions are indispensable in preserving the cold chain. Insulated containers, gel packs, and phase change materials can help maintain temperatures during transport and storage. These innovative packaging strategies not only offer protection from external temperature shifts but also contribute to reducing the risk of thermal shock, ultimately ensuring temperature-sensitive products are delivered in optimal condition.

Why Cold Chain Logistics is Essential

Cold chain logistics serve as a crucial component in the transportation and storage of temperature-sensitive products, with particular emphasis on food items and pharmaceuticals. The necessity of maintaining an uninterrupted cold chain cannot be overstated; it plays a pivotal role in ensuring product safety. When perishable goods or sensitive pharmaceuticals are subjected to temperature fluctuations, their safety and quality can be compromised, posing serious health risks to consumers. The importance of adhering to temperature control protocols is well-demonstrated in sectors such as food distribution, where improper handling has led to numerous cases of foodborne illness.

Furthermore, cold chain logistics are instrumental in reducing spoilage and waste. In the case of fresh produce, seafood, and meat products, failing to maintain the correct temperature during transit and storage directly contributes to a higher rate of spoilage. According to industry reports, it is estimated that a significant portion of perishable goods is wasted each year due to inadequate cold chain management, leading to financial losses for producers and increased prices for consumers. Implementing robust cold chain logistics reduces these losses, enhances operational efficiency, and supports sustainable practices.

Another critical reason for the emphasis on cold chain logistics is the maintenance of product efficacy, particularly in the pharmaceutical sector. Many vaccines and medications require stringent temperature controls to remain effective. The impact of neglecting cold chain practices can be catastrophic, as seen during instances when vaccines were rendered ineffective due to improper temperature management. Regulatory compliance is also a vital aspect; various governments impose strict guidelines regarding the storage and transportation of temperature-sensitive products, and failing to adhere to such regulations can lead to substantial legal repercussions.

In conclusion, the significance of cold chain logistics is paramount in assuring the safety, efficacy, and quality of temperature-sensitive products. From reducing waste to complying with regulatory standards, effective cold chain practices are essential for industries reliant on perishable goods and pharmaceuticals.

Challenges in Cold Chain Logistics

Cold chain logistics is crucial for maintaining the integrity of temperature-sensitive products, yet it faces several challenges that can disrupt operations and pose risks to the supply chain. One of the most significant issues is equipment failure. Refrigeration units, monitoring devices, and transportation vehicles are subject to wear and tear, which can lead to temperature deviations that compromise product quality. Frequent maintenance and investment in reliable technology are essential to mitigate these risks.

Temperature fluctuations can also arise from various factors, including inadequate insulation, inefficient loading practices, or external environmental conditions. Any breach in temperature control can lead to spoilage or reduction in product efficacy, particularly in the pharmaceutical or food industries. Hence, continuous temperature monitoring and alerts are necessary to ensure compliance with stringent regulations and to protect public health.

Regulatory compliance presents another layer of complexity in cold chain logistics. Companies must navigate various standards and guidelines established by governmental bodies, which can vary by region and product type. Ensuring adherence to these regulations requires comprehensive training for staff and meticulous tracking of compliance documentation, adding to the operational burden.

Additionally, labor shortages have emerged as a critical challenge in the logistics sector, impacting the efficiency of operations. Skilled labor is essential for managing sophisticated cold chain systems, yet many companies face difficulties in hiring and retaining qualified workers. This shortage can lead to delays in service delivery and increased operational costs as firms struggle to maintain consistent quality amidst the workforce challenges.

Collectively, these challenges underscore the need for innovative solutions and effective strategies in cold chain logistics, ultimately ensuring that the integrity of temperature-sensitive products is upheld throughout the supply chain.

Innovations in Cold Chain Technology

The evolution of cold chain logistics has been significantly influenced by technological advancements that enhance operational efficiency and accountability. Notable among these innovations are the Internet of Things (IoT) applications and blockchain technology. IoT devices facilitate real-time monitoring of temperature and humidity levels during transportation, allowing stakeholders to maintain optimal conditions. These sensors gather data continuously, sending alerts to relevant personnel if deviations from set parameters occur, thereby mitigating the risks associated with spoilage and loss.

Additionally, blockchain technology plays a crucial role in ensuring transparency and accountability throughout the cold chain process. By creating an immutable record of transactions and movements, blockchain allows for end-to-end traceability of products. This not only builds trust among consumers but also assists businesses in identifying any inefficiencies or delays in the supply chain. The adoption of these technologies leads to improved tracking capabilities, enabling companies to respond swiftly to potential issues, thus maintaining the integrity of temperature-sensitive products.

Moreover, advancements in automated temperature monitoring systems have transformed the landscape of cold chain logistics. These systems utilize advanced algorithms to predict and adjust refrigeration settings dynamically, ensuring that products remain within the required temperature range throughout the supply chain. This level of automation minimizes human error and enhances operational reliability, making it easier for companies to adhere to strict regulatory standards.

Furthermore, energy-efficient transport methods are gaining traction in cold chain logistics. These approaches incorporate eco-friendly vehicles and advanced insulation materials to reduce energy usage while maintaining the desired temperature for cargo. By adopting these innovative practices, businesses not only comply with environmental regulations but also reduce operational costs, ultimately leading to a more sustainable cold chain logistics model.

The Economic Impact of Cold Chain Logistics

Cold chain logistics plays a pivotal role in the economic landscape, particularly for industries reliant on the preservation and transportation of perishable goods, including food and pharmaceuticals. Efficient cold chain operations significantly contribute to reducing overall costs, increasing profitability, and enhancing marketplace competitiveness. By maintaining optimal temperature conditions throughout the supply chain, businesses can minimize spoilage and waste, which in turn leads to lower operational costs. This efficiency not only preserves the value of their products but also ensures compliance with food safety standards and regulations, which is crucial for consumer trust and brand reputation.

A well-managed cold chain allows companies to expand their market reach without compromising the quality of their products. For instance, businesses can transport perishable goods over longer distances, thereby tapping into new customer bases and potentially increasing sales. Moreover, companies that effectively implement cold chain logistics can benefit from improved inventory management and reduced storage costs. By minimizing product losses and streamlining operations, businesses position themselves to increase profit margins and gain a competitive edge over those that fail to invest in these logistics operations.

Conversely, inadequate cold chain practices can pose substantial financial risks. Losses from product spoilage due to improper temperature management are not only detrimental to revenue but can also lead to legal liabilities if health standards are violated. Additionally, the inability to maintain an efficient cold chain may force companies to invest in reactive measures, such as expediting shipments or discarding spoiled goods, which incurs additional costs. Ultimately, the economic impact of cold chain logistics is profound; investing in robust systems not only strengthens a company’s financial stability but also supports sustainable growth in the long run.

Regulatory Standards and Compliance

The regulatory landscape surrounding cold chain logistics is intricate, reflecting the critical nature of maintaining product integrity, especially in the food and pharmaceutical sectors. Various regional and international bodies have established guidelines to ensure that temperature-sensitive products remain safe from production to consumption. These regulations, often intricate and diverse, underscore the importance of compliance in preventing foodborne illnesses and safeguarding the quality of perishable goods.

In the United States, for instance, the Food and Drug Administration (FDA) administers regulations that mandate specific temperature controls for food and drug products. For example, food establishments must maintain cold storage temperatures at or below 40°F (4°C) to inhibit bacterial growth. Similarly, the U.S. Department of Agriculture (USDA) has set forth guidelines that govern the transportation and storage of meat, poultry, and eggs, emphasizing temperature maintenance to mitigate health risks.

Internationally, the World Health Organization (WHO) and the Codex Alimentarius Commission have developed guidelines that promote food safety through effective cold chain management. Countries adopting these standards are expected to implement strict temperature controls and monitoring systems to ensure compliance. The European Union (EU) similarly enforces regulations under the General Food Law, which mandates that food businesses ensure their products are safe throughout the supply chain, necessitating rigorous temperature monitoring.

Compliance with these regulatory standards is not merely about adherence; it plays a pivotal role in maintaining product quality and consumer trust. Non-compliance can lead to severe repercussions, including health crises stemming from foodborne pathogens and significant financial losses from product recalls. Therefore, investing in robust cold chain logistics that align with these guidelines is integral for businesses aiming to uphold safety and maintain high product standards.

Best Practices in Cold Chain Management

To enhance cold chain logistics, it is imperative for companies to adopt specific best practices that drive efficiency and reliability. One of the fundamental practices is the implementation of regular training programs for staff involved in cold chain operations. Such training not only equips employees with vital knowledge about temperature control and product handling but also emphasizes the importance of compliance with regulations and standards. By fostering a culture of continuous learning, organizations can ensure that their teams are well-prepared to maintain the integrity of temperature-sensitive products throughout the supply chain.

Another critical element in effective cold chain management is leveraging technology for real-time monitoring. The use of temperature sensors and tracking systems can significantly enhance visibility across the cold chain. By employing Internet of Things (IoT) devices, companies can monitor temperature fluctuations and humidity levels during storage and transit. Advanced analytics can be applied to this data to identify trends, predict failures, and make informed decisions. Implementing a centralized dashboard for monitoring can further streamline operations, enabling swift responses to any deviations that may jeopardize product quality.

Moreover, establishing contingency plans for equipment failures is vital in maintaining operational continuity and safeguarding product integrity. Companies should conduct regular assessments of their cold storage equipment and transportation vehicles to ensure they are in optimal condition. In addition, creating a robust emergency response plan can help mitigate risks associated with equipment breakdowns or unexpected temperature excursions. Having backup systems, such as alternate refrigeration sources and emergency response teams, can further ensure operational resilience.

By implementing these best practices, organizations can significantly improve their cold chain logistics. This, in turn, enhances product safety, reduces waste, and maintains customer trust in the reliability of temperature-sensitive items. Adopting a proactive approach and continuously evaluating and refining logistics processes will lead to long-term success in cold chain management.

Future Trends in Cold Chain Logistics

The cold chain logistics sector is poised for significant transformation as emerging trends reshape its landscape. As businesses increasingly recognize the importance of efficient temperature-controlled supply chains, several trends are surfacing that promise to enhance operations and sustainability. One of the foremost trends is the growing emphasis on sustainability. With environmental concerns gaining traction, logistics providers are exploring eco-friendly practices, such as utilizing energy-efficient refrigerated transportation and biodegradable packaging materials. These practices aim to reduce the carbon footprint while maintaining the integrity of temperature-sensitive products.

Another trend significantly impacting the cold chain logistics is the rise of e-commerce. As online shopping becomes more prevalent, consumer demand for perishable goods, pharmaceuticals, and other temperature-sensitive products is surging. The logistics industry must adapt by ensuring a swift, reliable, and efficient cold chain system that can accommodate the unique requirements of e-commerce deliveries. This includes implementing real-time tracking technologies and optimizing last-mile delivery strategies to ensure goods remain at optimal temperatures throughout the distribution process.

Advancements in temperature-sensitive packaging also represent a pivotal trend within cold chain logistics. As technology evolves, solutions such as advanced insulation materials, phase change materials, and smart packaging equipped with IoT sensors are being developed. These innovations enable better temperature control, provide real-time monitoring, and enhance traceability within the supply chain. This not only ensures product safety but also improves customer satisfaction by maintaining the quality of perishable items.

As the cold chain logistics sector evolves, businesses must remain vigilant and agile in adapting to these trends. By investing in sustainable practices, adapting to the demands of e-commerce, and integrating advanced packaging solutions, companies can position themselves to meet future challenges while capitalizing on new opportunities.